Handling technology

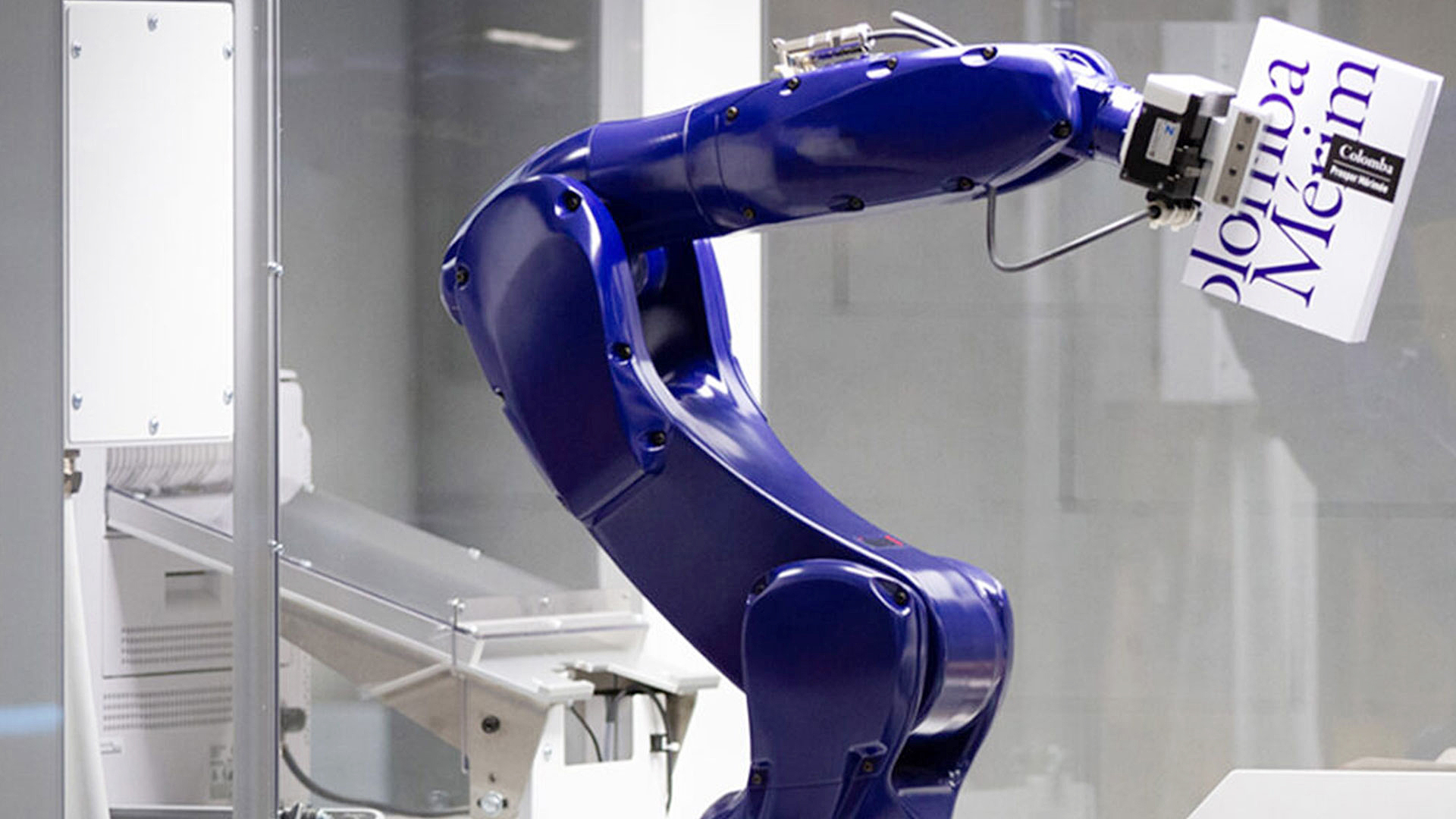

With over 40 years of experience, we are one of the leading manufacturers and suppliers of pneumatic, pneumatic-intelligent and electric handling components and systems.

Handling technology components

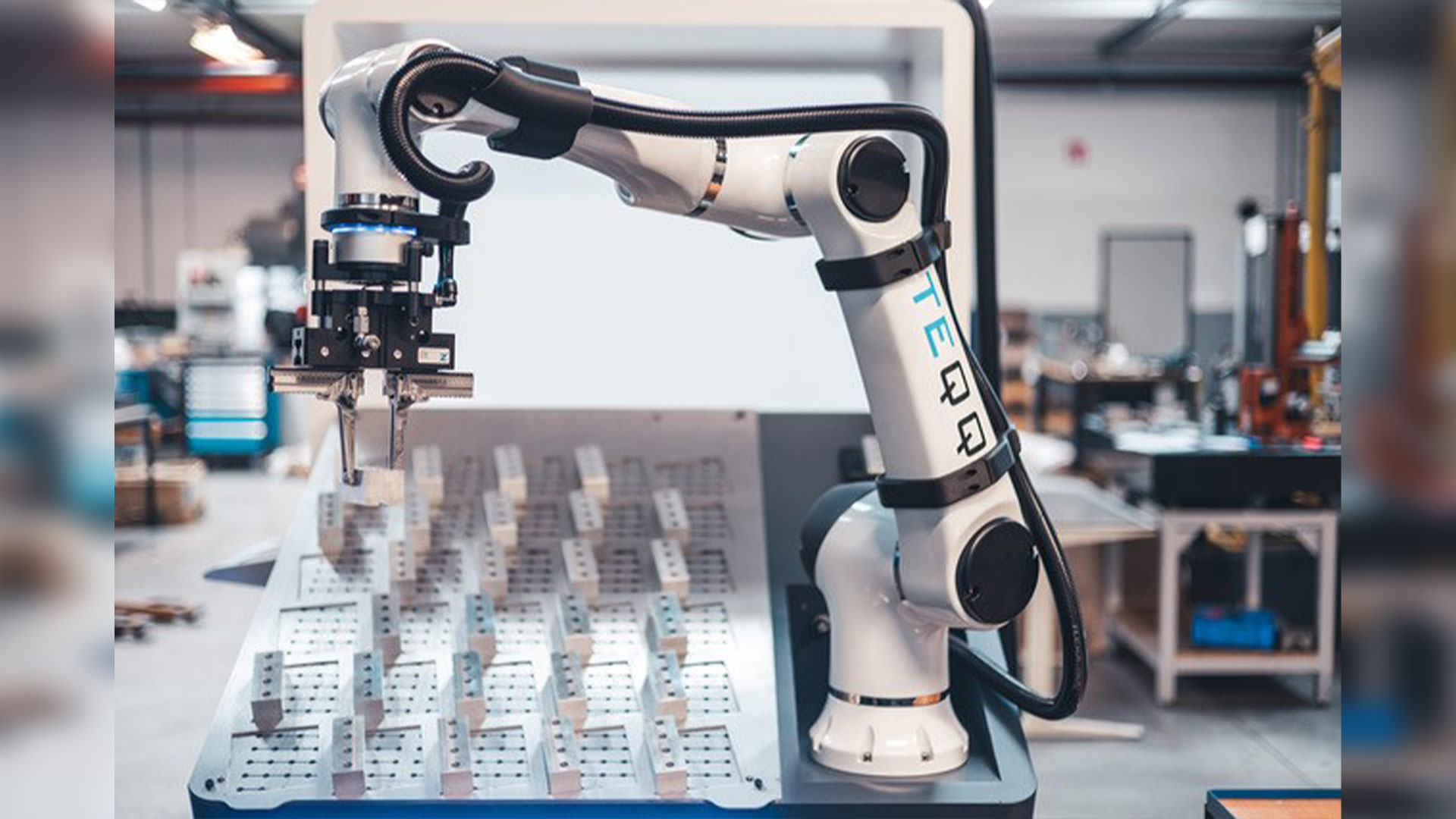

GRIPPING. ROTATING. SWIVELING.

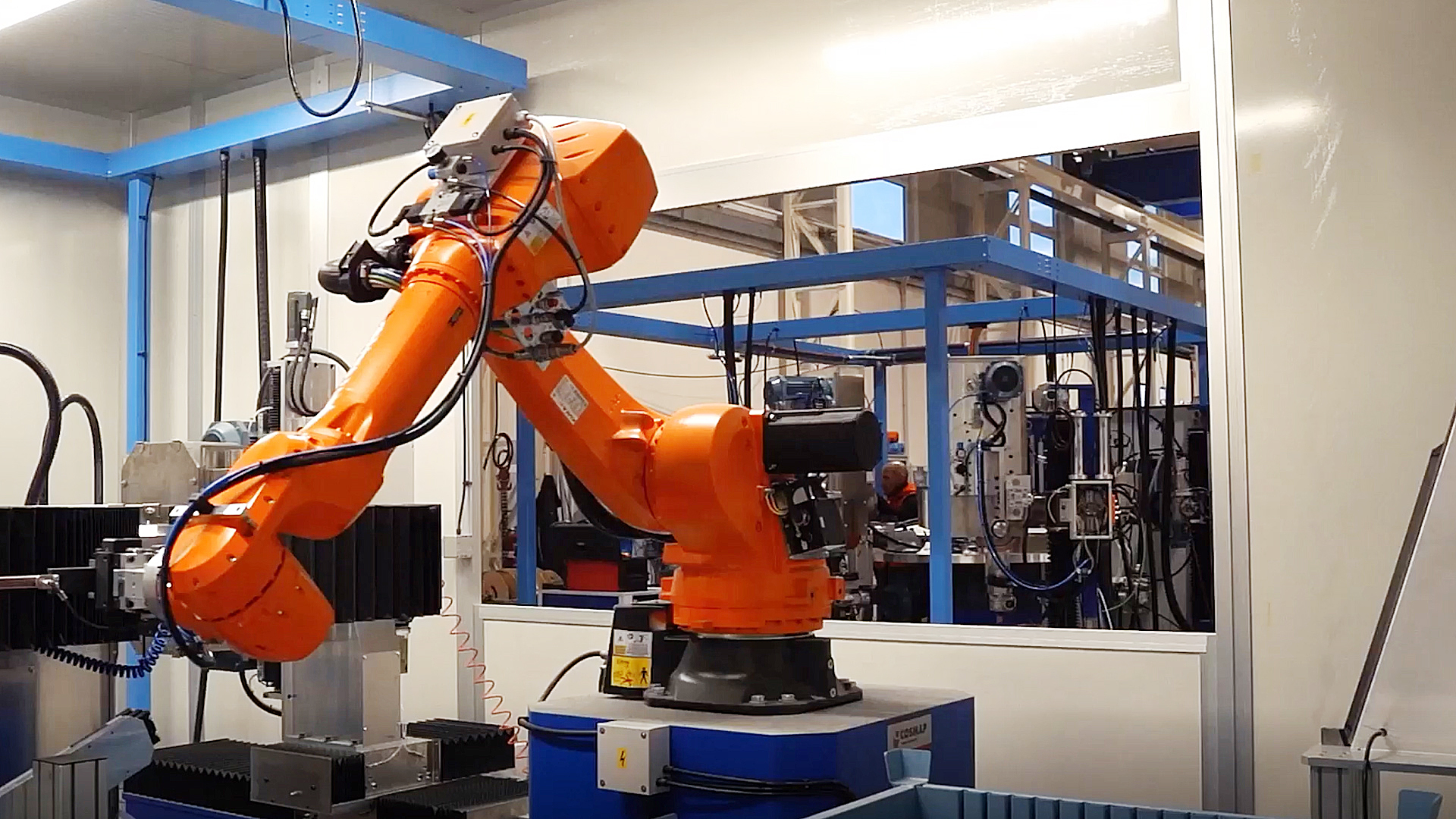

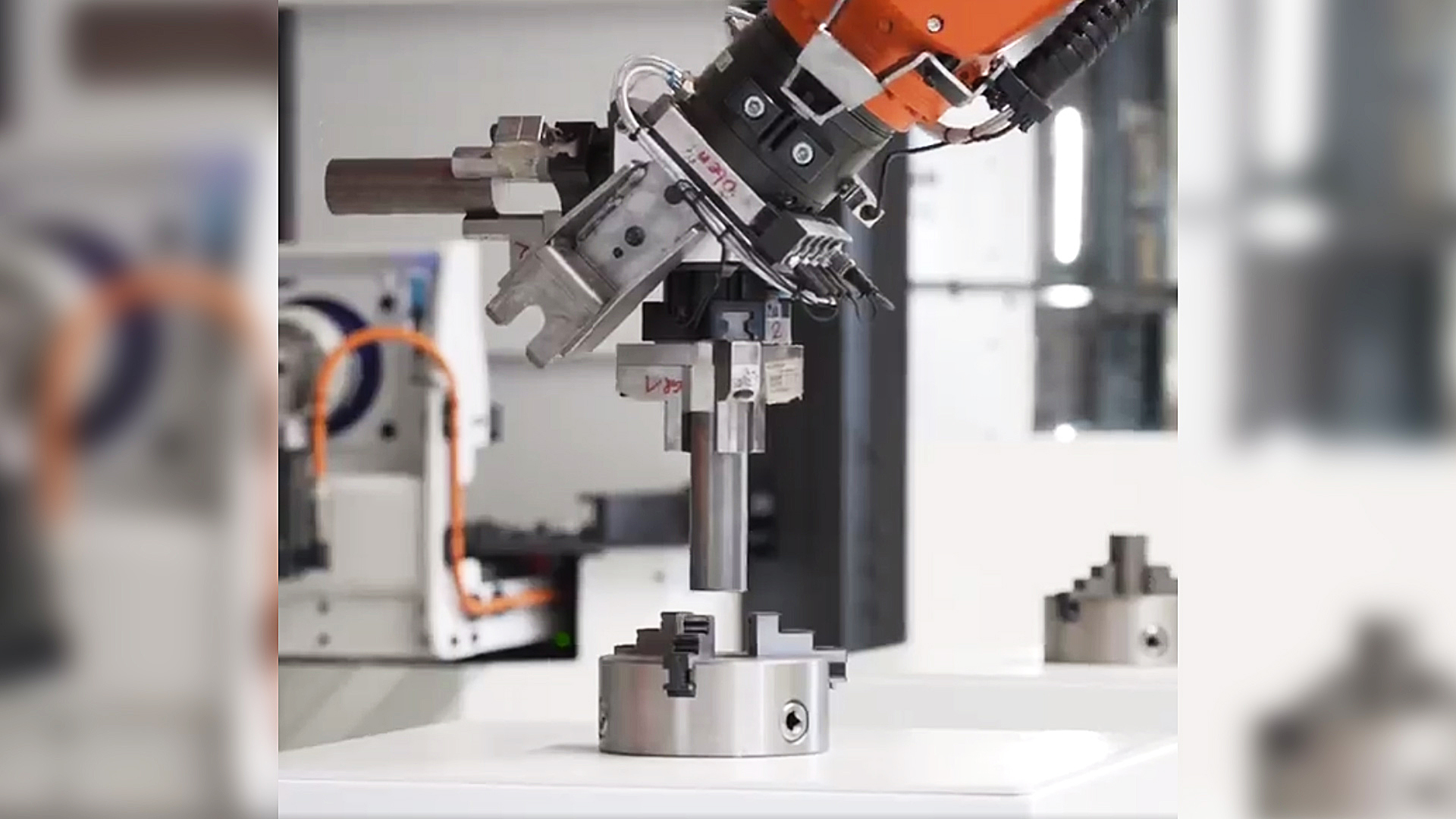

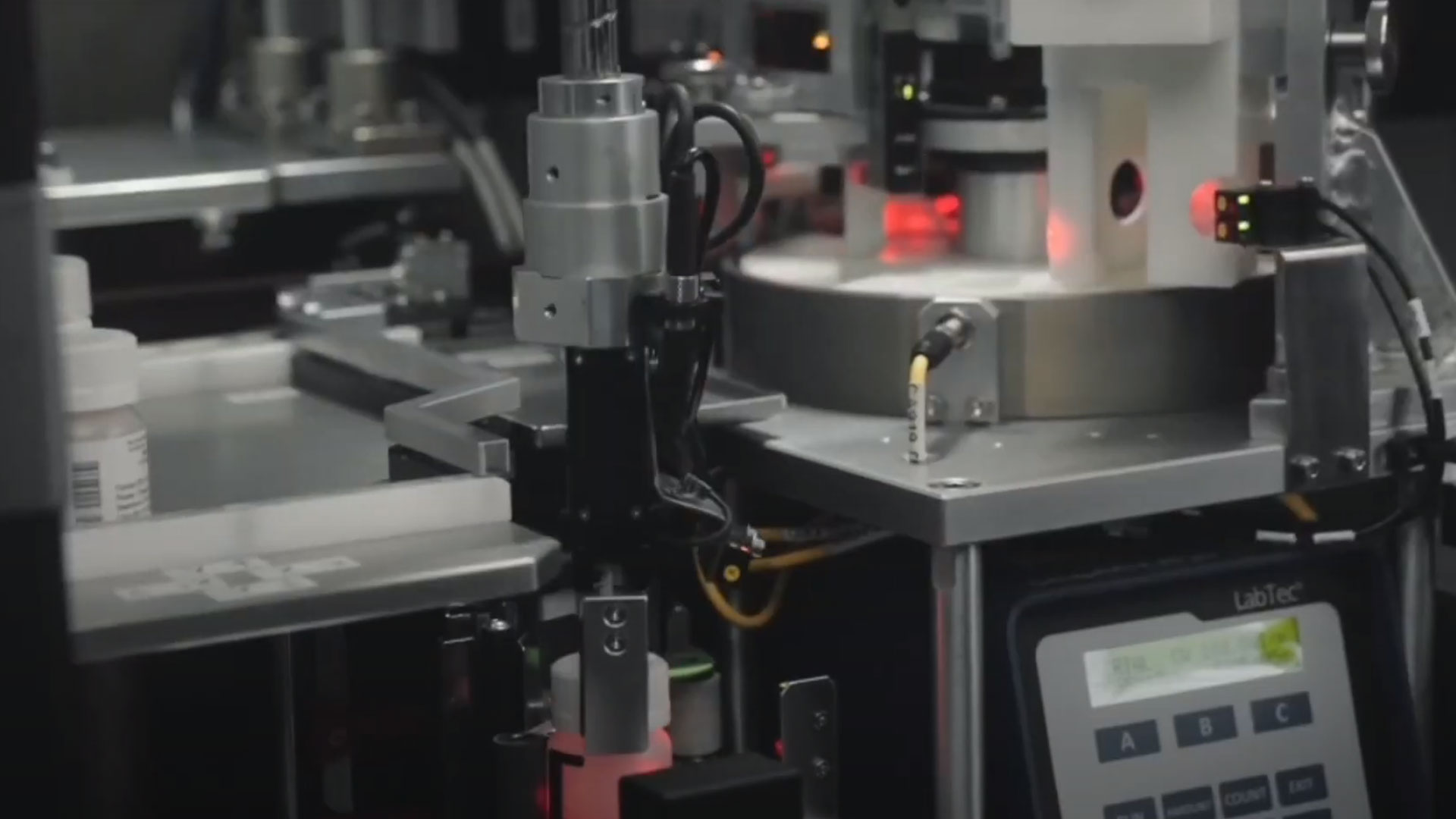

In handling technology, workpieces or tools are manipulated automatically within the industrial field. The technology behind our products is derived from the diverse movement possibilities of the human hand. This opens up a seemingly infinite number of handling options.

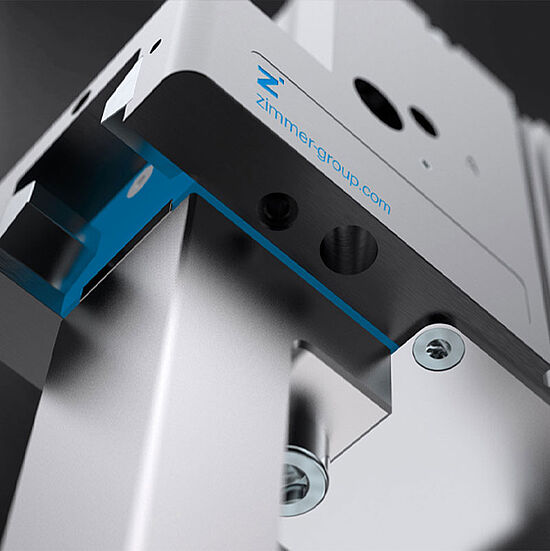

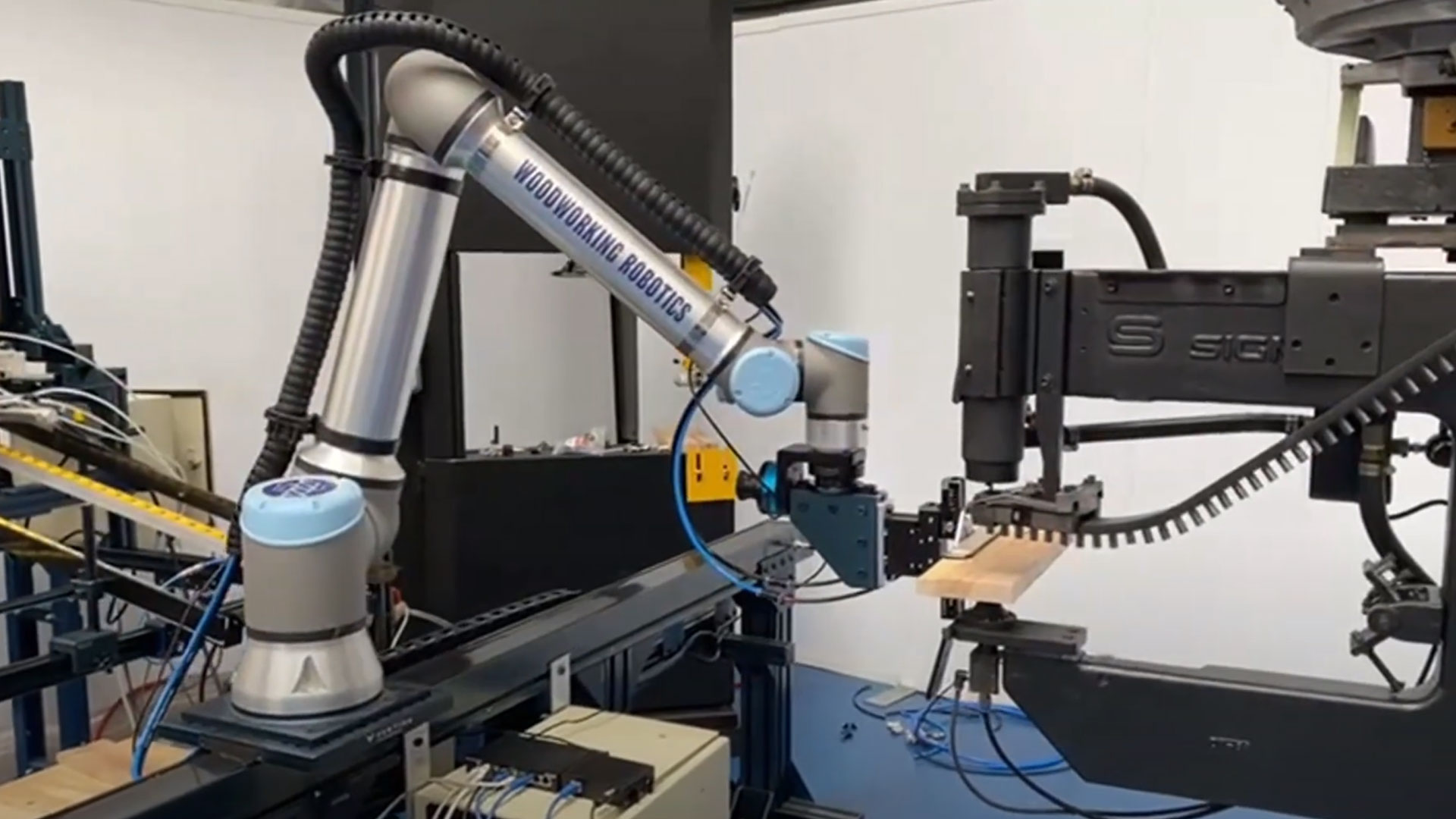

World market. The Zimmer Group is one of the world’s leading manufacturers and suppliers of pneumatic and electrical handling components and systems – with over 40 years of experience. Our portfolio is as broad as it is deep. Our own research and development work has produced exemplary innovations for process automation.

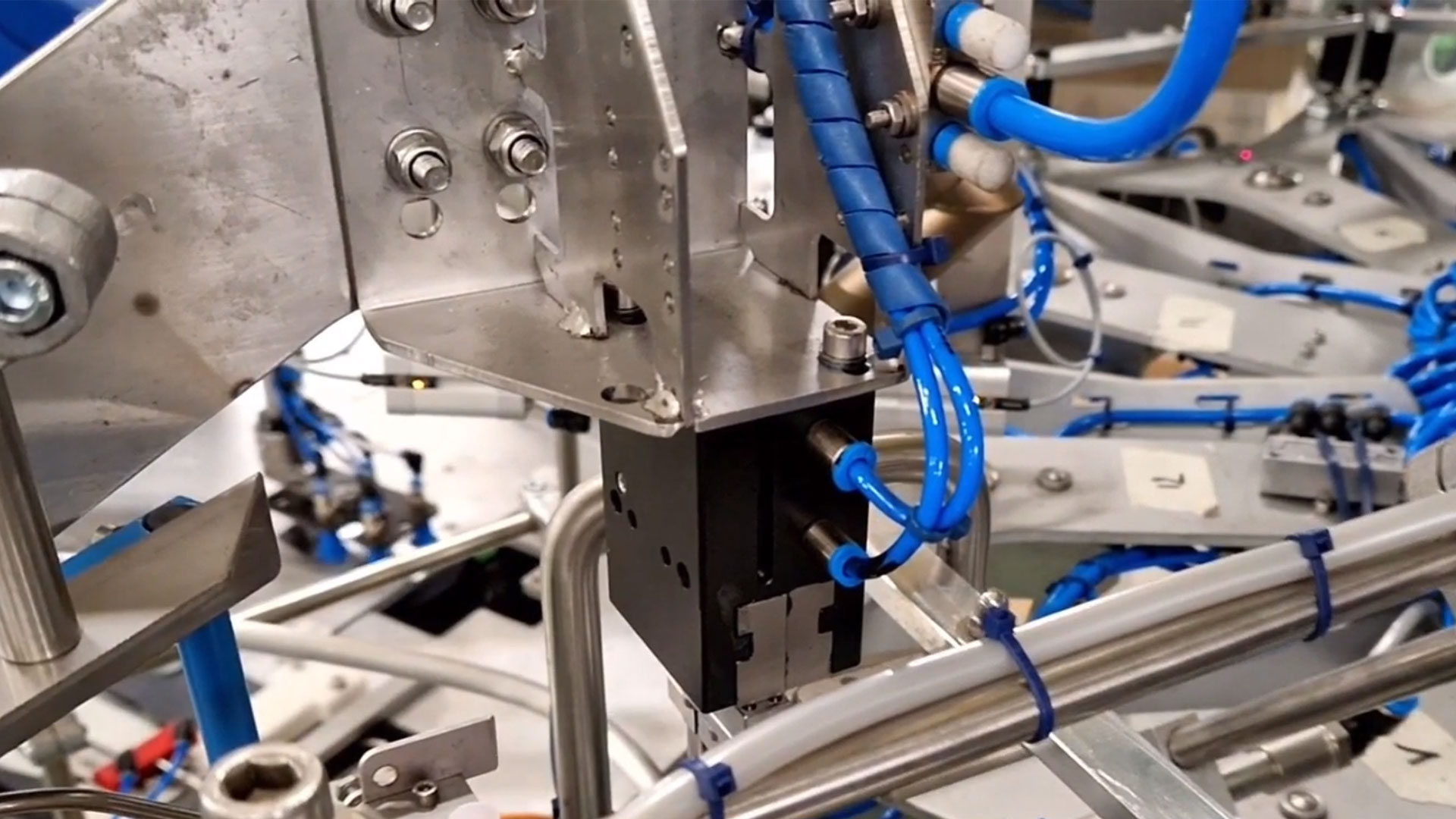

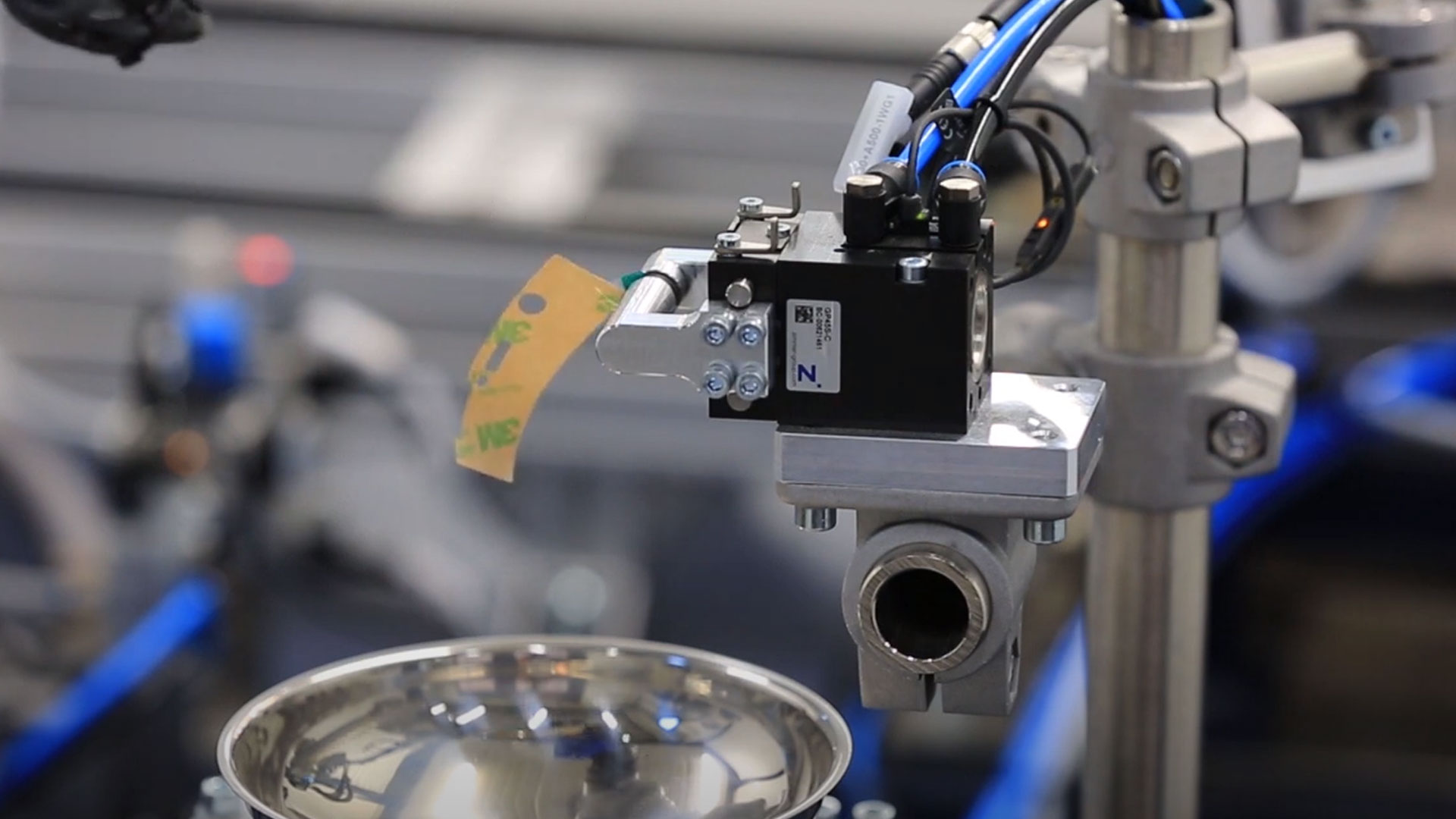

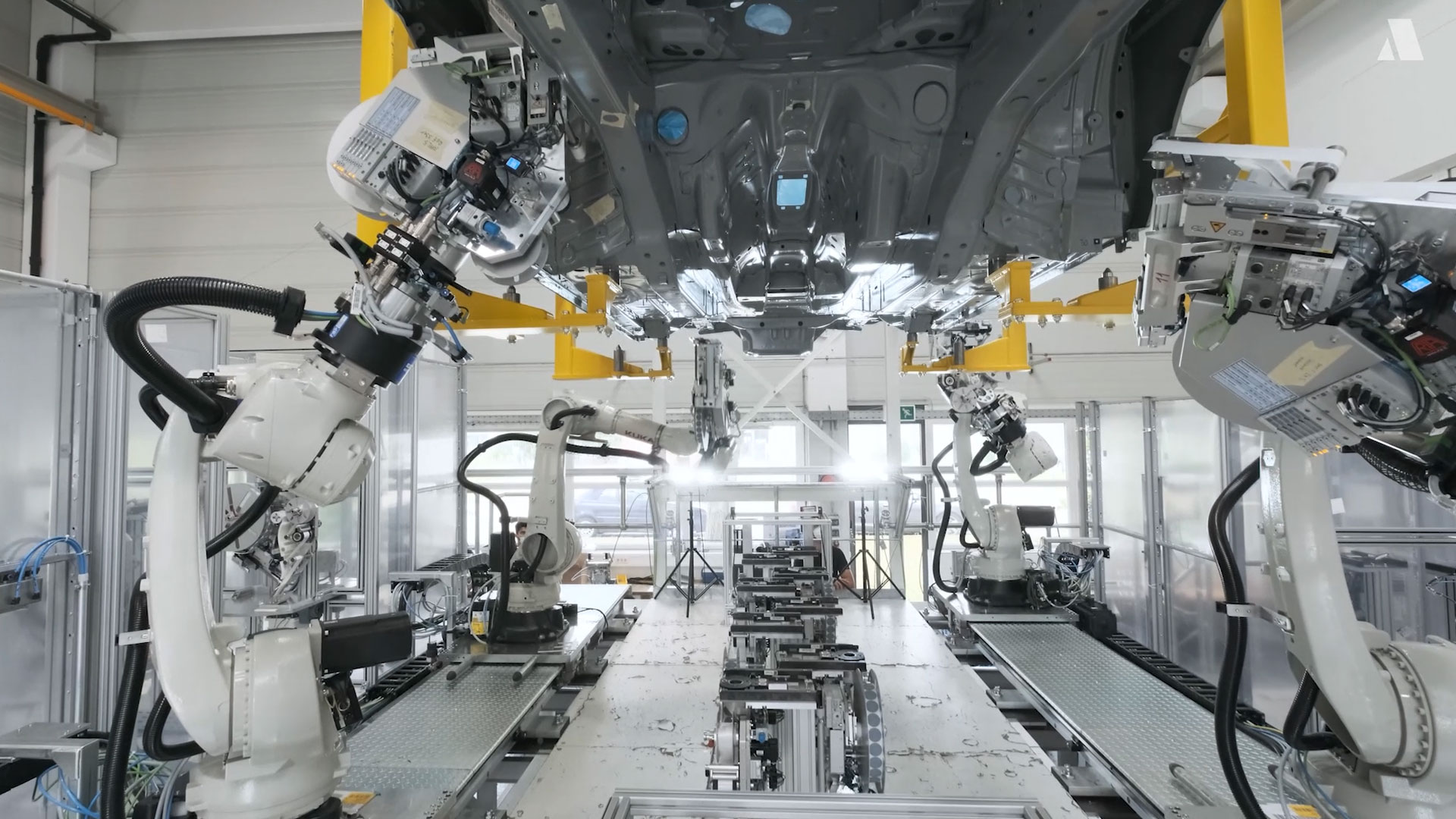

Customer solutions. We are expert contacts for your specific requests and develop components and systems for you. For us, customer-specific solutions mean: We are flexible when it comes to technology, processes, engineering and costs.

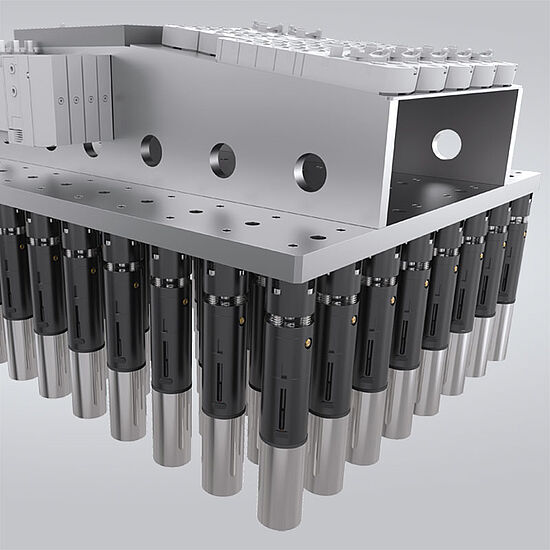

Components. More than 3,000 standardized grippers, pivot units, robotics and much more. We offer a complete selection of technologically leading products that are ready for rapid delivery.

Semi-standard. Our modular approach to design enables custom configurations and high rates of innovation for process automation.

The Zimmer Group serves all industries and offers:

- around 3,000 catalog products

- customer-specific solutions

- ready-to-install gripping and handling systems

- individualized service

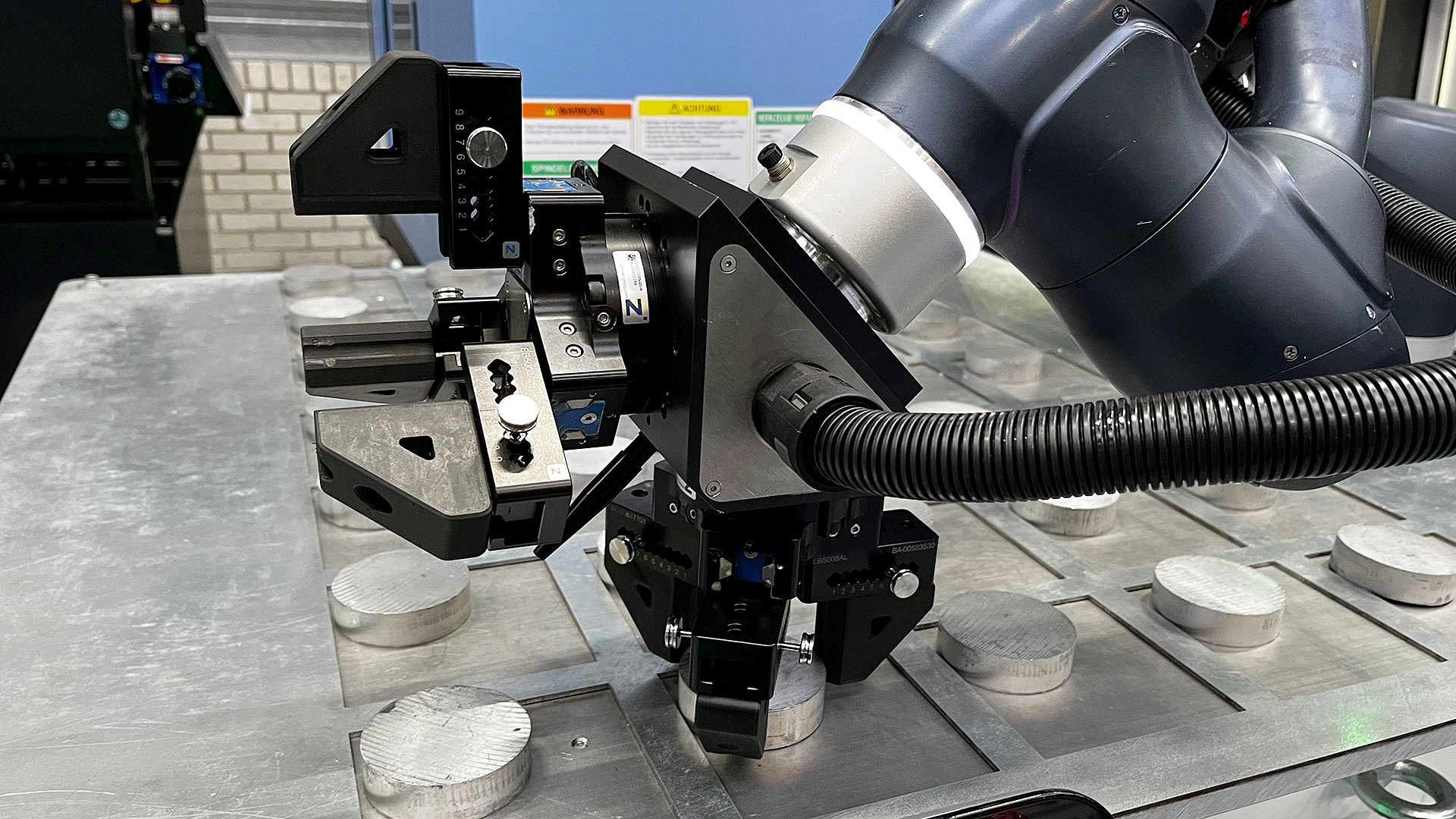

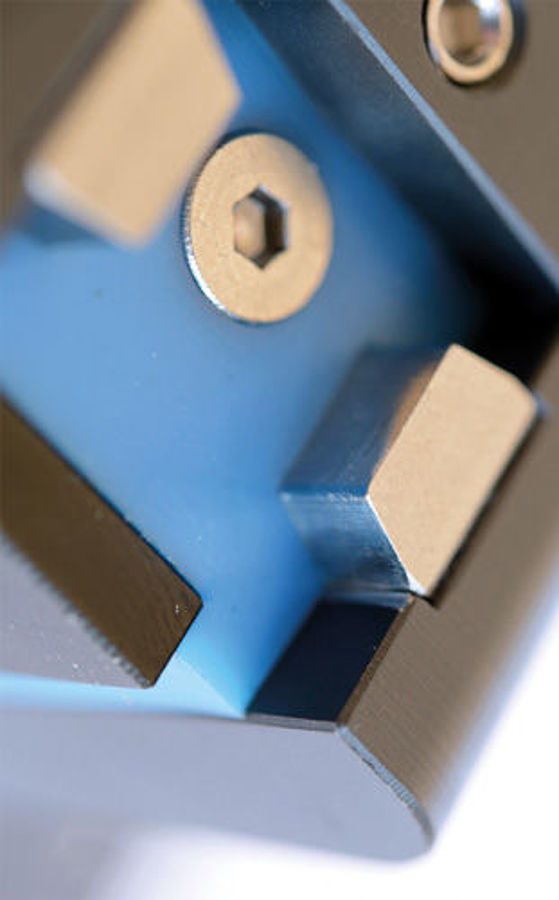

Technology highlight: Zimmer Group gripper

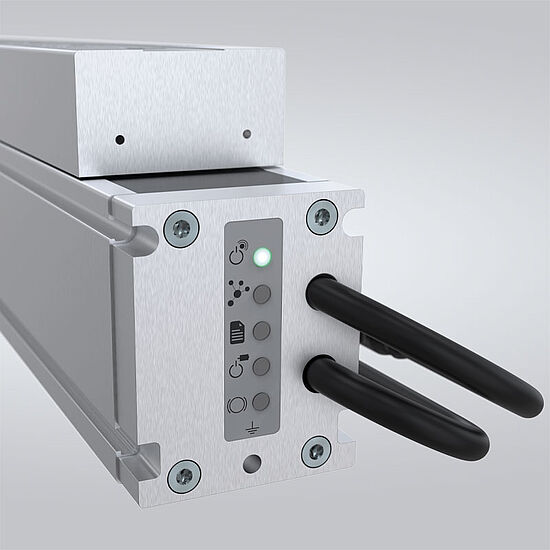

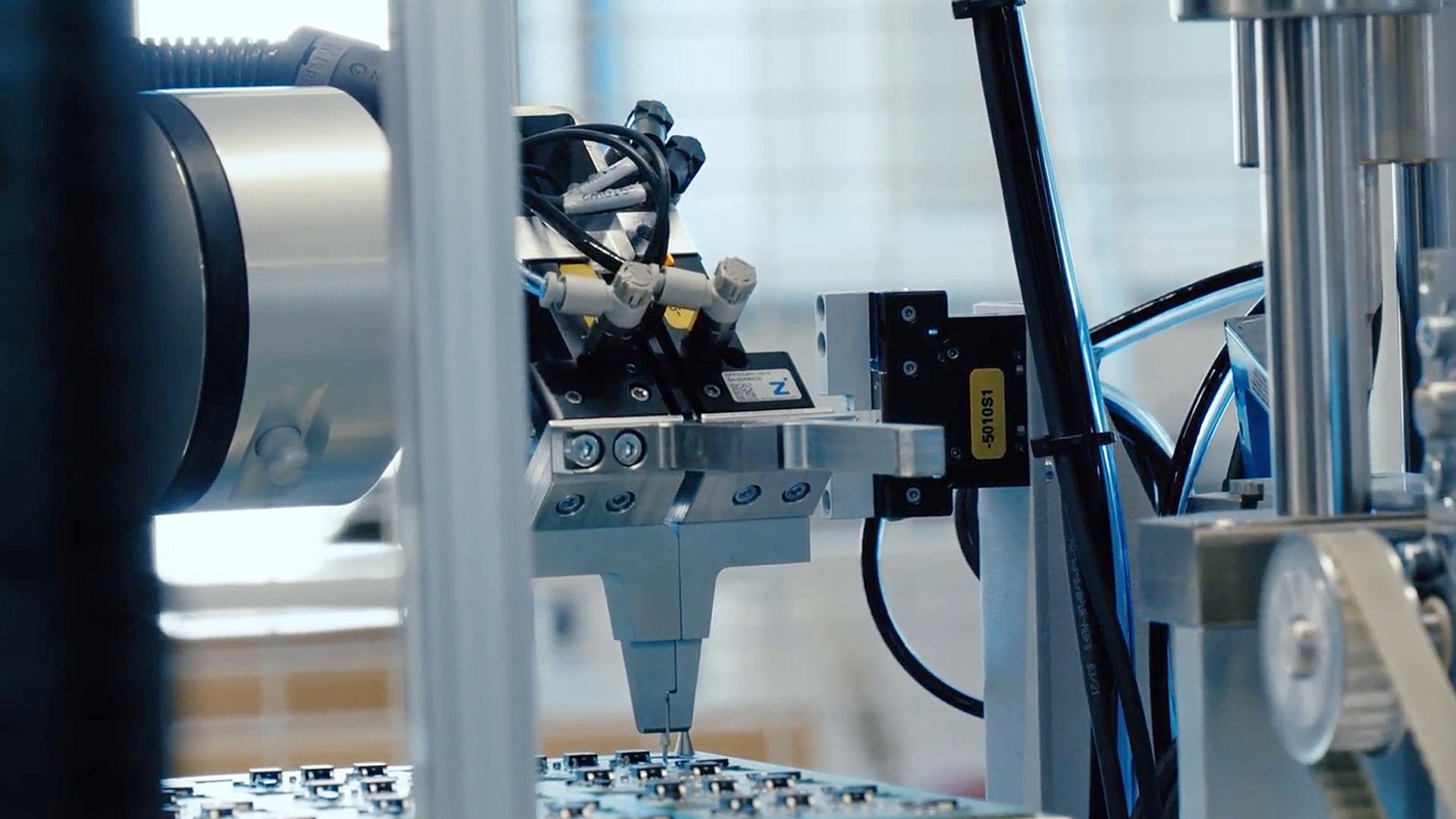

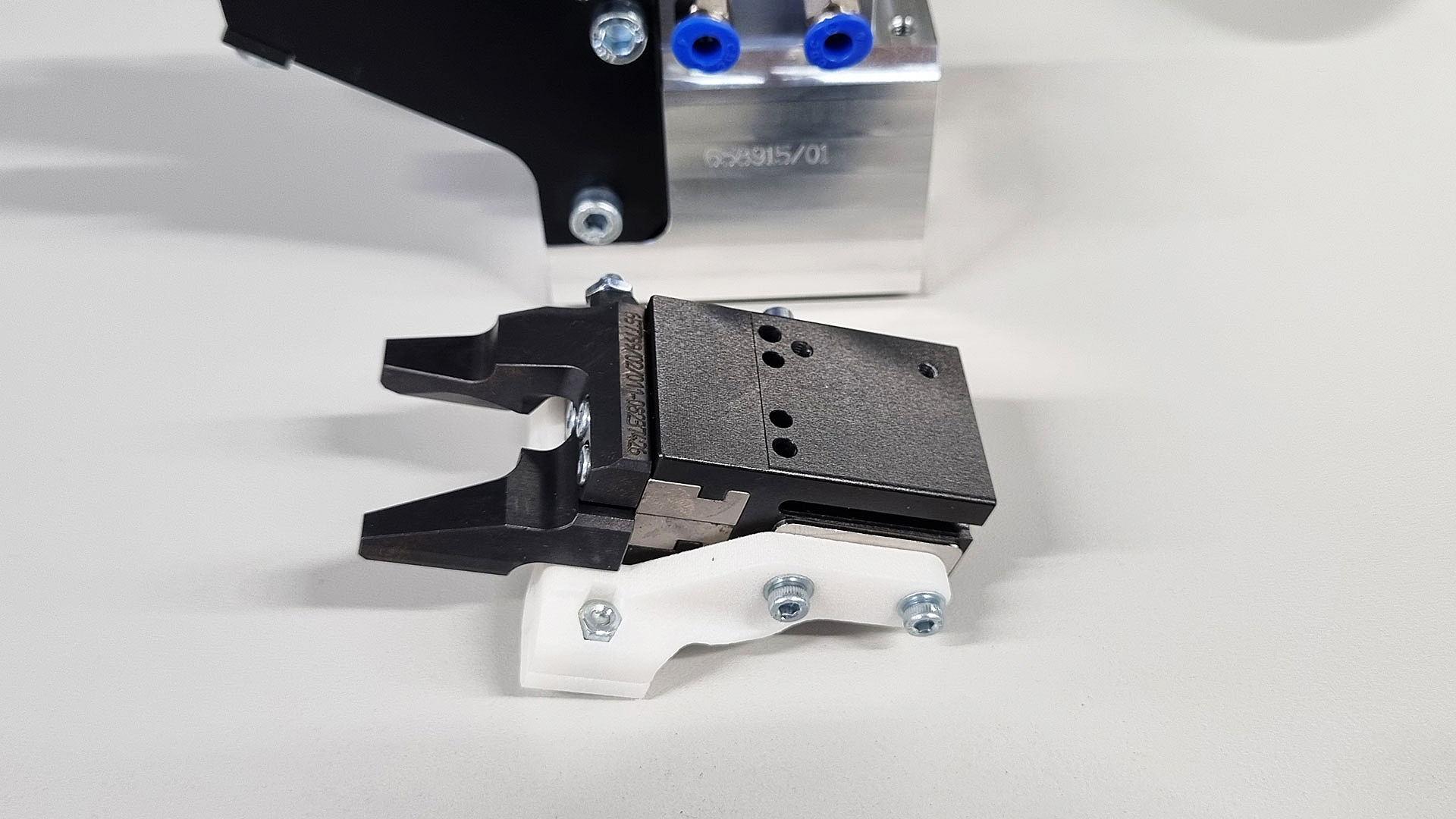

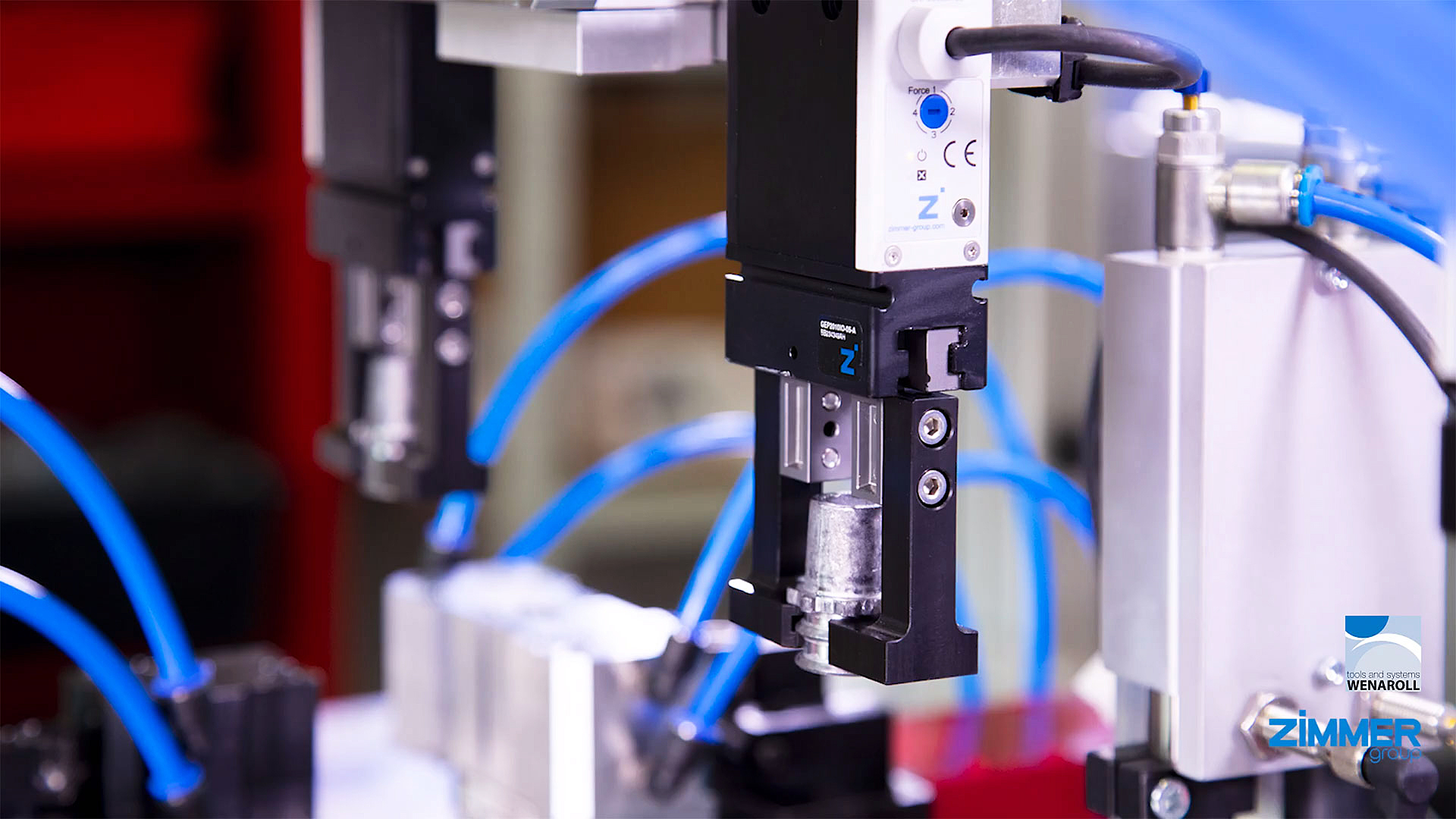

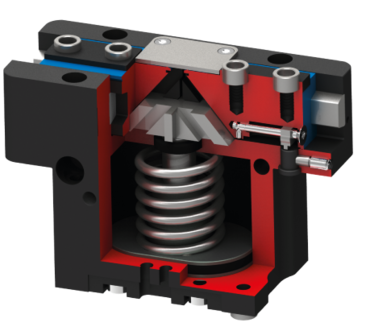

- Steel Linear Guide – The superior guide concept: The steel/steel guide features lasting precision, robustness and durability with maintenance intervals of up to 30 million gripping cycles. Benefit from these properties and use them to increase the efficiency and process reliability of your machine.

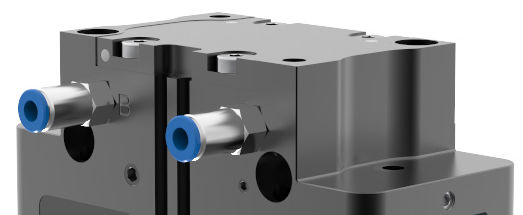

- Sealed and corrosion-protected – the universal gripper: Suitable for almost all environmental conditions, with a guide sealed up to IP67 and corrosion protection as standard, you can use this gripper universally. Reduce the variety of types in your production and the associated storage and process costs.

- Aluminum Linear Guide – The alternative: Reduced to the essentials, the steel / aluminum guide variant offers you significantly better performance than comparable grippers with T-slot guides and is on a par with most toothed guide principles.

Durable

Our product portfolio is tailored to the needs of our customers and provides a suitable solution for every application. The 5000 series offers you an all-around carefree package – with corrosion protection, IP67 and 30 million cycles without maintenance.

Universal

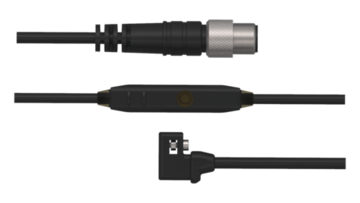

Mechatronic grippers make every production process more flexible. They have been an integral part of our product range since 1992 because they combine maximum performance with simple operation. The 5000 series combines features from pneumatics, electrical systems and hybrid technology.

PRECISE

We have been developing and continuously improving grippers since 1980. You will find these years of experience in all our grippers, but especially in our GPP5000 premium universal grippers.

EVERY WORKPIECE SECURELY GRIPPED – SUCCESS STORIES

FAQ – Questions and answers ON THE TOPIC OF HANDLING TECHNOLOGY

Handling technology deals with the automation of tasks such as gripping, moving and positioning workpieces or materials. It is used in industry, logistics and manufacturing.

Automated handling systems improve efficiency, reduce errors and lower labor costs. They enable precise positioning and increase production speed.

We differentiate between 2-jaw parallel grippers, 2-jaw angular grippers, 3-jaw angular grippers and vacuum grippers. There are also cutting tongs, distributors and specialized gripper types, such as needle or magnetic grippers, for specific shapes and materials. A particular challenge in handling technology is the safe cooperation between humans and robots. This is where HRC grippers with special safety features are used.

You can easily test which gripper is suitable for your application with our gripper Product Finder.