Innovative technologies for better patient care

Our automation solutions for medical technology offer state-of-the-art devices and systems for precise diagnosis, effective treatment and continuous monitoring. Our technologies improve patient care and increase efficiency in hospitals, clinics and doctors’ practices. Find out how our medical technology innovations optimize healthcare. Discover our solutions for medical technology here.

Do you need support with your med-tech application? We look forward to your inquiry and will be happy to advise you!

Your benefits:

- Maximum precision and efficiency

- Minimization of risks and complications

- Innovative technologies: Use of state-of-the-art components and systems

- Energy-efficient and resource-saving solutions

- Adaptability to various medical applications

- Robust and durable components for continuous operation

Application examples

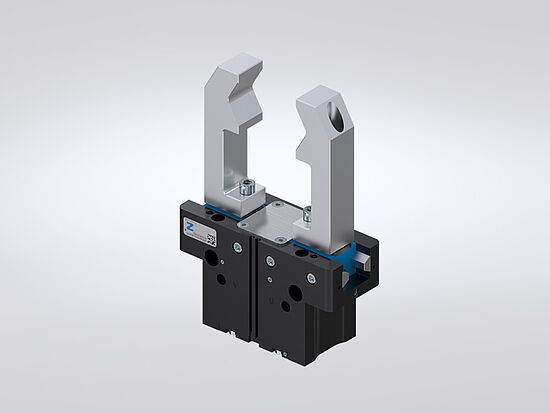

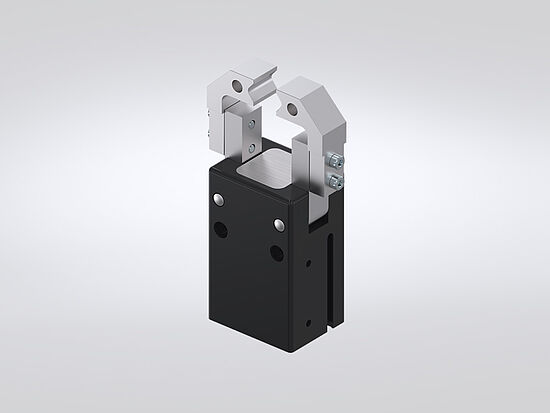

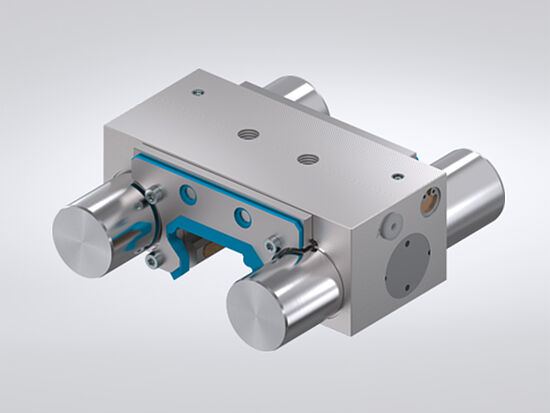

ELECTRIC CLAMPING ELEMENTS

LKE SERIES

Fast, efficient, flexible

The fast electric clamping elements are notable primarily because of their integrated status query, which is output via digital status signals. The kinematics are supplied by means of an eccentric shaft with a mechanical self-locking mechanism. Based on the self-locking functional principle, when closed, the full holding force is sustained in the event of a power drop or while in a de-energized state, ensuring accurate positioning.

INFORMATION

Energy efficient (bistable)

Integrated electronics

Flexible cable outlet

Available for all common profile rail guides

Emergency actuation

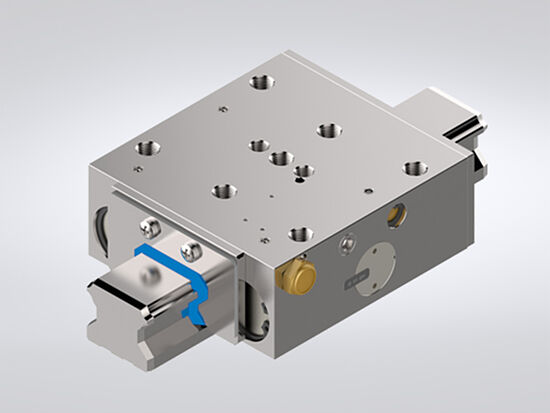

FASTENING OPERATING ROOM TABLES

Linear technology

De-energized clamping with status query

An electric clamping element is used to secure a patient table in place. The element features de-energized clamping and an integrated status query. In case of a power failure, the element can be opened manually at any time.

INFORMATION

Component

LKE electric clamping elementSpecial features

Securing operating room tables in place

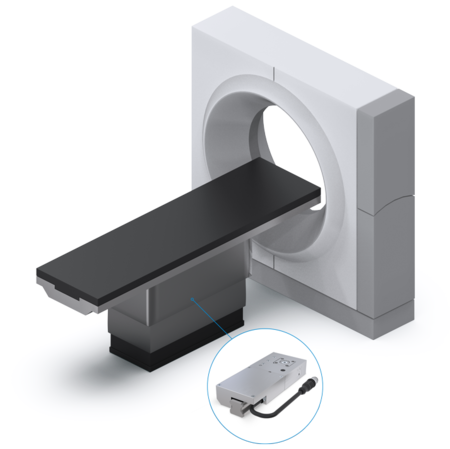

INDUSTRIAL SHOCK ABSORBERS

POWERSTOP PRODUCT FAMILY

Perfected for industry and medicine

The unique spiral groove technology is a defining feature of PowerStop industrial shock absorbers. In contrast with conventional industrial shock absorbers with throttle bores, the constantly tapering spiral groove causes precise, low-vibration damping absorption. They achieve maximum energy absorption with the smallest installation space through optimal utilization.

INFORMATION

Low-vibration damping

Bio oil

Hydrostatic piston guide

Stainless steel

Integrated oil reserve

Optimal protection can be selected

DAMPING PROSTHESES

Damping technology

Damping for greater comfort

Special shock absorbers (based on the PowerStop series) are used in prosthetic knee and hip joints for damping in the swing and standing phase. The dampers can be adjusted individually in the push and pull directions. The characteristic curve can be adapted to the movement sequences in the process. This enables high energy absorption in the smallest space.

INFORMATION

Component

Special shock absorbers (PowerStop product family)Special features

Individual adjustment and high energy absorption