STANDARD COMPONENTS AND CUSTOMIZED SOLUTIONS FOR THE MEDICAL AND PHARMACEUTICAL INDUSTRY

The Zimmer Group stands at the forefront of globally leading manufacturers of components for automation, machine and furniture damping, as well as process technology. Furthermore, with our individual solutions and wide-ranging experience, the Zimmer Group is an important partner of numerous well-known companies in the medical and pharmaceutical fields. As your reliable partner for this highly sensitive industry, we understand the importance of keeping product contamination to a minimum and minimizing the risk to operating personnel when handling hazardous substances. We are happy to support you in optimizing your automation process with our products.

Would you like advice on a specific project in the medical and pharmaceutical field? We look forward to your message!

Your benefits:

Even today, many standard products from all of our technology areas are capable of mastering many of these challenges.

- Hygienic design for easy cleaning and sterilization

- Resistant surfaces to aggressive cleaning agents such as hydrogen peroxide

- High IP protection classes for intensive cleaning

- Clean room conditions with reduced particle emission in accordance with GMP and ISO 14644

- Certified lubricants in accordance with the requirements of FDA regulation 21 CFR 178.3570

- Use of FDA-compliant materials

Any workpiece, any type of automation

Whichever product you are handling, we have the components you need. Is your application complicated? We gladly accept challenges such as this by also offering customer-specific complete system solutions.

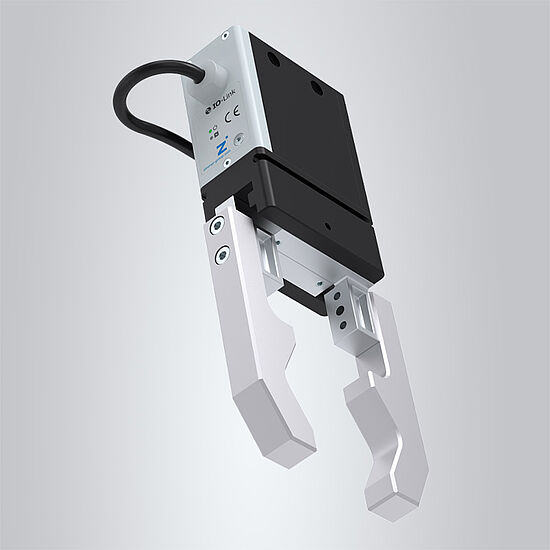

2-JAW PARALLEL GRIPPER

GEP2000 SERIES

The electric compact one

Behind the proven GEP2000 series are electric small parts grippers for medical and laboratory automation that feature, among other things, free positioning and workpiece loss detection. A key feature of the grippers is the mechanical self-locking mechanism, which ensures that the workpiece (e.g. an infectious sample tube) is held securely even in the event of a power failure or emergency stop.

10 million maintenance-free cycles (max.)

Integrated sensing

Mechanical self-locking mechanism

Magnetic field sensor

Adjustable gripping force

IO-Link

CUSTOMIZED GEP2000

HANDLING TECHNOLOGY

2-jaw parallel grippers

The customer-specific version based on the GEP2000 series features a seal that complies with protection class IP54. The use of food-safe H1 grease and hydrogen peroxide-resistant materials, the FDA-compliant design and the reduced particle emission in accordance with GMP make this semi-standard gripper ideal for medical and pharmaceutical applications.

Do you need an end effector yourself or do you have any questions? We will be happy to provide you with individual advice.

Benefits

- Hygienic design: sealed gripper module, axial connecting line

- Housing made of stainless steel, PEEK or PET: external steel parts made of 1.4404, gripper housing made of PET, protector seals made of FKM, other external seals made of silicone

- External parts H2O2-resistant

Hydrogen peroxide-resistant materials

Reduced particle emissions in accordance with GMP

FDA-compliant design

Protection class in accordance with IEC 60529

Food-grade H1 grease

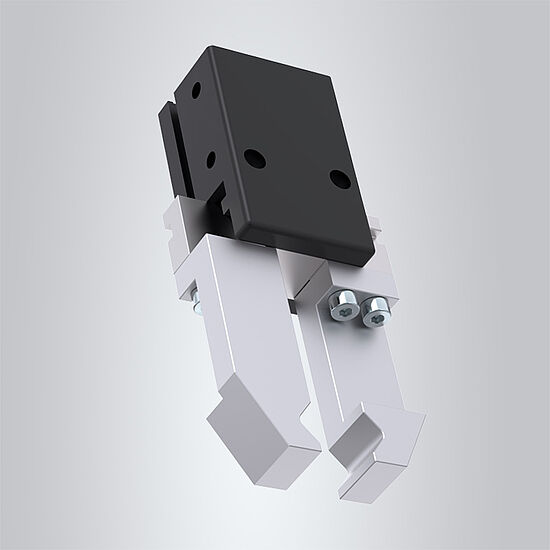

HANDLING OF glass vials

HANDLING TECHNOLOGY

Position detection identifies loss

The customized electric gripper is used to transport vials and syringes in a filling system. The integrated position detection of the gripper allows the various products to be detected and any loss to be recognized immediately.

INFORMATION

Component

Customer-specific solution based on the GEP2000 electric gripper seriesSpecial features

Hygienic design, IP65 Electronics module, media-resistant because of the use of stainless steel and PEEK, stroke lengthened to 11 mm per gripper jaw

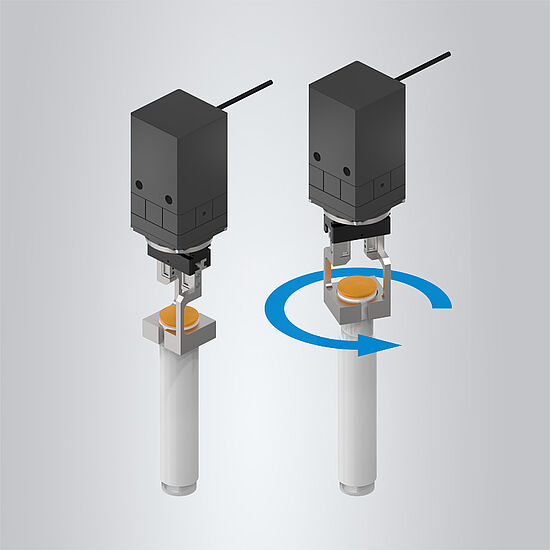

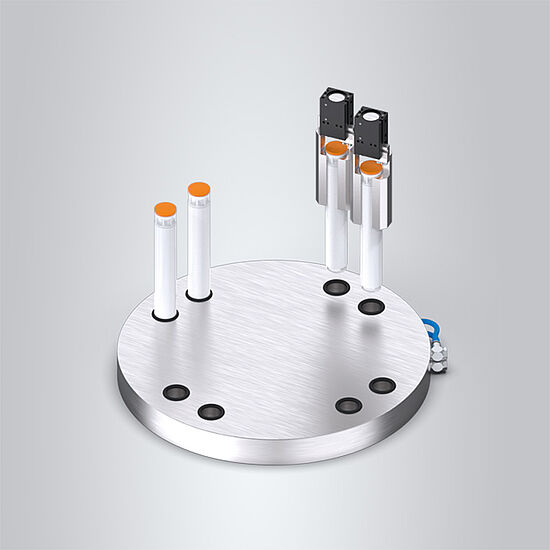

OPENING AND CLOSING SPECIMENS

HANDLING TECHNOLOGY

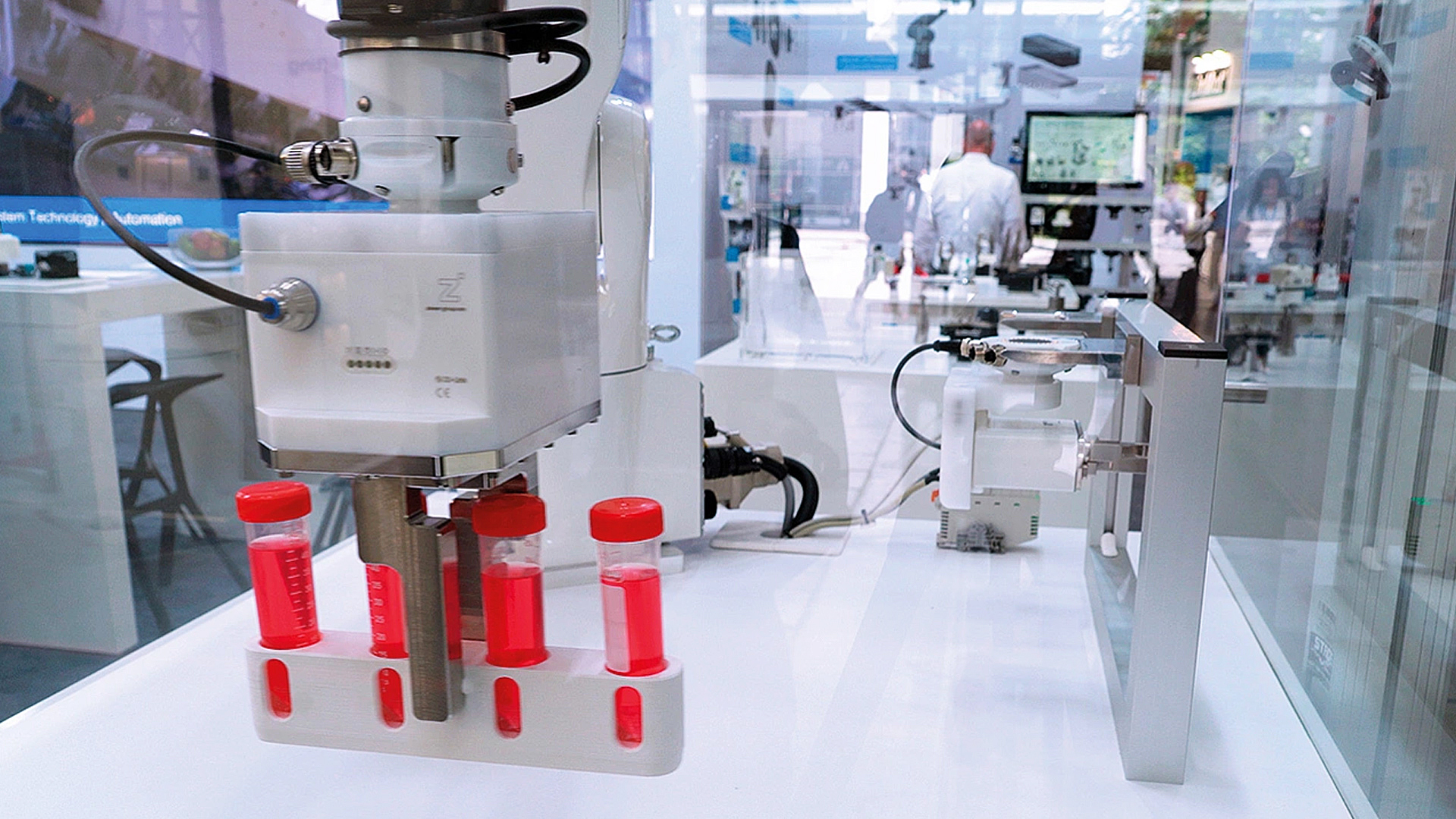

One component – two functions

This special handling solution serves as a decapper and recapper for sample tubes by combining turning and gripping. It is also used for labeling vials or aligning the barcode of sample tubes so that it can be scanned.

INFORMATION

Component

Customer-specific solution based on the GEP2000 gripper seriesSpecial features

Adjustable forces and positionability of the gripper and rotary module

2-JAW PARALLEL GRIPPER

MGP800 SERIES

The powerful one

For handling small parts such as test tubes, the Zimmer Group offers you the best in this field with pneumatic grippers from the MGP800 series. See their robustness, durability and performance for yourself and take a closer look at our smallest models – the lightest weighs just 0.008 kg.

10 million maintenance-free cycles (max.)

Magnetic field sensor

Spring closing C

IP40

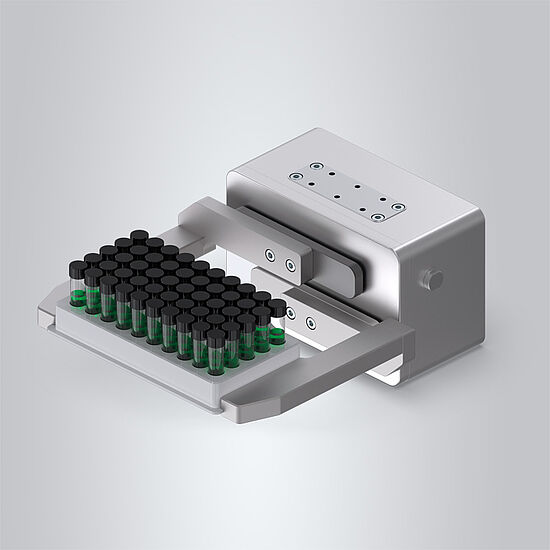

TRANSPORT OF INSULIN STICKS

HANDLING TECHNOLOGY

Standard grippers for individual solutions

A standard pneumatic gripper from the MGP800 series is used to transport insulin sticks in a production line. Thanks to the small design of the grippers, the pitch has been reduced to a minimum, allowing several grippers to be positioned next to each other.

INFORMATION

Component

MGP800 seriesSpecial features

Use of standard components makes adaptations unnecessary

2-JAW PARALLEL GRIPPER

GEH6000IL SERIES

The highest performer

The long-stroke electric grippers in the GEH6000IL series are equipped with a servo drive with integrated controller. The brushless drive technology guarantees individual force adjustment as well as position and speed control. Since laboratory automation usually involves working with fragile glass and plastic, the grippers also have a mechanical self-locking mechanism that prevents a vial from falling in the event of a power failure.

Positionable

Integrated sensing

IP54

Mechanical self-locking mechanism

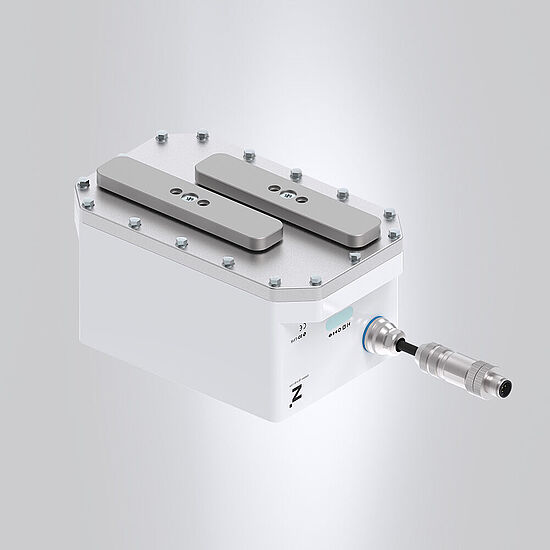

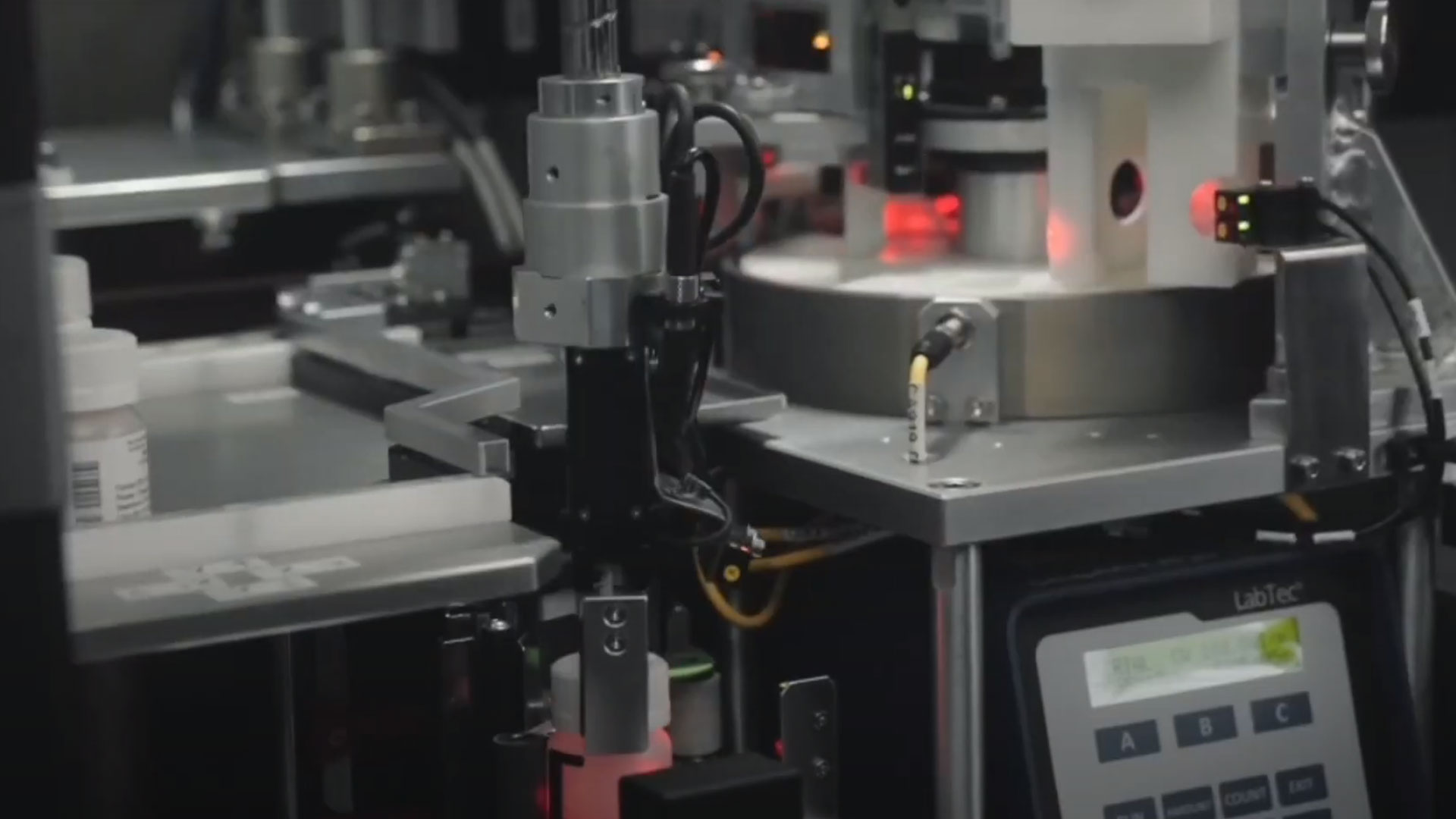

REAGENT GLASS HANDLING

HANDLING TECHNOLOGY

The best choice for safety and reliability

A positionable electric gripper was used for the highly sensitive transport of racks in laboratory automation. The adapted gripper, based on the proven GEH6000IL series, has a mechanical self-locking mechanism that prevents the rack from opening and therefore being lost in the event of a power failure.

INFORMATION

Component

Customer-specific solution based on the GEH6000IL electric gripper seriesSpecial features

Hygienic design, IP54, media-resistant because of the use of stainless steel

CUSTOMIZED GEH6000

HANDLING TECHNOLOGY

2-jaw parallel gripper with long stroke

With its IP65 protection class and FDA-compliant design, this customized 2-jaw parallel gripper with long stroke is particularly easy to clean and therefore also suitable for use in demanding environments. The reduced particle emission in accordance with GMP also ensures a clean working environment. The H1 lubrication makes it ideal for use in the food and pharmaceutical industries and it meets the highest level of hygiene requirements.

Do you have any questions or do you have an application for which you need an end effector with specific features? We will be happy to advise you individually. Get in touch with us now!

Benefits

- Emergency release possible from outside

- Hydrogen peroxide-resistant: housing made of PET, external steel parts made of 1.4404 or 1.4305, protector seals made of FKM

- Protector seal lubricated with clean room grease

- Hygienic design electronic module IP65

Hydrogen peroxide-resistant materials

Reduced particle emissions in accordance with GMP

FDA-compliant design

Protection class in accordance with IEC 60529

Food-grade H1 grease

Clean room class 3 in accordance with DIN EN ISO 14644-1

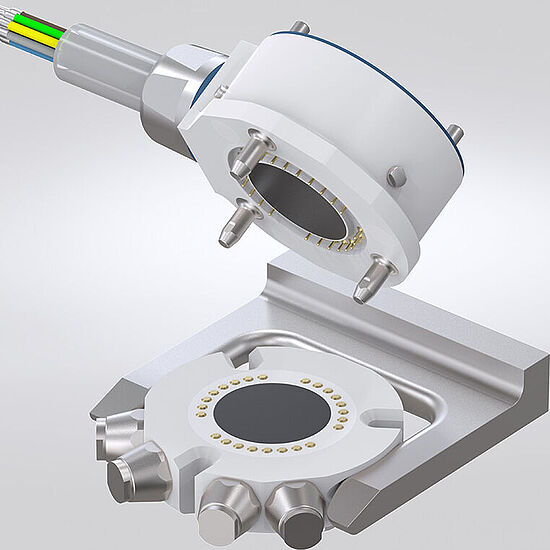

ROBOT ACCESSORIES IN HYGIENIC DESIGN

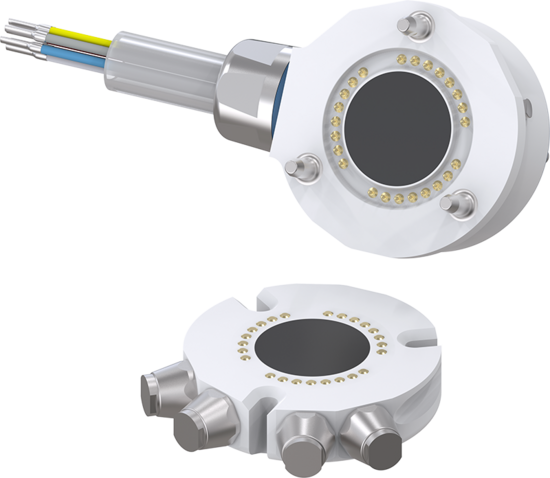

ASEPTIC TOOL CHANGER

In the pharmaceutical and medical industries, special requirements apply to hygiene, clean room classification and the lubricants used: a hygienic design that enables easy cleaning and sterilization, protects against corrosion and the ingress of dirt and bacteria and prevents contamination.

The Zimmer Group has developed a tool changer that meets the requirements of hygienic design. The changer, which has protection class IP67, is mainly made of PEEK (polyether ether ketone), which has made it possible to achieve a very low weight. The other materials used, such as stainless steel and PTFE (polytetrafluoroethylene), also ensure safe cleaning with the media commonly used in the industry, such as H2O2 (hydrogen peroxide).

A permanent electromagnet not only allows the loose parts to be changed magnetically, but also ensures that the tool and the workpiece remain connected in a de-energized state, for example in the event of an emergency stop or power failure. The rotation lock ensures rotational alignment between the stationary and loose parts and also ensures that the necessary torques are transmitted.

INFORMATION

Handling weight up to 10 kg

24 spring pins for transmitting different signals and currents

Integrated coding switch for differentiating between up to 7 different loose parts