Tool changers WPR5000 series

MAXIMUM FLEXIBILITY AND EFFICIENCY

OUR EXPERTISE – YOUR ADVANTAGES

Safe tool changer

The tool changer ensures maximum safety and meets the requirements of Performance Level d, Control Category 3. This is achieved by a spring-loaded piston, self-locking mechanism, optional sensors and other accessories.

Locking kinematics

A new benchmark for tool changers is set with innovative locking kinematics with locking bolts and extreme rigidity. The extremely flat design guarantees minimal torque load on the robot and allows smaller and more cost-effective robots to be used.

Endless variety

The energy elements of the WER1500 and WER3000 series allow the standardized transmission of pneumatics, hydraulics, electrical signals, power and communication and much more.

| Technical data | ||||

|---|---|---|---|---|

| Installation size | Connecting flange in accordance with EN ISO 9409-1 | Pneumatic power transmission [quantity] | Electric power transmission | |

| WPR5040 | TK 40 | 4 | optional | |

| WPR5050 | TK 50 | 4 | optional | |

| WPR5063 | TK 63 | 6 | optional | |

| WPR5080 | TK 80 | 6 | optional | |

| WPR5100 | TK 100 | 8 | optional | |

| WPR5125 | TK 125 | 10 | optional | |

| WPR5160 | TK 160 | 10 | optional | |

THE TECHNICAL FEATURES IN DETAIL

WPR5000 SERIES

COMPREHENSIVE RANGE OF ACCESSORIES

The WPR5000 series tool changers offer a comprehensive range of accessories that significantly increase the efficiency and user-friendliness of your automated processes. These accessories allow seamless integration into existing robotic applications and ensure maximum reliability and operating convenience.

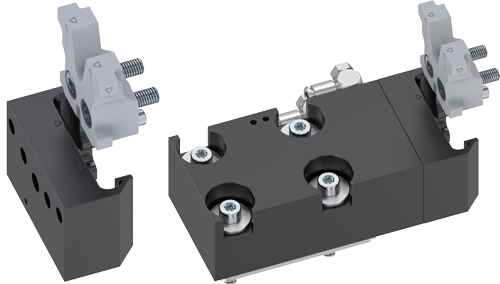

The storage station

Flexibility

Two storage stations have been developed for the WPR5000 series tool changer. With integrated in-plane axis compensation module and secure loose part locking or the classic variant.

Safety

The pneumatic spring-loaded locking mechanism integrated into the storage station ensures that the loose part can be placed in almost any spatial direction and is securely locked into it.

Sensors

The range of accessories is completed by optionally available sensors for sensing the locking mechanism in the storage station and the loose part.

Passive safety interlock

It is also possible to open the storage station at the right time entirely without active control using a passive interlock via the stationary part and to lock it again automatically.

Piston position sensing

The piston position sensing using 2-point magnetic field sensors enables simple and reliable position monitoring of the locking mechanism. Unlike conventional systems where the sensors are mounted on top of the tool changer, the WPR5000 series features side integration. This maximizes the use of the installation space and minimizes the interference contour of the tool changer.

Programming tips

The programming tips provide an intuitive and simple way to make the teaching and programming process as easy and efficient as possible for the user. In addition, there are also markings on the storage station and on the suspension system for the loose part that significantly simplify the process of setting up the tool changer on the robot.

Always the right transmitter

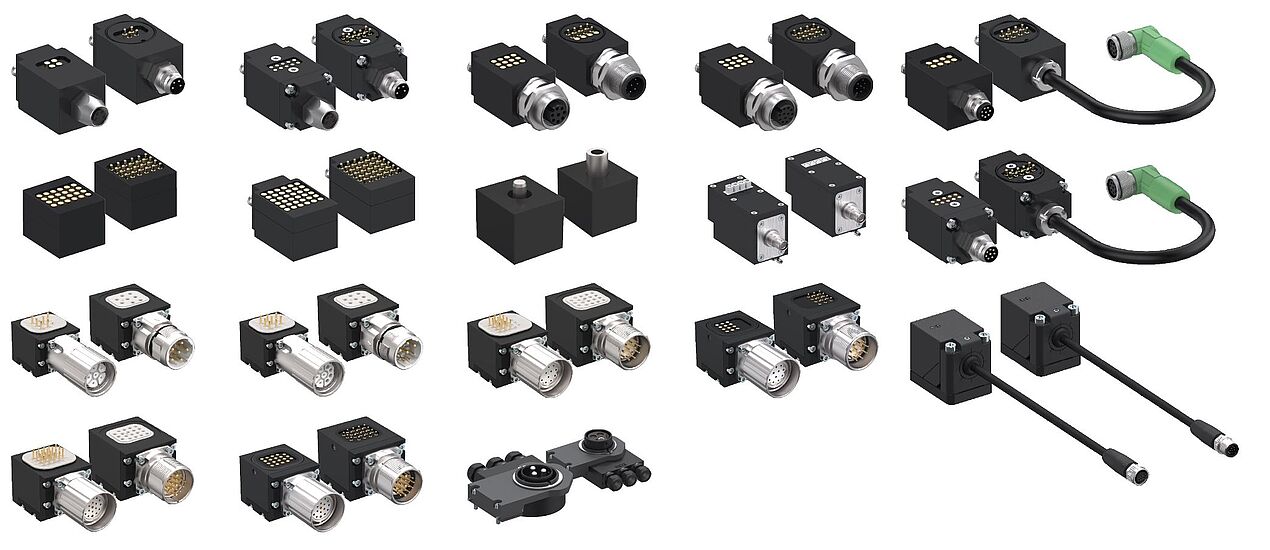

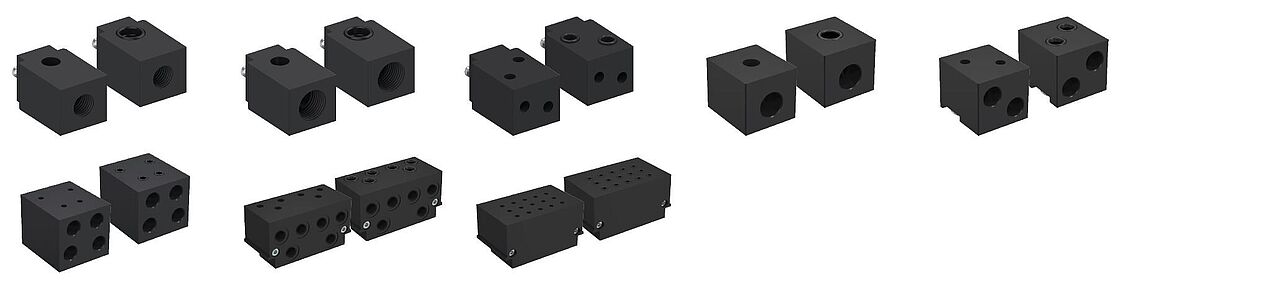

Energy elements

ENDLESS VARIETY

Energy elements are the most important accessories for tool changers and are essential for the transmission of a wide range of different media from the stationary part to the loose part. All tool changers offer integrated air transfer systems as standard. If larger or smaller cross-sections are needed, energy elements can be used. In addition, almost all media such as load current, signal current, hydraulics and communication can be transmitted using energy elements.

Our expertise—your advantage

- Standardized: Standardized interfaces and a modular design ensure flexible and cost-effective integration into all applications.

- Integration: Components can be integrated seamlessly into existing systems and processes.

- Innovative: The most modern technologies for efficient and future-proof solutions.