Connect. Weld. Innovate.

Metalworking for visionaries

#THEKNOWHOWFACTORY

Automation technology for metalworking

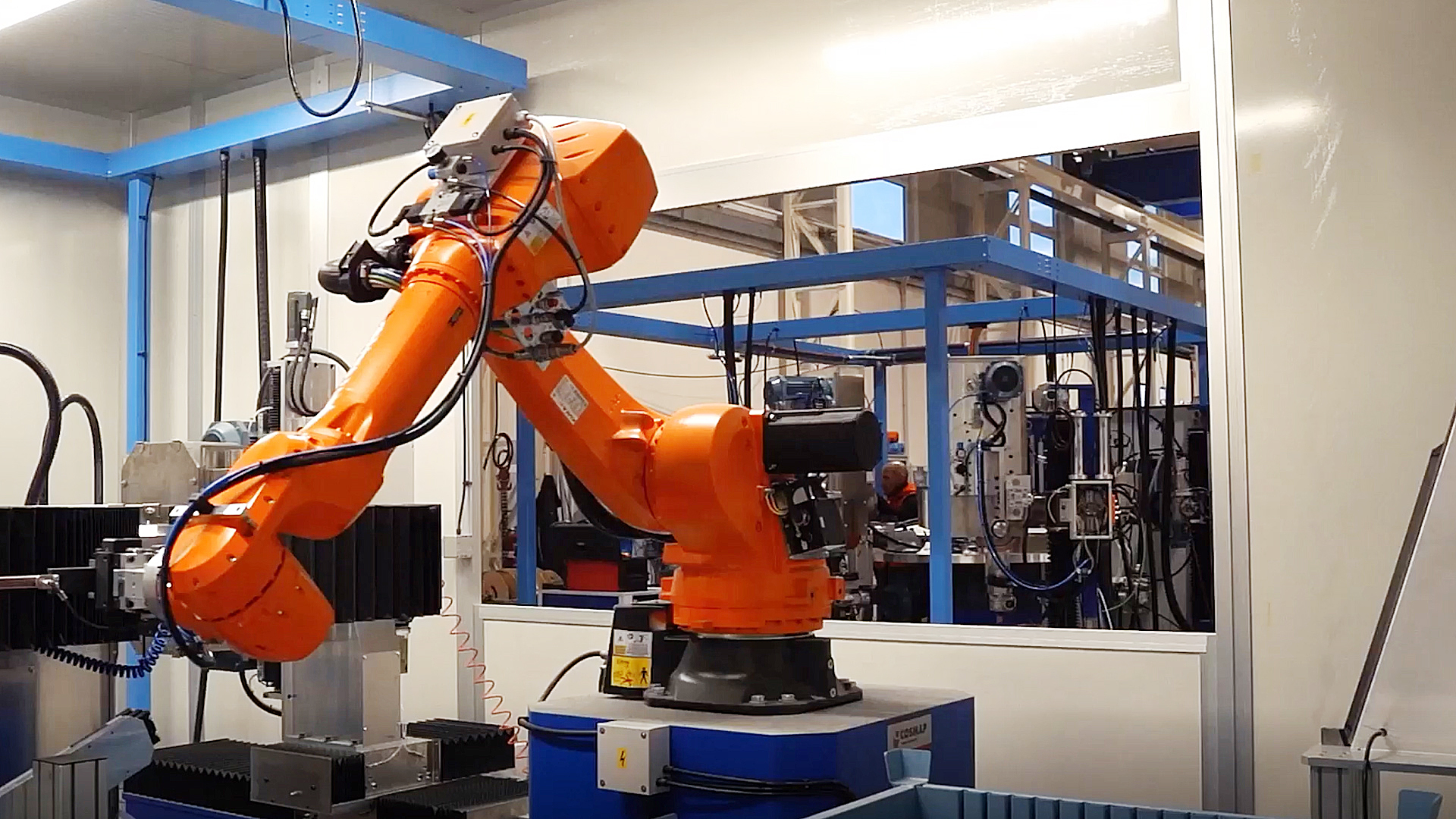

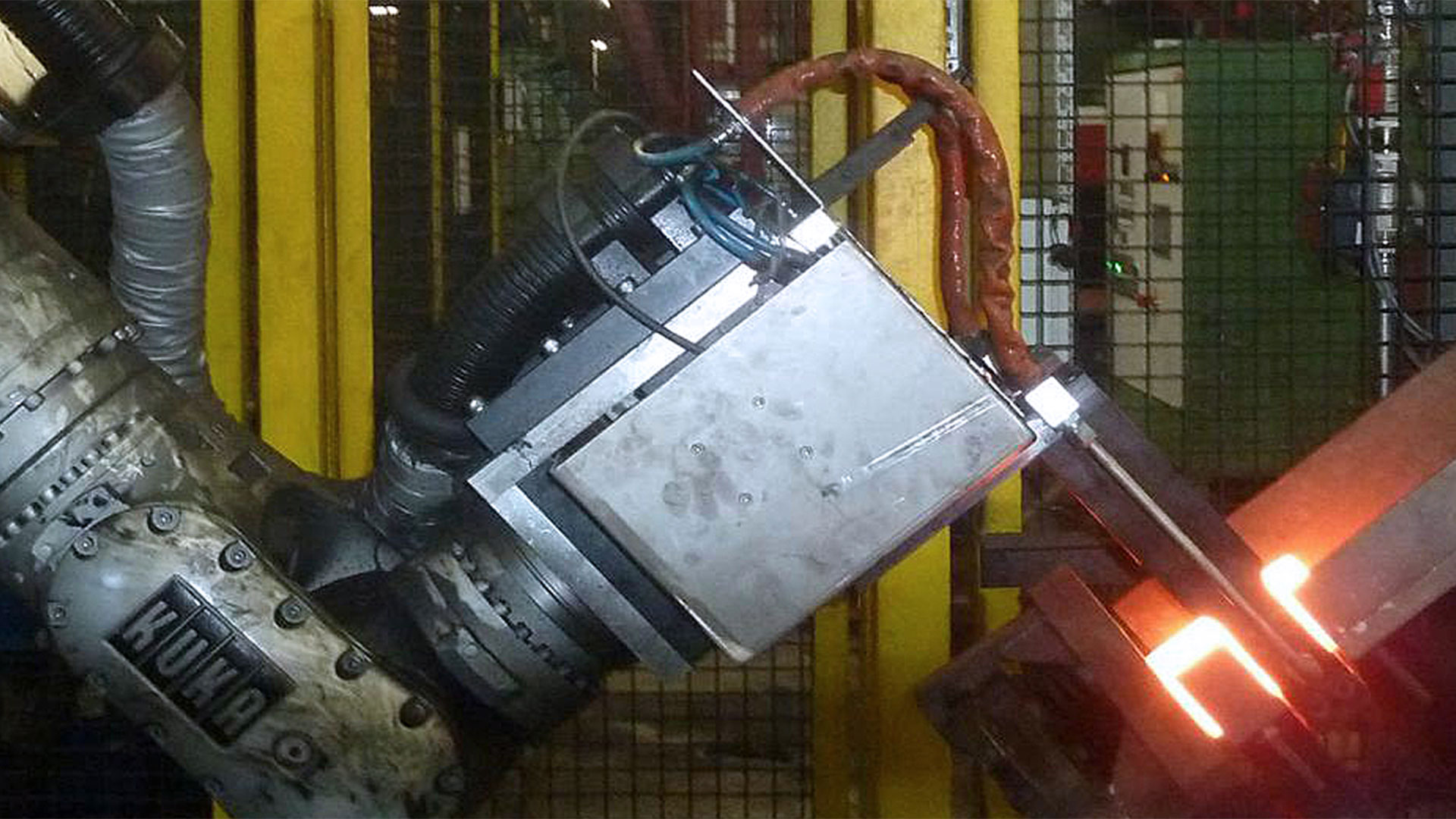

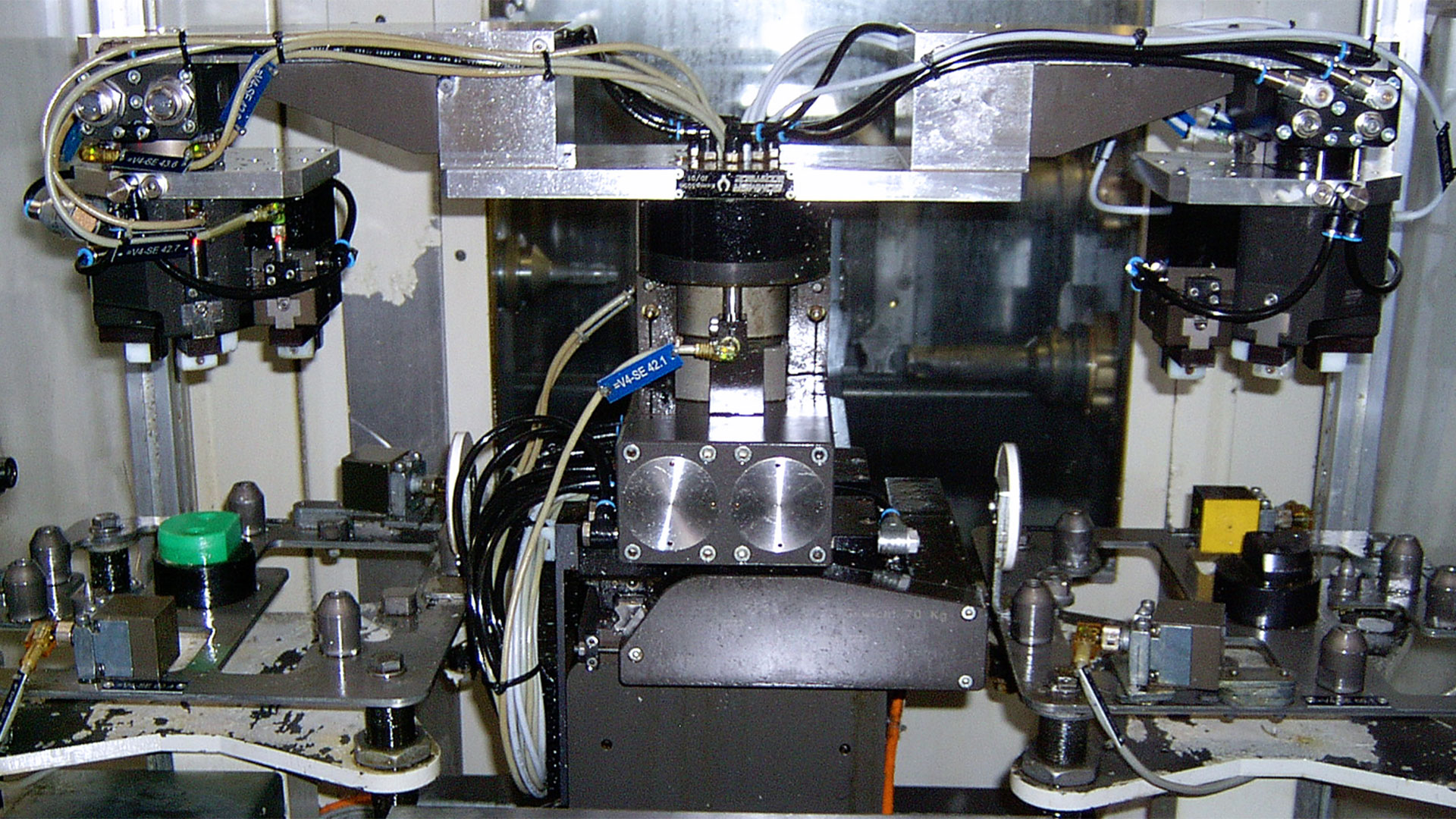

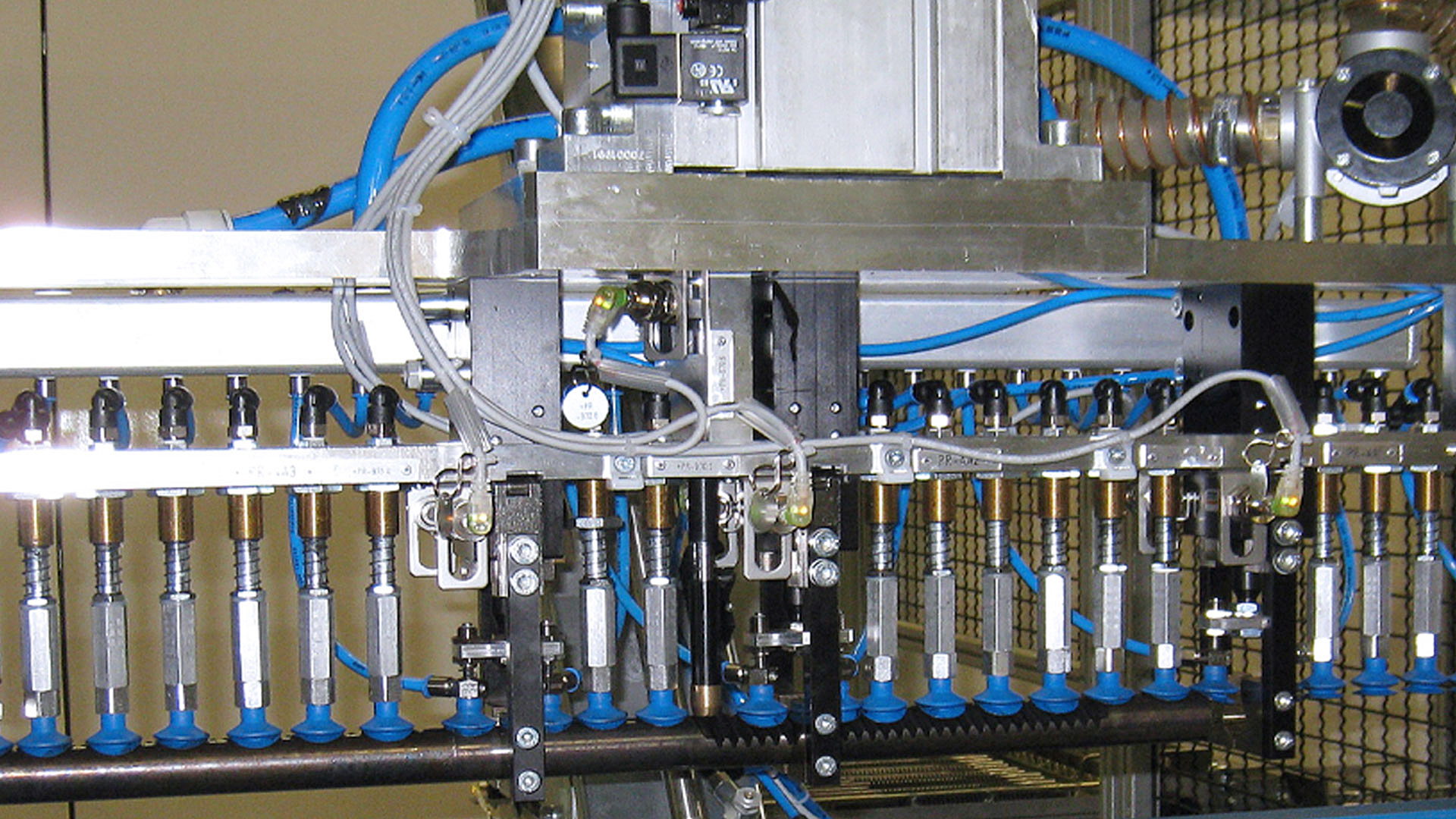

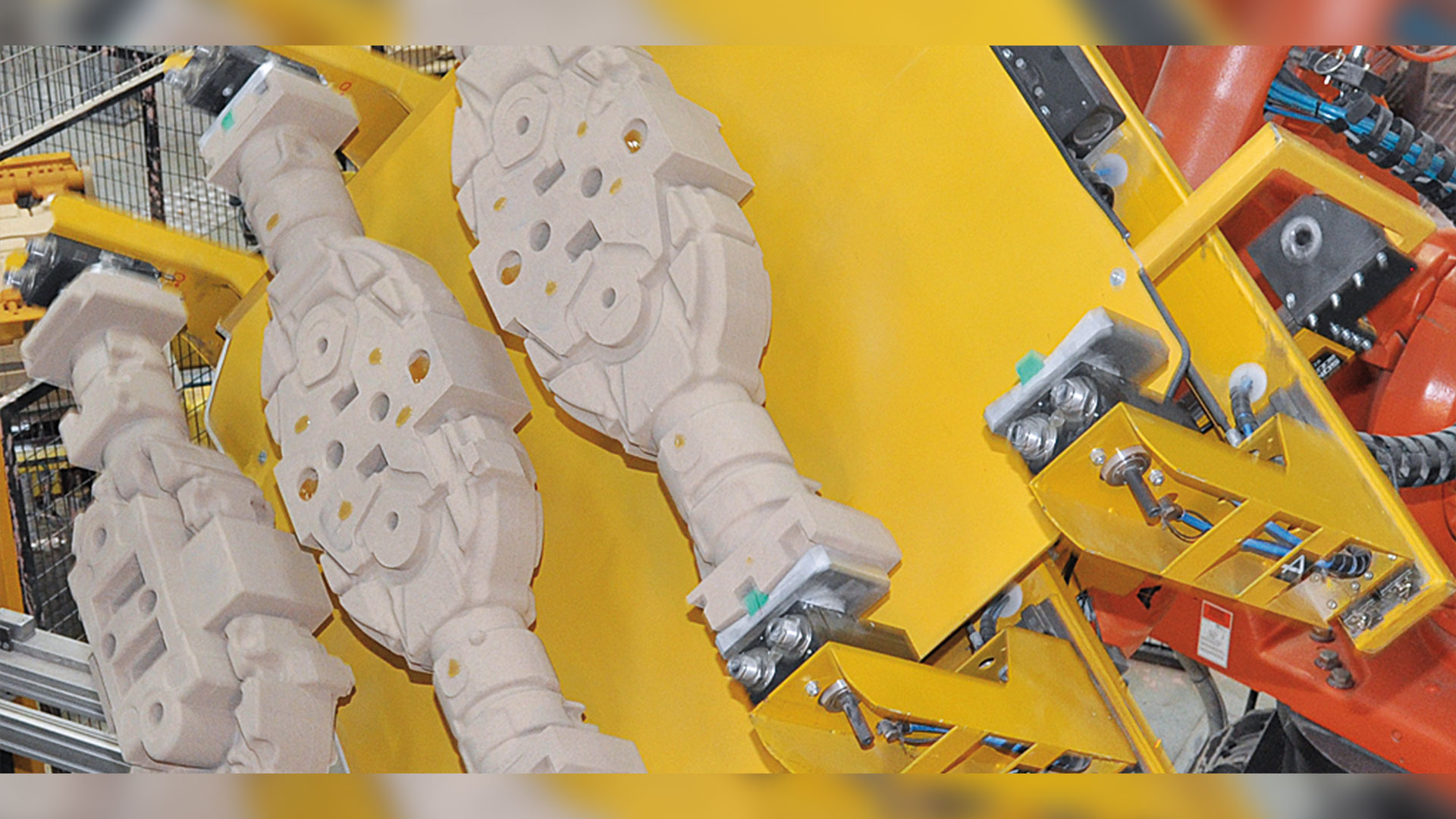

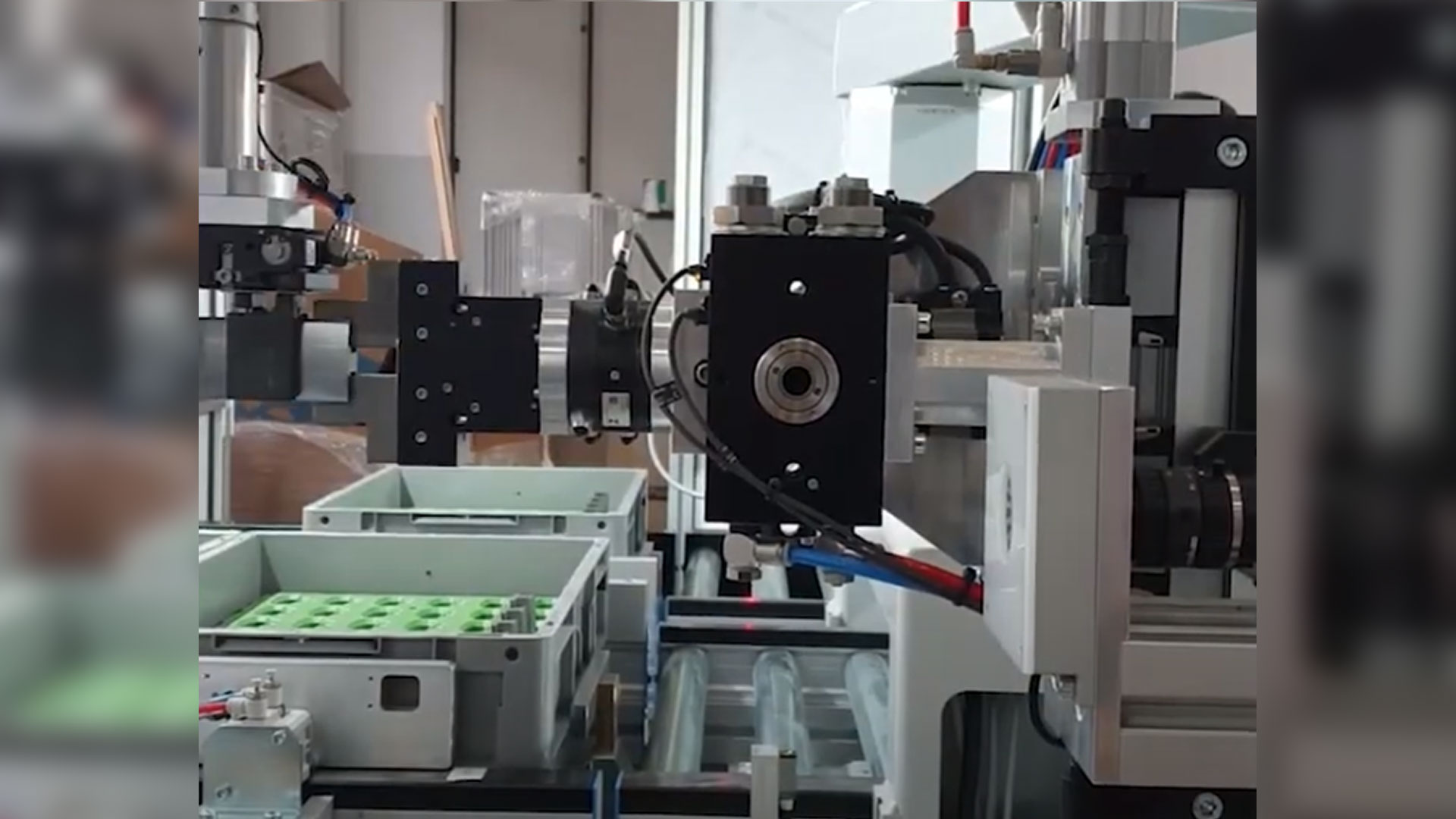

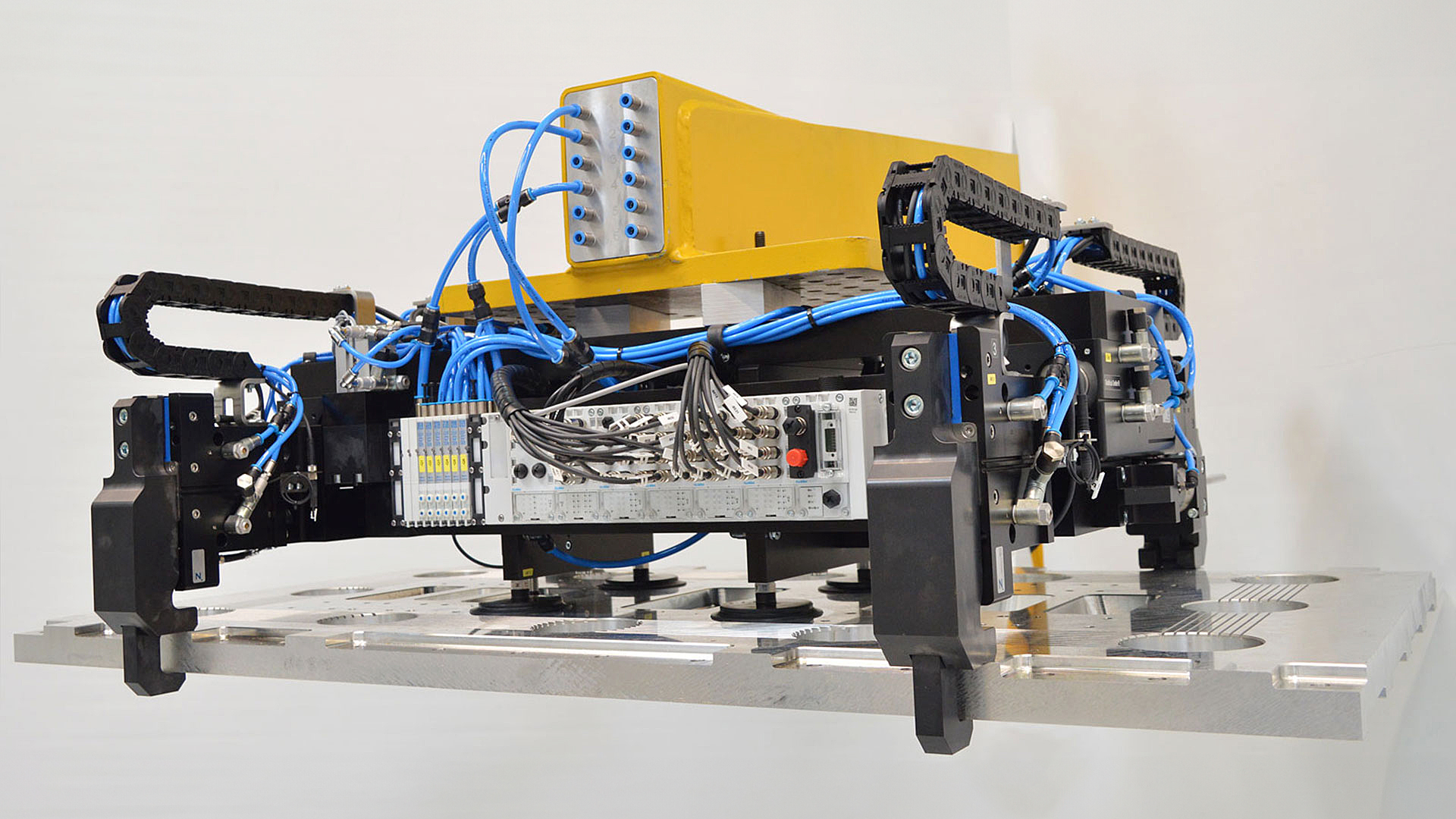

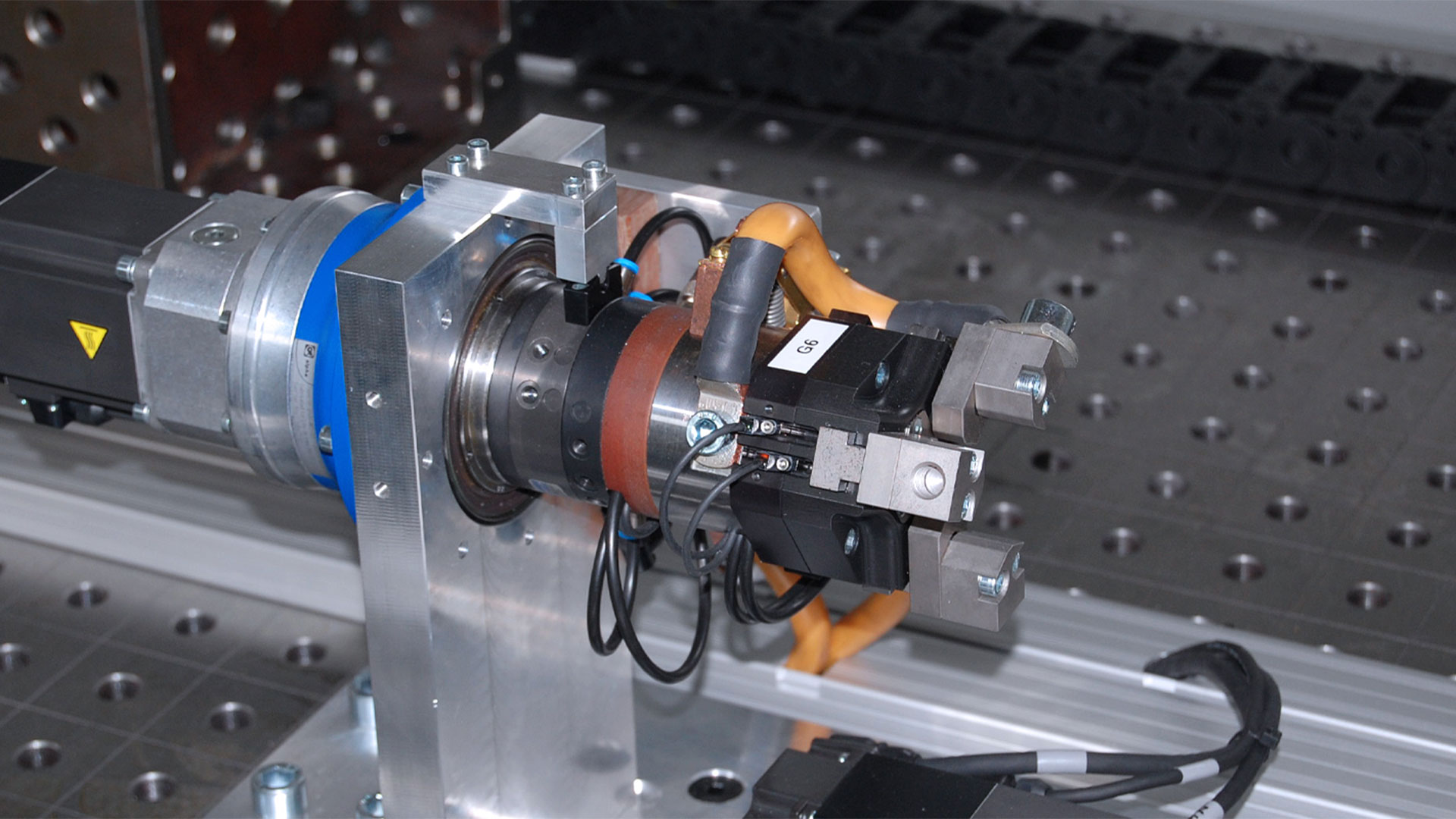

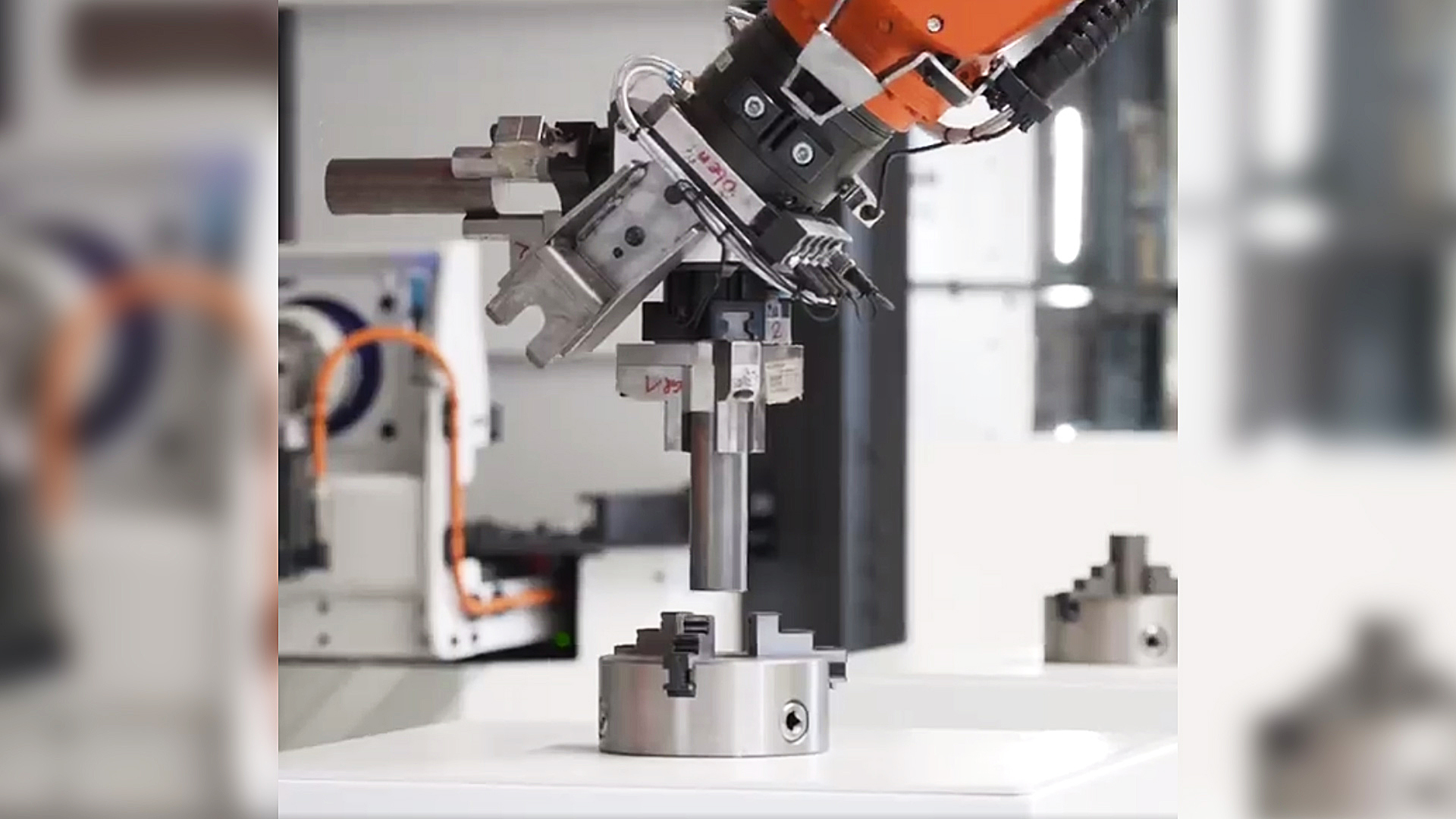

In metalworking, it is important to find the right balance between speed and precision. Our automation technology masters this challenge with flying colors. Intelligent components and system solutions integrate seamlessly into your existing production environment, increase process reliability and ensure consistent quality with every production batch. We understand the complexity of your trade and offer you customized handling systems and components from the fields of handling technology, robotics, industrial communication, clamping and braking technology, damping technology and mechanical engineering. These not only reduce production costs, but also ensure the flexibility and scalability of your production. With our expertise in the field of Industrie 4.0, we drive the digital transformation of your company – rely on technology that thrills today and sets new benchmarks for tomorrow!

Do you need support with your metalworking application? We look forward to your inquiry and will be happy to advise you!

Your benefits:

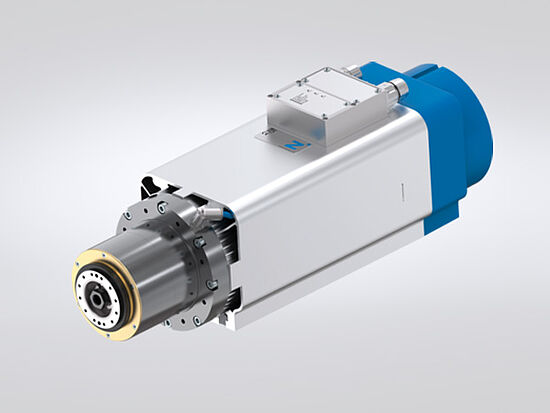

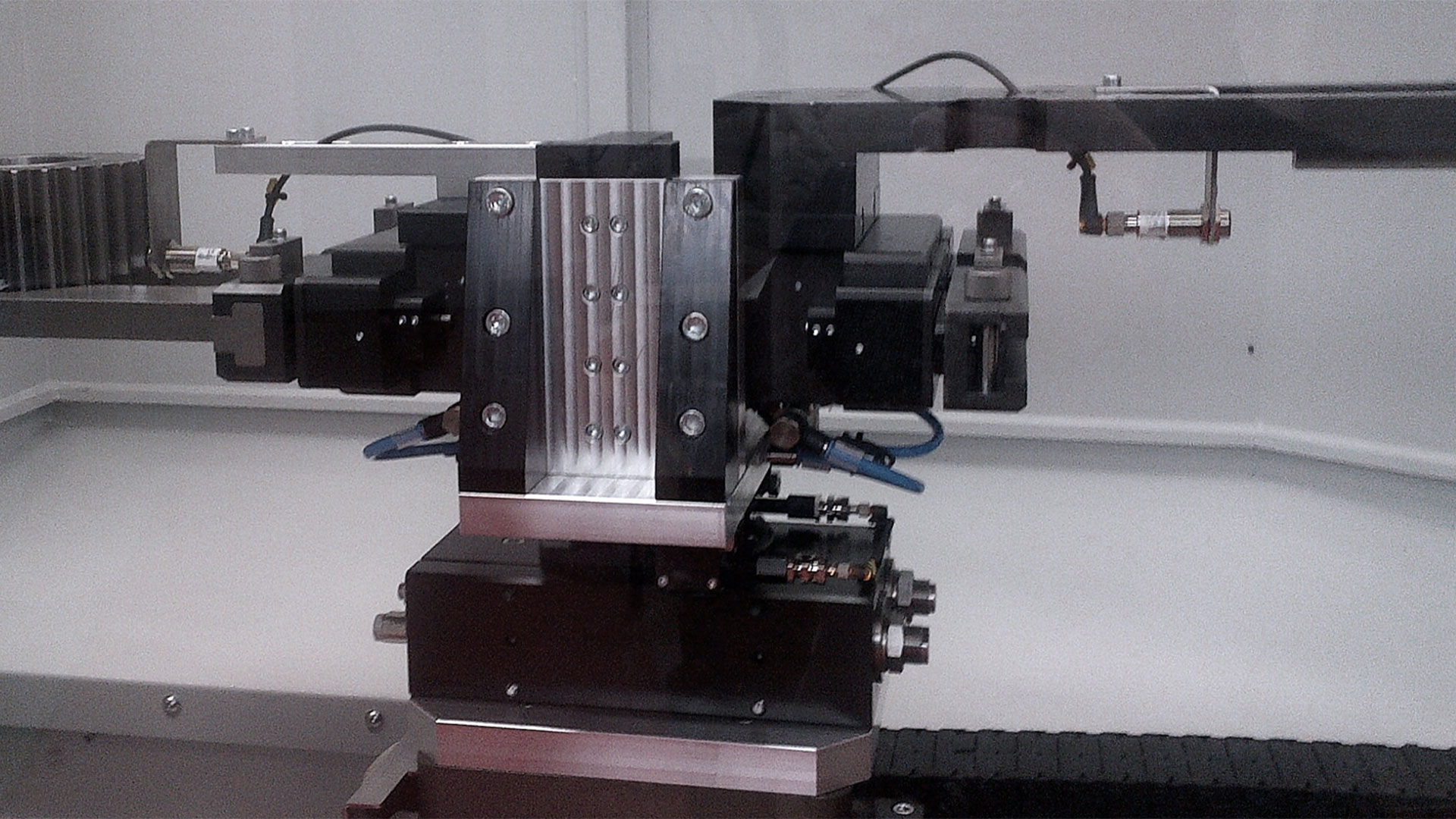

- Essential assemblies in tooling machines, milling centers or predestined for robot use

- Specially sealed products for use in the most adverse environmental conditions

- Compliance with proven safety principles for a safe working environment for the user and the machine

- 3D and rotary machining of workpiece and material

- Fluid- or water-cooled motor spindles for low and high performance range

- Wide range of modular construction systems in various performance classes and designs for machining

Broad product portfolio

The Zimmer Group offers a wide product range of individual components for manufacturers of machining centers, ranging from the motor spindle as a machining component to zero-point clamping systems and pallet changers for automation solutions through to clamping elements and shock absorbers to increase the performance of the machine.

Focus story: Maximum performance for metal processing

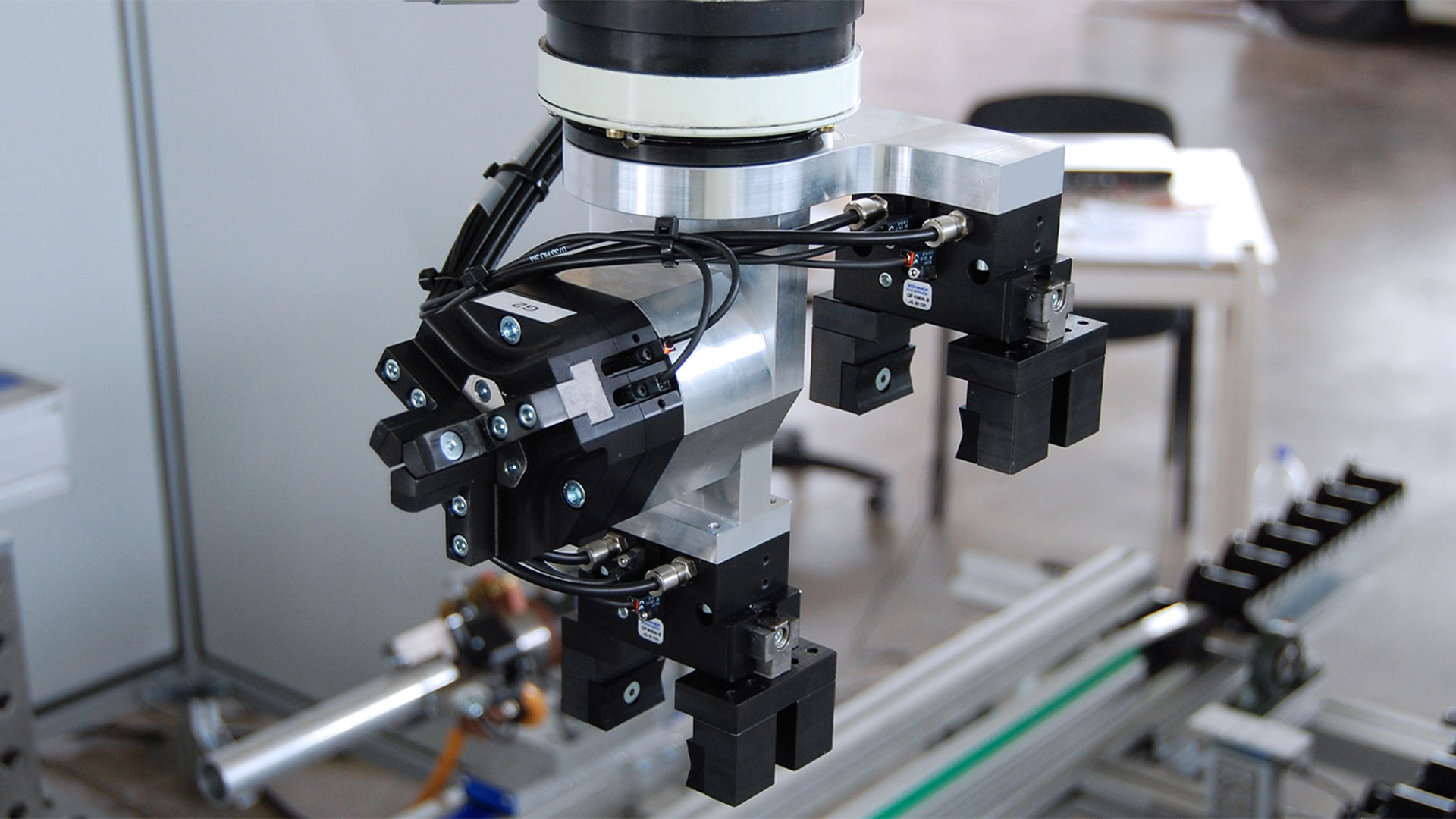

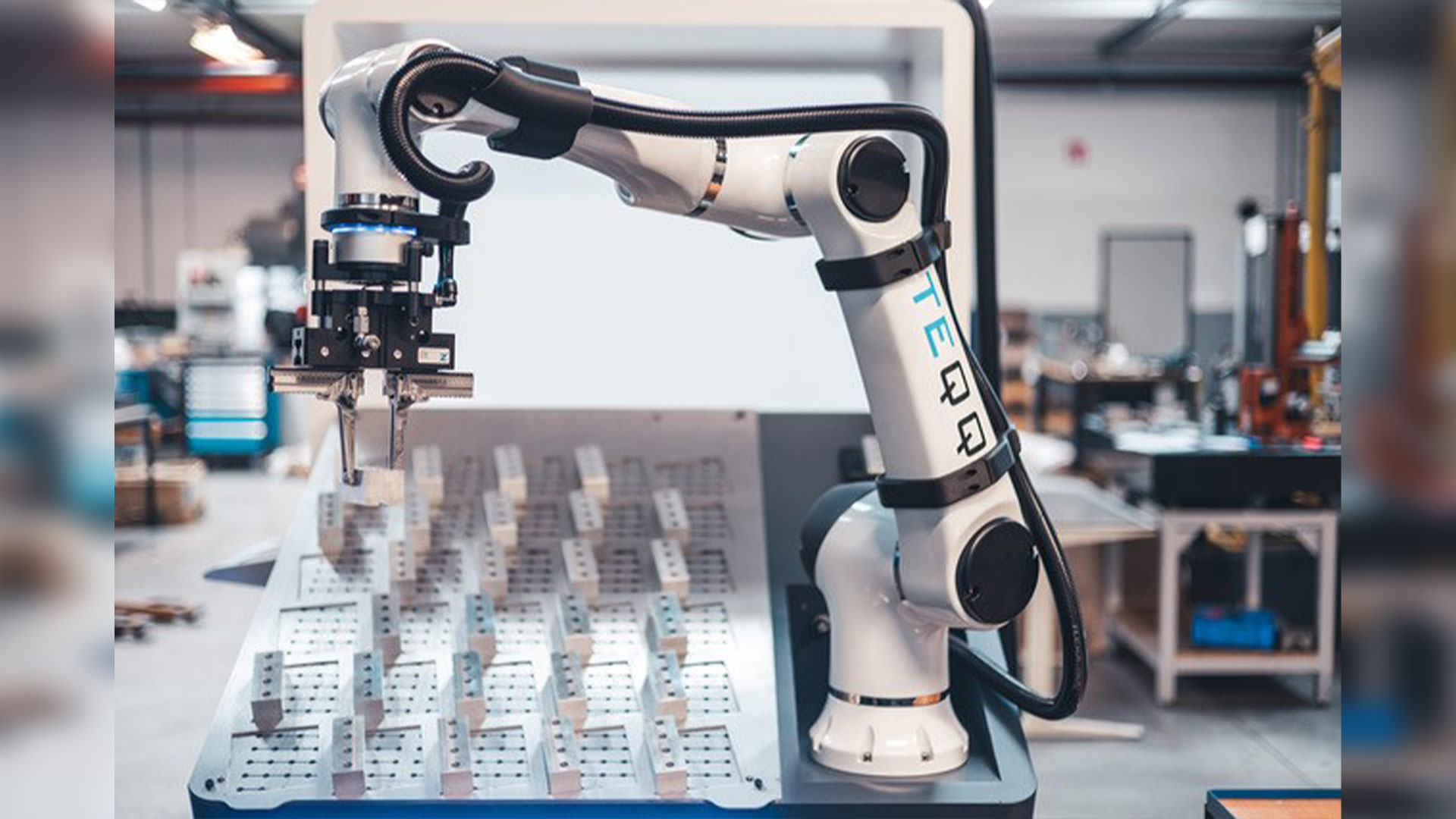

With their steel/steel guide, the grippers in the 5000 series feature lasting precision, robustness and durability with maintenance intervals of up to 30 million gripping cycles. Thanks to the sealed guides, the universal grippers achieve a degree of protection of up to IP67 and are therefore also suitable for use in dirty environments. The Dutch company TEQQ also relies on the proven end effectors for its cobots for metal processing.

Flat Swivel Units

Series SF-C

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

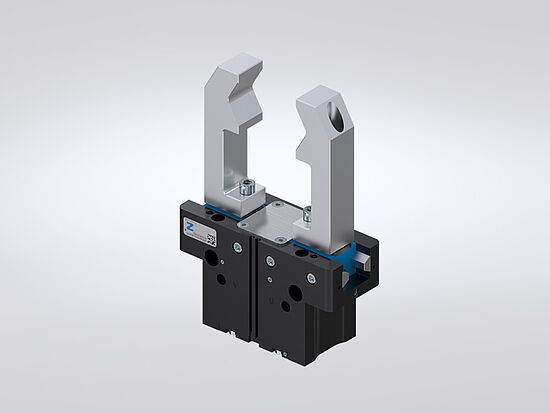

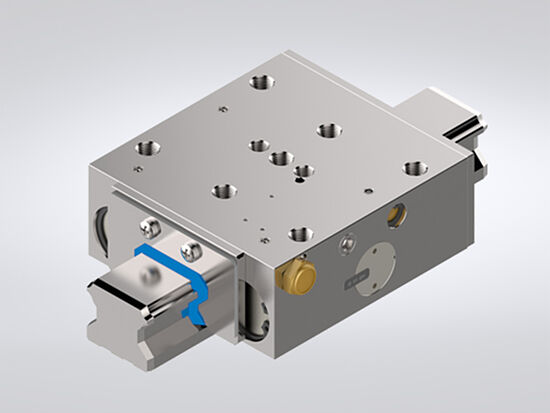

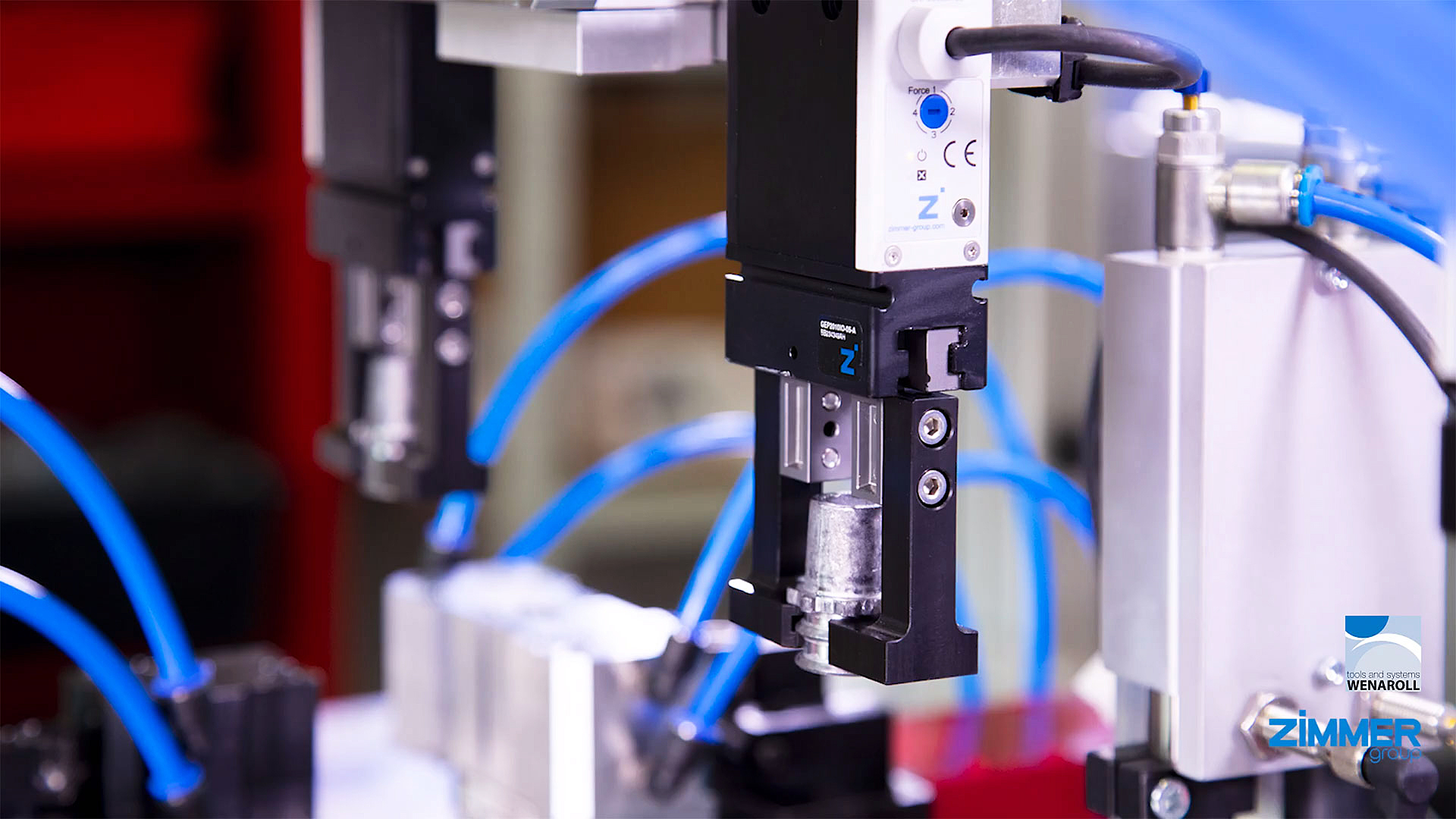

2-Jaw Parallel Grippers

Series GP400

- High gripping force as a result of optimal direction change of driving force into gripping force

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

- High gripping force as a result of optimal direction change of driving force into gripping force

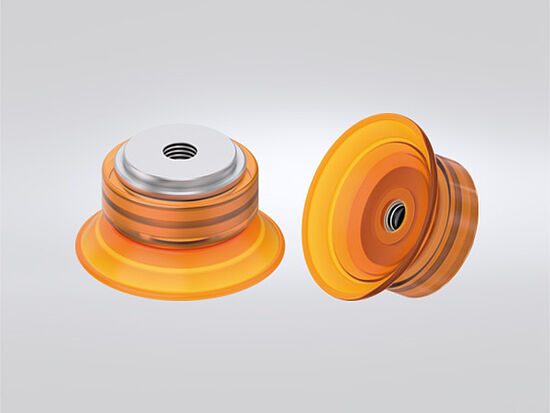

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

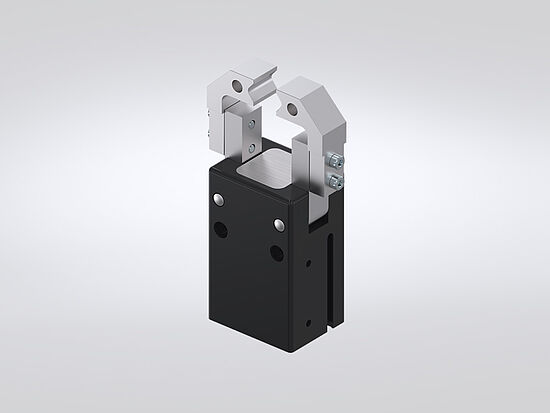

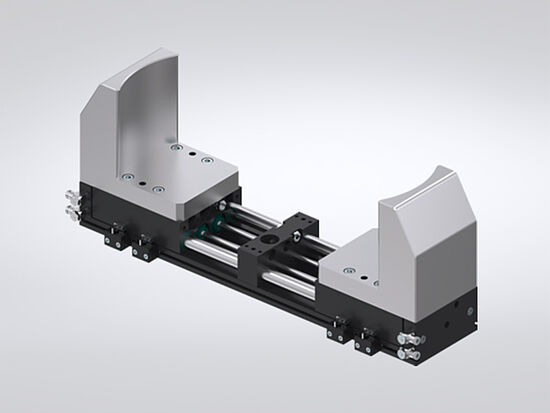

2-Jaw Parallel Grippers with Long Stroke

Series GH7000

- Heavy load linear guide for use under extreme conditions

- Ideal for highest transverse forces and moments capacity

- Heavy load linear guide for use under extreme conditions

- Ideal for highest transverse forces and moments capacity

Flat Swivel Units

Series SF-C

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

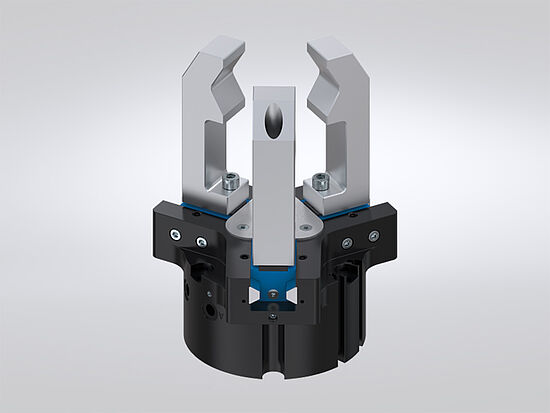

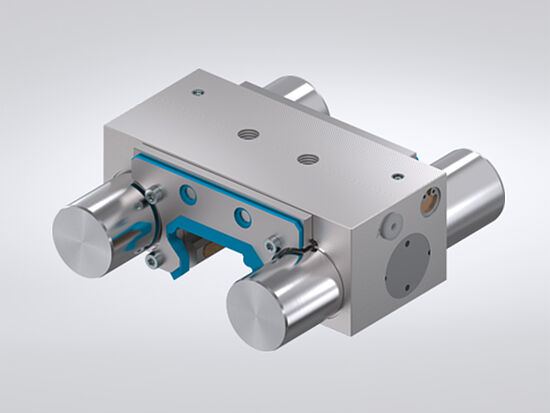

3-Jaw Concentric Grippers

Series GD300

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

2-Jaw Parallel Grippers

Series GP400

- High gripping force as a result of optimal direction change of driving force into gripping force

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

- High gripping force as a result of optimal direction change of driving force into gripping force

2-jaw radial gripper

Series GK

Flat Swivel Units

Series SF-C

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

3-Jaw Concentric Grippers

Series GD300

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

2-Jaw Parallel Grippers

Series GP400

- High gripping force as a result of optimal direction change of driving force into gripping force

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

- High gripping force as a result of optimal direction change of driving force into gripping force

2-Jaw Parallel Grippers

Series GP400

- High gripping force as a result of optimal direction change of driving force into gripping force

- High gripping force as a result of optimal direction change of driving force into gripping force

3-Jaw Concentric Grippers

Series GD300

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GEP2000

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

Flat Swivel Units

Series SF-C

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

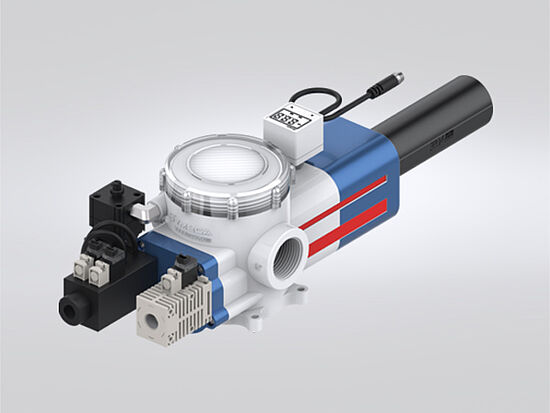

Rotary Distributors

Series DVR

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

2-Jaw Parallel Grippers with Long Stroke

Series GH6000

2-Jaw Parallel Grippers

Series GPP5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

3-Jaw Concentric Grippers

Series GPD5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

2-Jaw Parallel Grippers

Series GEP2000

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

- Robot flange with partial mounting circle in accordance with EN ISO 9409-1

- Very high handling weight up to 300 kg

3-Jaw Concentric Grippers

Series GD300

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

Rotary Distributors

Series DVR

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

Rotary Distributors

Series DVR

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

Angle flange

Series WFR

3-Jaw Concentric Grippers

Series GPD5000

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative

- Suitable for low to high loads

- Connection flange according to EN ISO 9409-1: TK40... TK160

- With 4...8 pneumatic feedthroughs

- With 4...12 electrical feedthroughs

- Steel Linear Guide – The superior guidance system concept

- Leakproof and corrosion protected – The universal gripper

- Aluminum Linear Guide – The alternative