TOP OF THE CLASS

TOP OF THE CLASS

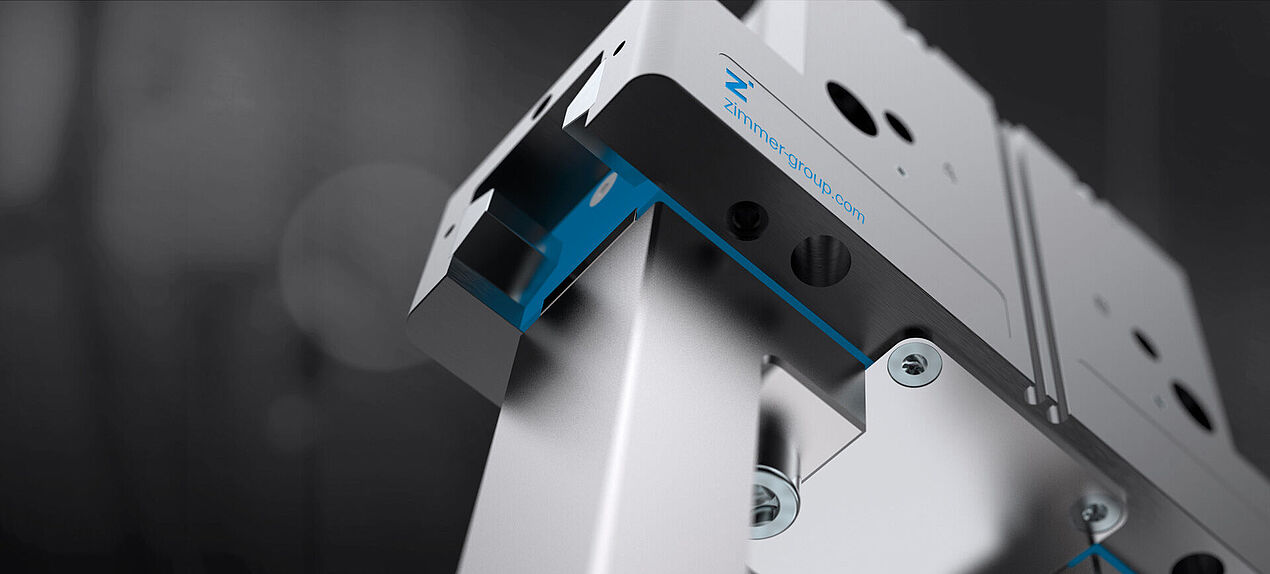

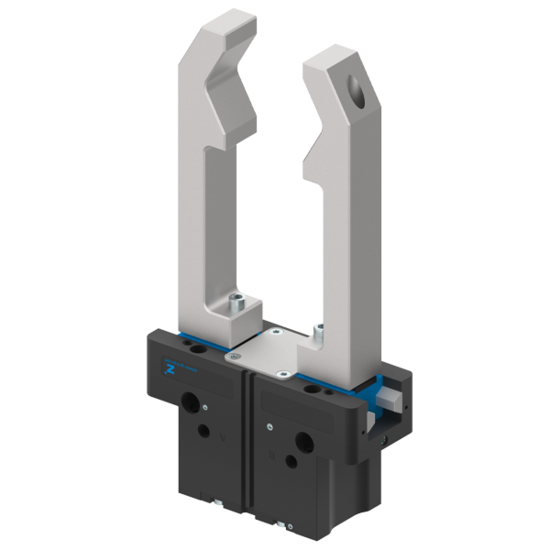

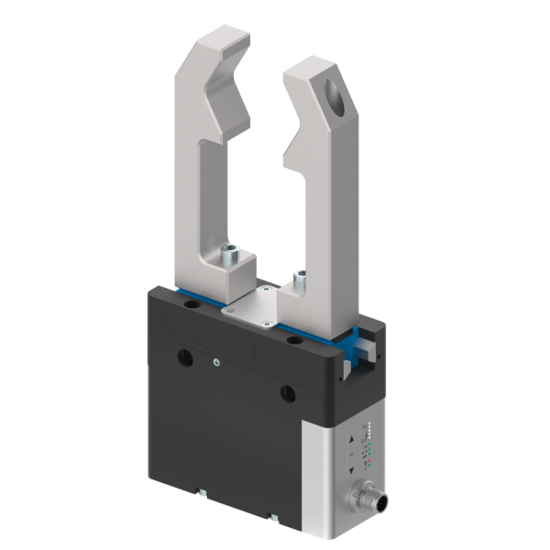

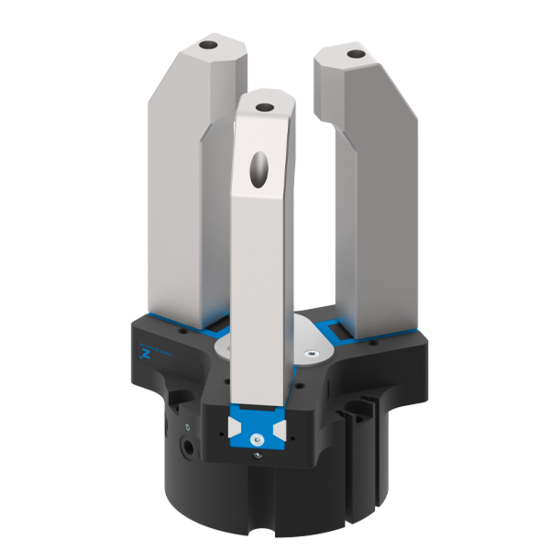

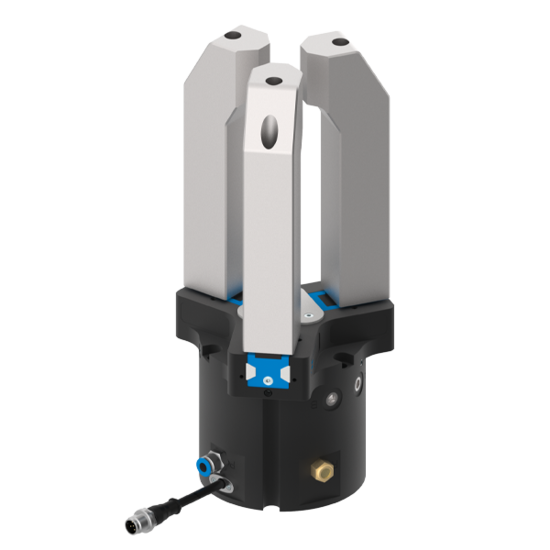

The multi-award-winning premium pneumatic grippers from the 5000 series with their extremely robust, hard-coated steel-in-steel profile groove guide can truly take on any role. Designed for genuine universal use, they have a range of features (speed, high gripping forces, long gripper jaw lengths) depending on the variant and therefore offer the right solution for every application!

YOUR BENEFITS

- Steel Linear Guide – our most process reliable and most precise guide

- Corrosion protected and sealed up to IP67 – for the toughest environment parameters

- Up to 30 million cycles with no maintenance required – worry-free production

- Pneumatic, pneumatically intelligent, electrical – flexible with three drive concepts

- One mounting drill pattern for three drive concepts – no engineering effort when replacing

SEALED TIGHT – DESPITE ANY CHALLENGES

All premium grippers in the 5000 series are corrosion-protected and sealed to IP64 as standard, i.e. they are dust-tight and protected against spray water from all sides. If a protector is used, they even have a tightness class of IP67 (dust-tight and protection against temporary submersion).

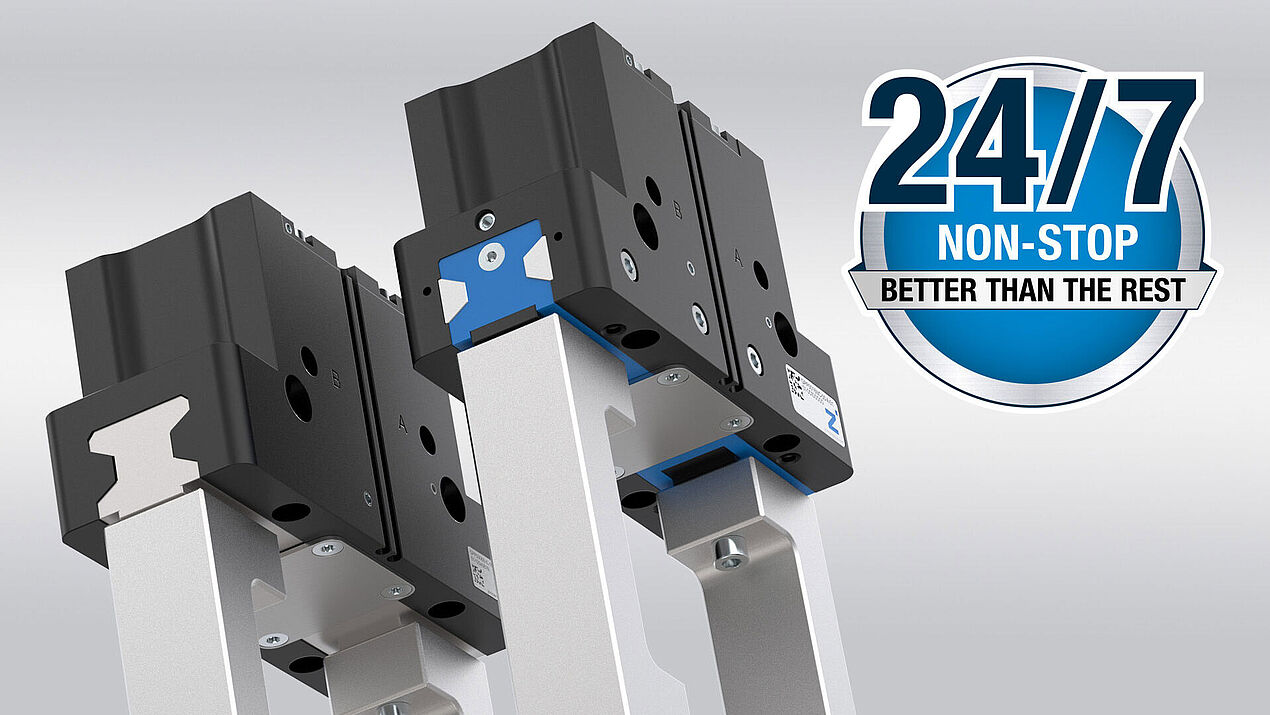

ENDURANCE CHAMPIONS

Thanks to their low friction coefficients, compact structure and excellent emergency running properties, the grippers of the 5000 series can handle at least 30 million cycles without maintenance.

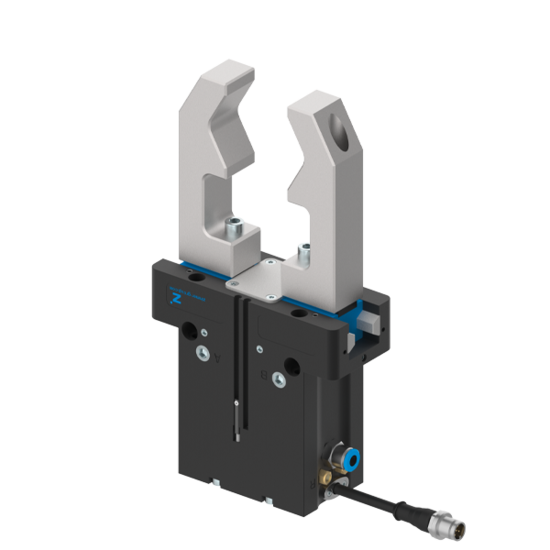

EQUIPPED FOR THE FUTURE

Are you Industrie 4.0-ready and looking for the right gripper? Then we recommend our -IL variant from the 5000 series. These pneumatic-electric IO-Link hybrid grippers are ideal for users who are taking the step into the Industrie 4.0 world of gripping but do not want to do without a pneumatic drive. A sensor system is integrated into the gripper that detects the position of the gripper jaws in the range of +- 0.05 millimeters. This not only enables process monitoring, but also, for example, the identification of workpieces based on their diameter. In addition, a total of 32 workpiece data records can be programmed into the grippers.

You can find out how to integrate the IO-Link gripper into your PLC environment step-by-step here:

THE CHOICE IS YOURS

In addition to our grippers with a steel-in-steel profile groove guide (Steel Linear Guide), you also have the option of choosing a model with a steel-aluminum profile groove guide (Aluminum Linear Guide). These grippers are particularly interesting for price-conscious customers who do not want to do without the proven quality of the Zimmer Group. Technically, the GPP/GPD5000AL grippers with their steel-aluminum profile groove guide outperform all T-slot grippers and are at least on a par with grippers with multi-tooth guides in the market environment. With its uncompromising “Made in Germany” quality, the Zimmer Group guarantees up to 15 million cycles without maintenance.

BENCHMARK – REAL DIFFERENCES

Products

Accessories

The 5000 series grippers feature a variety of detailed solutions that make everyday use easier. In addition, we offer a wide range of gripper accessories such as universal, adjusting or interchangeable jaws as well as pressure pieces that greatly reduce the loads on grippers that occur during the joining process, for example.

SYSTEMS

In addition to our standard gripper components, we also offer customized system solutions – from specification to implementation – to meet your specific requirements. By using our proven modules, we specialize in offering high-quality solutions at competitive prices. We offer ready-to-connect system solutions for your applications and have a wide variety of modules in our portfolio. These are very easy to adjust and configure and can be conveniently adapted to your particular application. Our proven system solutions, of which more than 9,000 are already in use on the global market, have a long service life with minimal maintenance requirements and are also Industrie 4.0-capable!