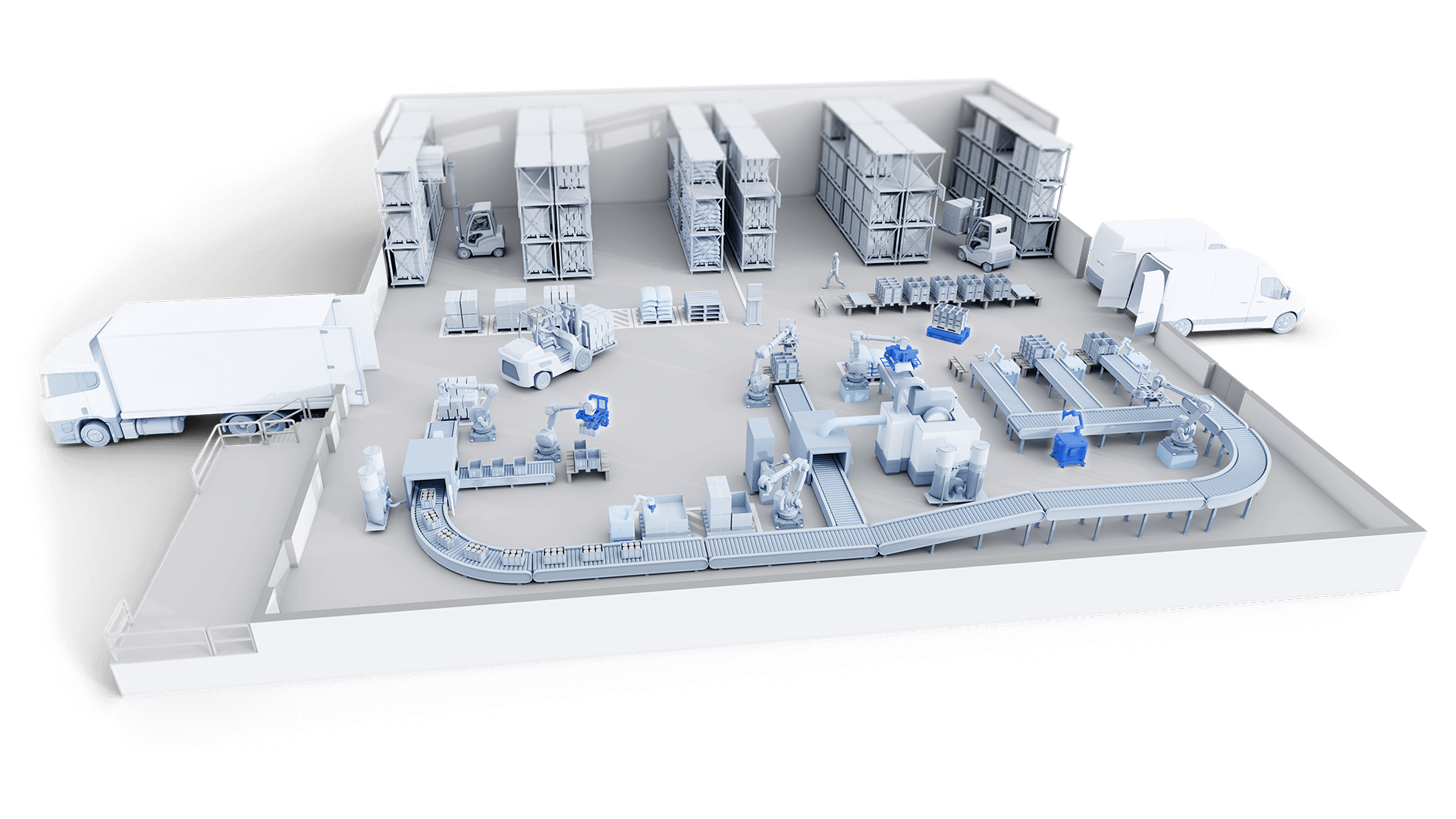

AUTOMATION SOLUTIONS FOR YOUR INTRALOGISTICS

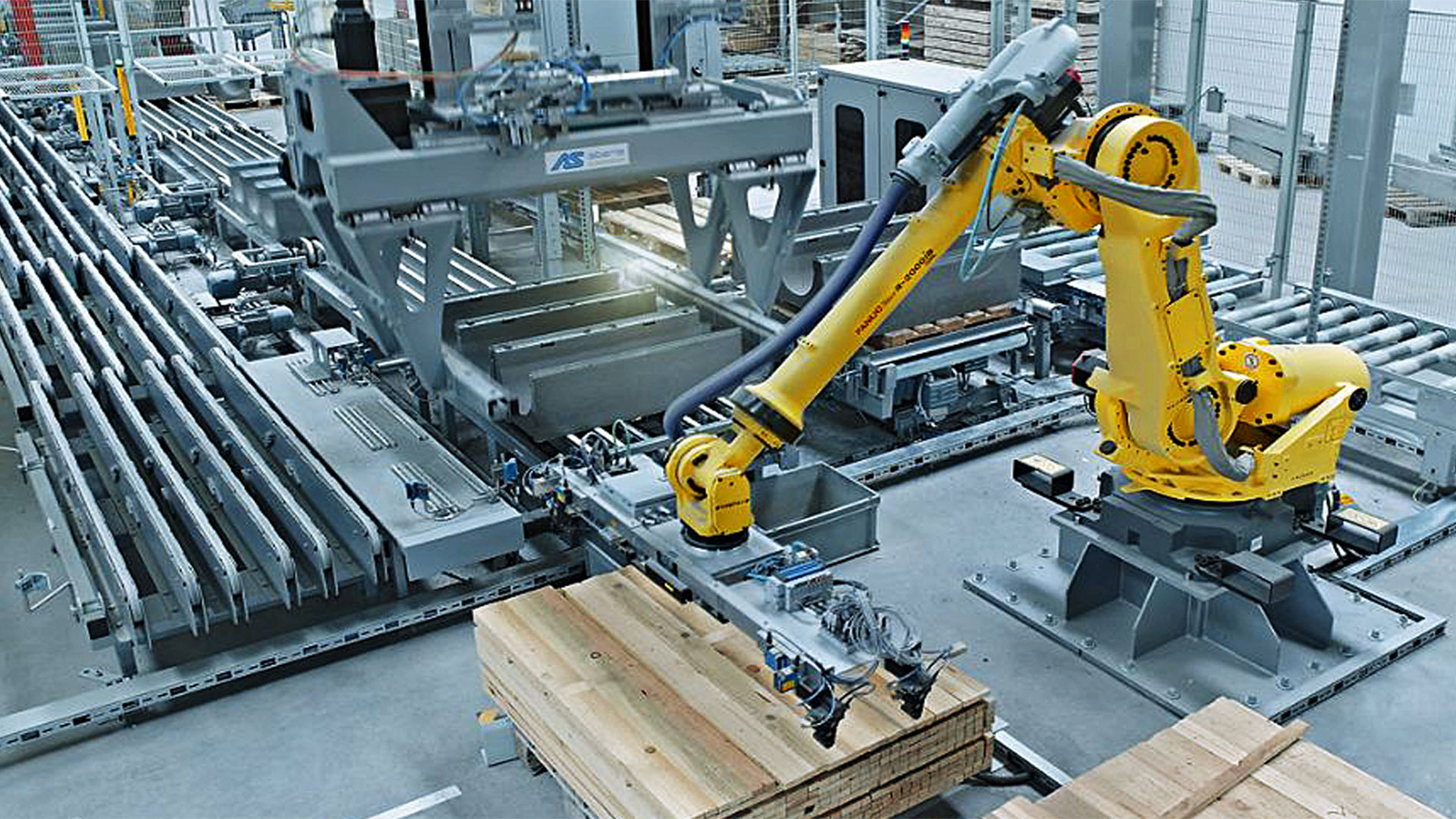

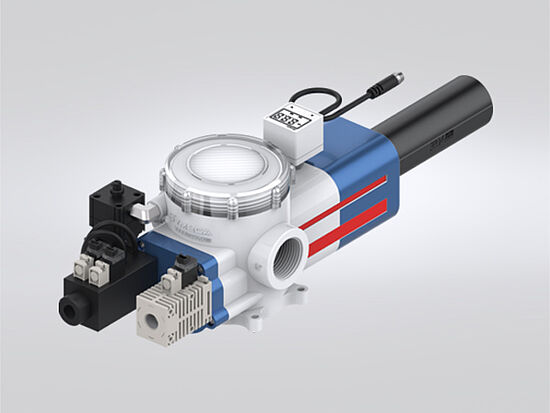

In a constantly changing world, companies are faced with the challenge of optimizing their intralogistics processes in order to increase efficiency and lower costs. With increasing competitive pressure and the growing demand for fast and error-free delivery, automation is no longer just an option – it’s a necessity. The Zimmer Group understands these challenges and offers customized automation solutions – from specialized gripper systems to flexible mobile robotics – to future-proof your business. Our innovative approaches ensure smooth integration into your existing processes and give you a real competitive advantage.

Are you ready to take your intralogistics to the next level? Contact us and find out how we can revolutionize your logistics processes together.

Your benefits:

- Economical and efficient processes

- Flexible automation solutions with short adaptation times

- Modular systems optimally tailored to your application

- Comprehensive system landscape

- Guaranteed long service life for maximum capacity utilization

- Tailor-made software solution for barrier-free integration

- Energy-efficient in the manufacturing and use of our products

Intralogistics with foresight

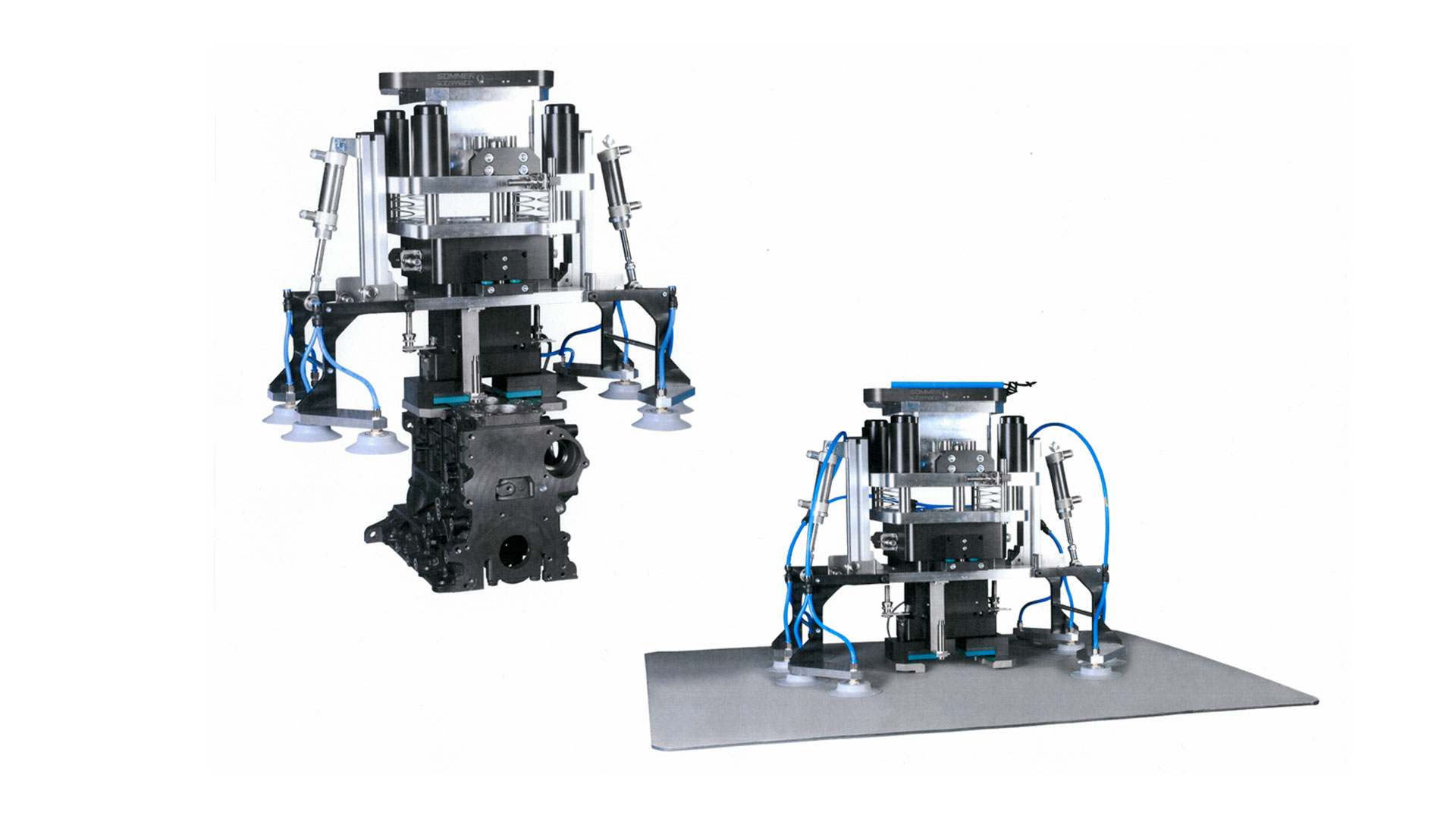

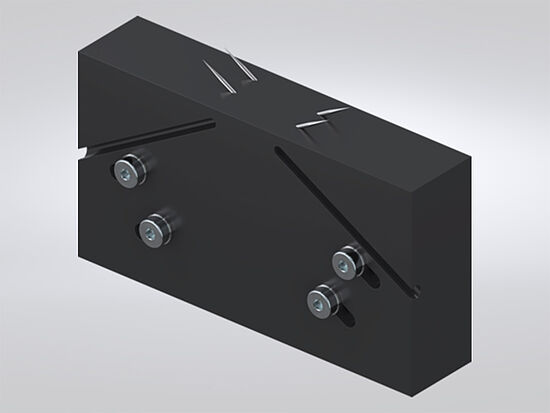

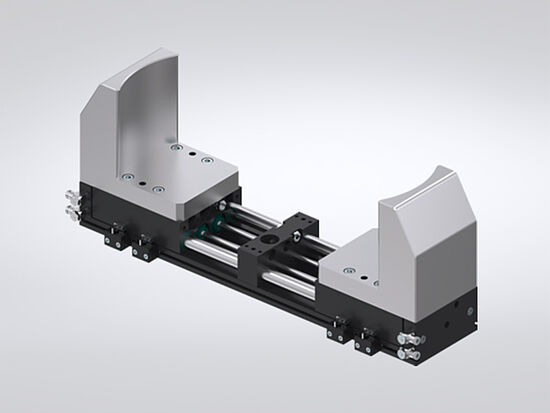

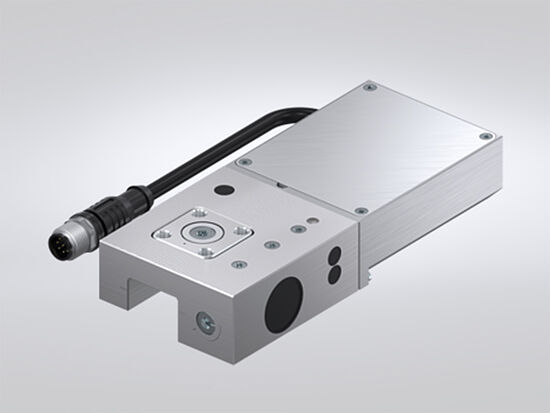

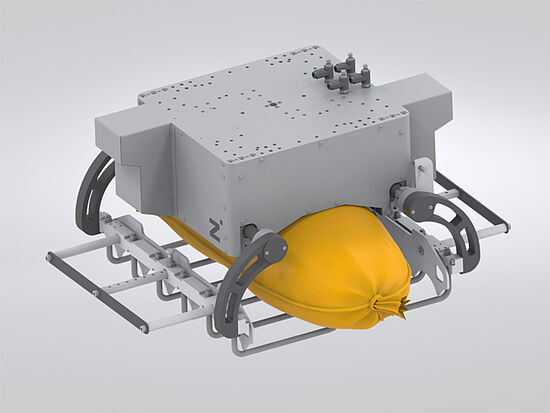

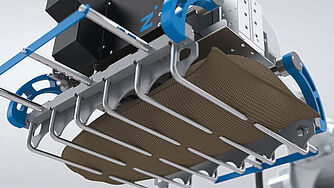

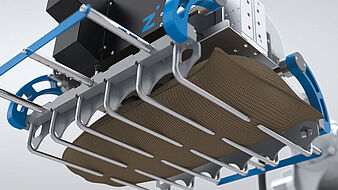

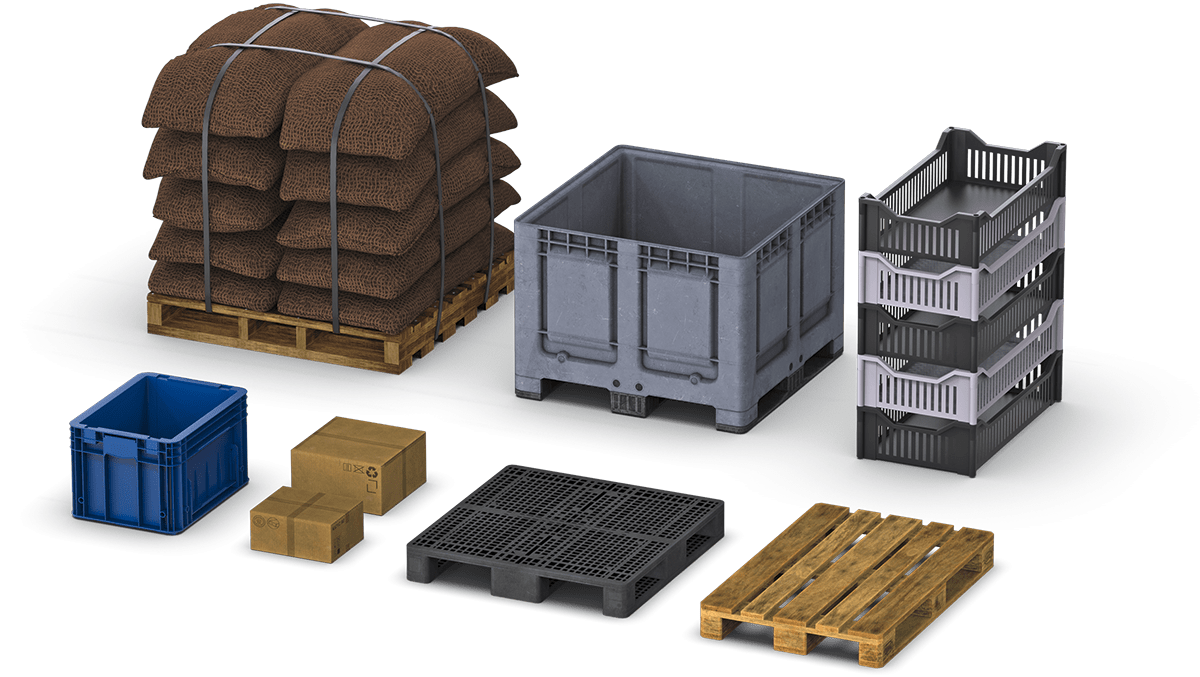

From rigid small load carriers to bags made of different materials – when it comes to automating intralogistics, companies are often faced with the challenge of finding the right handling solution for a wide variety of goods. Our wide-ranging portfolio of flexible grippers and adaptable modular construction systems guarantees universal yet customized solutions for almost any handling task. With our expertise and our comprehensive range of products, we enable seamless adaptation to your changing product range and thus advance your intralogistics in a future-oriented manner. Let us optimize your material flow processes together and revolutionize your logistics performance. We would be happy to advise you!