Zero-point clamping system

A zero-point clamping system is an innovative solution in workpiece clamping technology. It enables extremely fast and extremely precise retooling of workpieces, clamping devices or fixtures on modern processing machines.

Exactly the right system for your production

With the modular Zimmer Group zero-point clamping system, you will find the right system for every requirement.

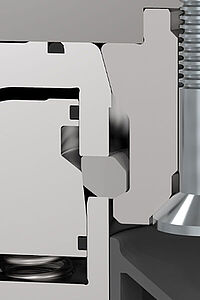

In addition to a standard version reduced to the basic functions, which fulfills the basic functions such as unlocking and PLUS connection, an advanced version with an extensive range of functions is also available, as required in automated production, for example. Both variants lock positively via clamp segments specially adapted to the bolt contour, creating an extremely rigid system that is able to absorb the highest forces with maximum repeat accuracy. The product range is supplemented by a wide variety of clamping plates, which are available in all sizes and different configurations. To increase the protection of the individual zero-point clamping system and prevent any ingress of dirt, there is an optional automatic lock that reliably protects the pin from opening.

For more information, please see our catalog.

Advantages

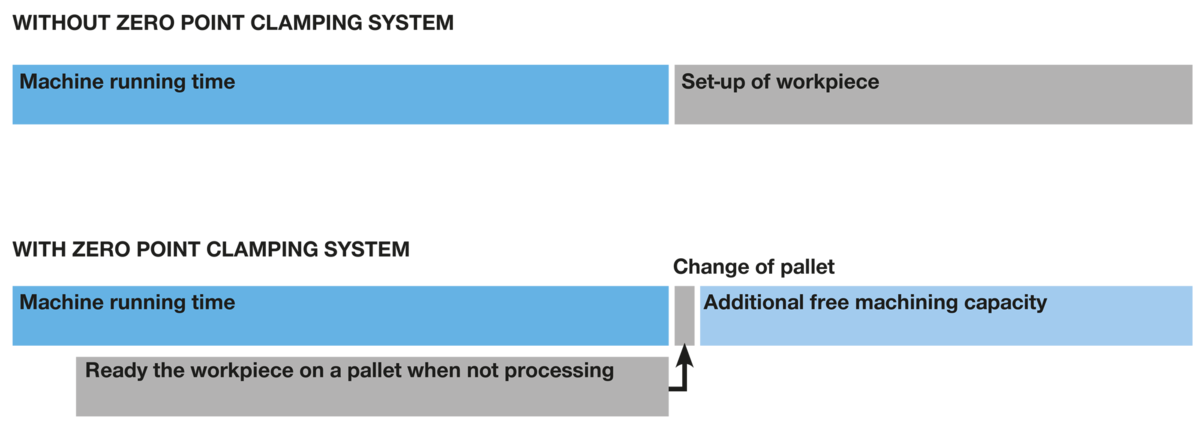

Increased productivity

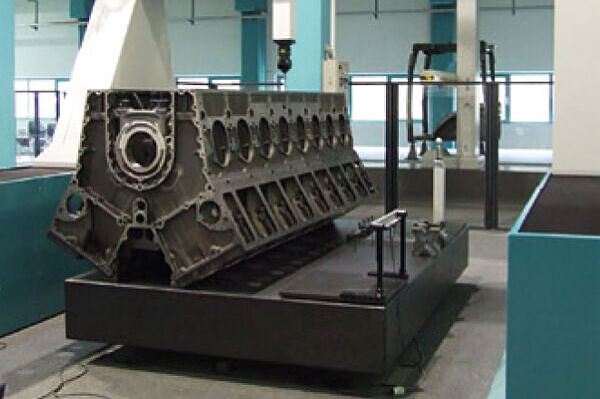

By automating the processes, the zero-point clamping system drastically increases productivity with the required precision. Machine set-up times are reduced by up to 90% and the cleaning and maintenance requirements of the system are minimal. The option of linking several consecutive processes in one workpiece clamping in different machining cells and equipping them with identical clamping system geometries results in previously unused synergy effects. The component carrier with the zero-point clamping system accompanies the production part a long way through the machining process, ensuring optimum precision and cost-effectiveness.

Maximum repeat accuracy and precision

Thanks to its sophisticated design, the zero-point clamping system achieves a repeat accuracy of 0.005 mm. Thanks to its very high pull-in forces and the consistent use of hardened stainless steel, the system offers a high-precision, torsion-resistant basis and additionally stabilizes components that tend to vibrate.

Increased process reliability

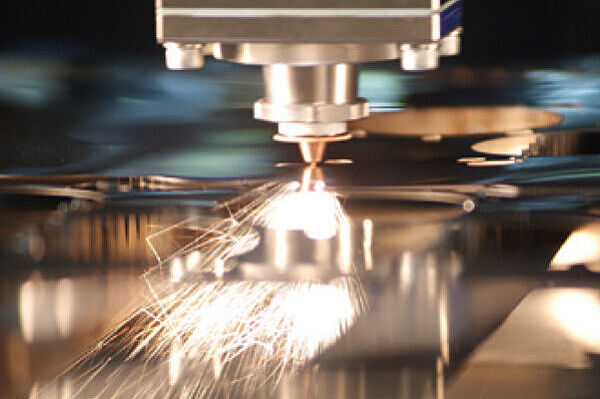

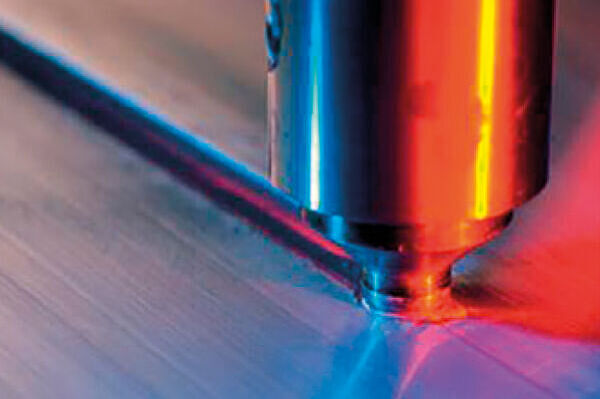

The zero-point clamping system reduces errors during milling, turning, wire or die eroding EDM, surface or cylindrical grinding, drilling, lasering and measuring. The maintenance-free design also contributes to superior process reliability.

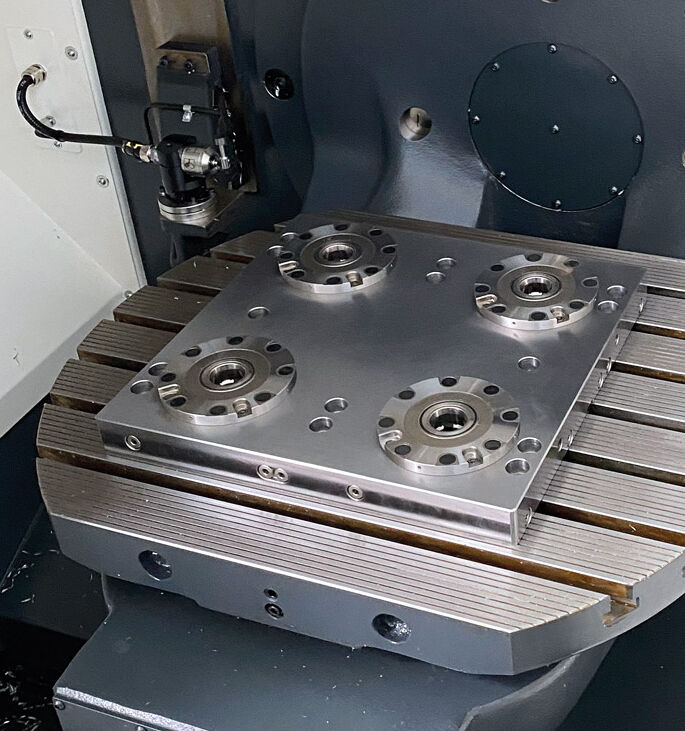

APPLICATION EXAMPLES