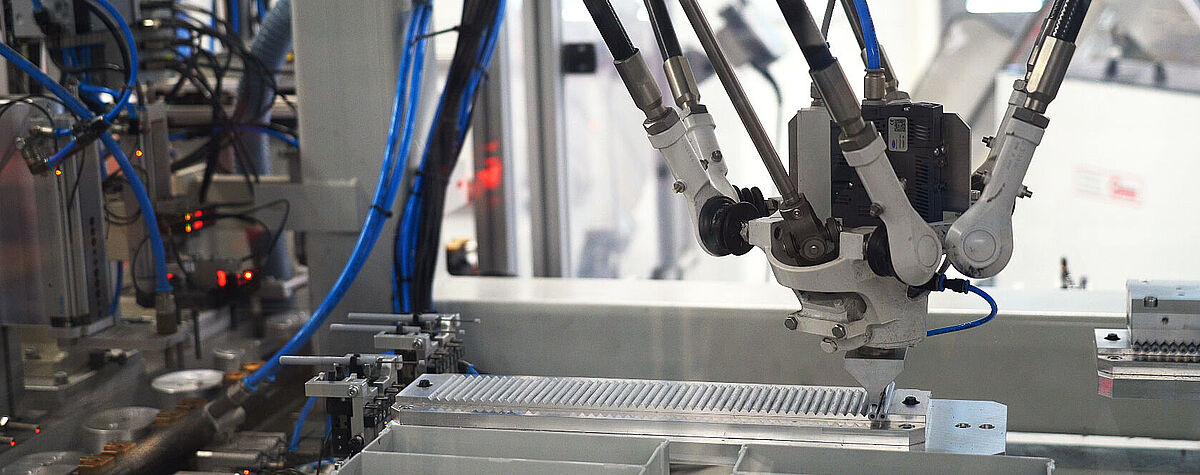

Robotics in industry

Requirements for industrial robotics and automation technology

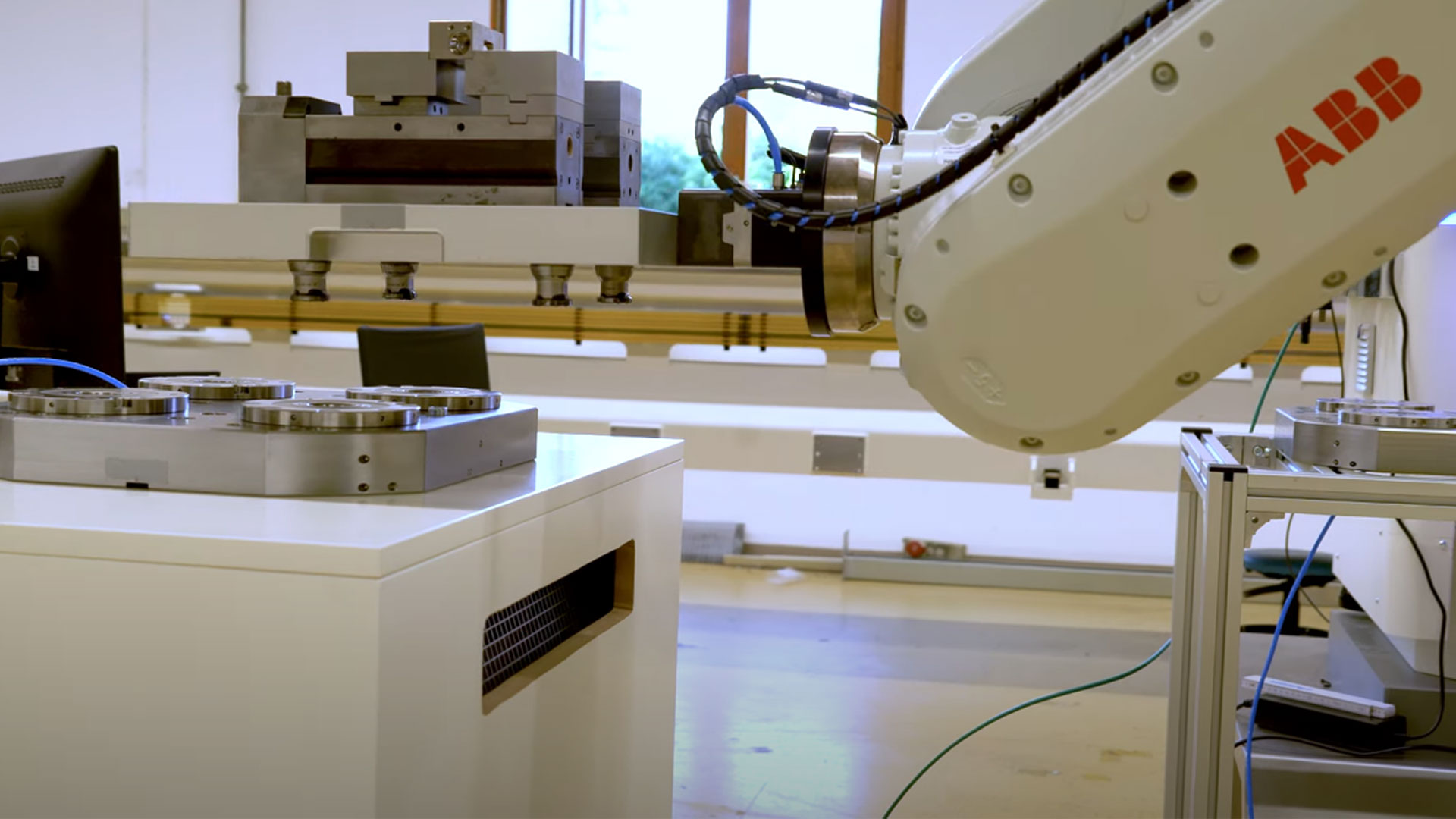

During its 40-year history, the Zimmer Group has evolved from a manufacturer of single components to become a full-range supplier and provider of complex system solutions in the field of robotics. With the exception of the robot itself, the portfolio covers the entire spectrum for industrial robotics, including lightweight robotics – from high-functioning grippers to robot accessories (e.g., crash protection).

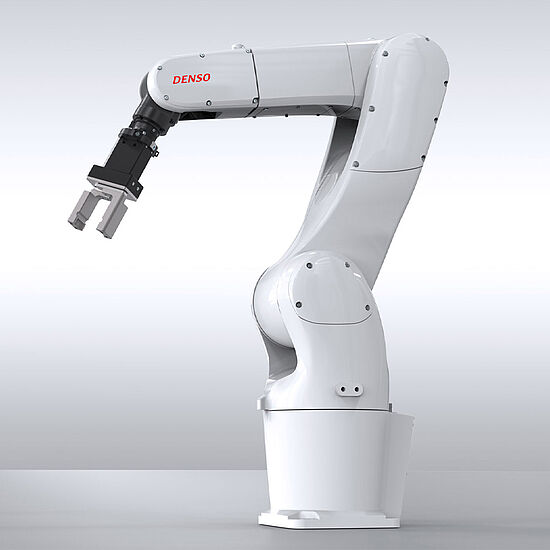

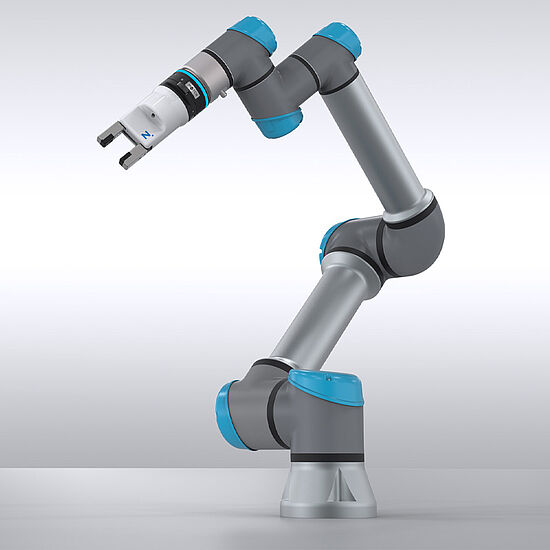

Robotics is becoming increasingly significant in the industry. However, this technology is also gaining ground in areas of daily life where using robots would have been unthinkable just a few years ago. Robots support people, taking care of monotonous and often repetitive workflows, activities that require superhuman strength and tasks that have particularly stringent requirements for precision or are associated with high risks. In recent years in particular, the field of robotics has diversified into various subdisciplines. In addition to conventional industrial robots, the segments of lightweight robots and human-robot collaboration are experiencing dramatic growth worldwide. They also open up new application areas.

This is true regardless of whether you are looking for a configuration for an HRC application on a lightweight robot or a highly complex industrial solution. As one of the worldwide leading suppliers, we provide you with expert on-site application consultation. With one of the largest global component portfolios, we have a solution for any challenge. Whether in the field of tooling machines, consumer goods, the automotive industry or any other sector, we are your partner – fast, precise and flexible.

PRODUCT FINDER FOR ROBOTICS ACCESSORIES

Our intelligent Product Finder makes it easy to find the perfect robot accessories. You will quickly receive well-founded recommendations based on the most important selection criteria. Choose the ideal model for your requirements conveniently online from a wide range of grippers and accessories. Use the clear product information to make an informed decision. Refine your search with additional filters and specific application data for customized results.

Increased overall productivity

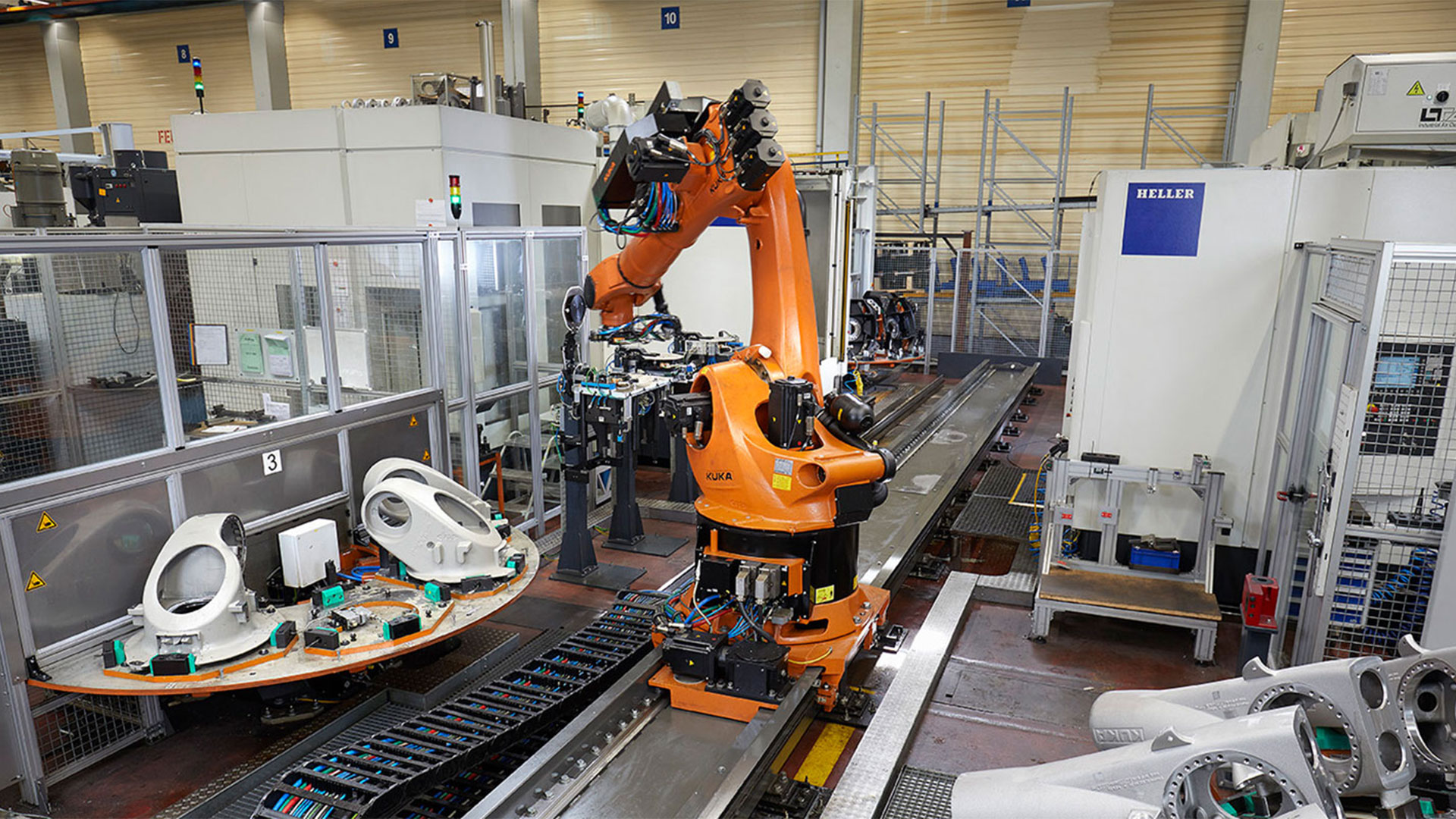

Many convincing points speak in favor of using or investing in a robotic system. One of the most important and promising reasons is the expected increase in production due to faster and more effective processes (24/7 shifts), reduced downtimes and handover times and higher availability.

Increased Quality with High Precision

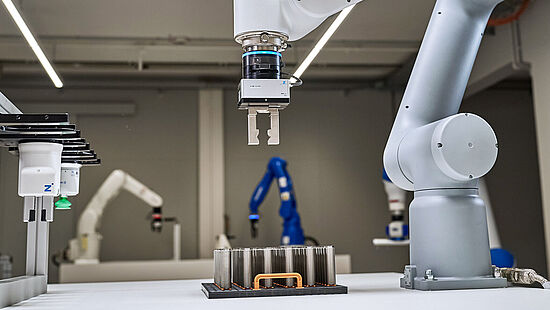

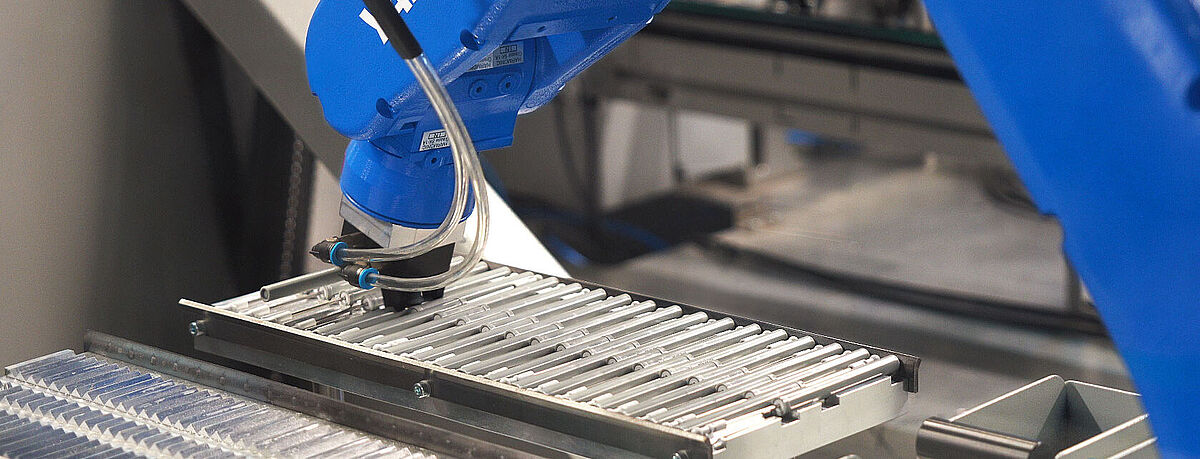

Further benefits of using robotics are the lower defect rates in production. After all, this is where a robot brings its special strengths of precision and repeatability into play. Robots make it possible to manufacture products of consistent quality without any problems. At the same time, there are also fewer rejects.

Adapted and Optimized Production Processes

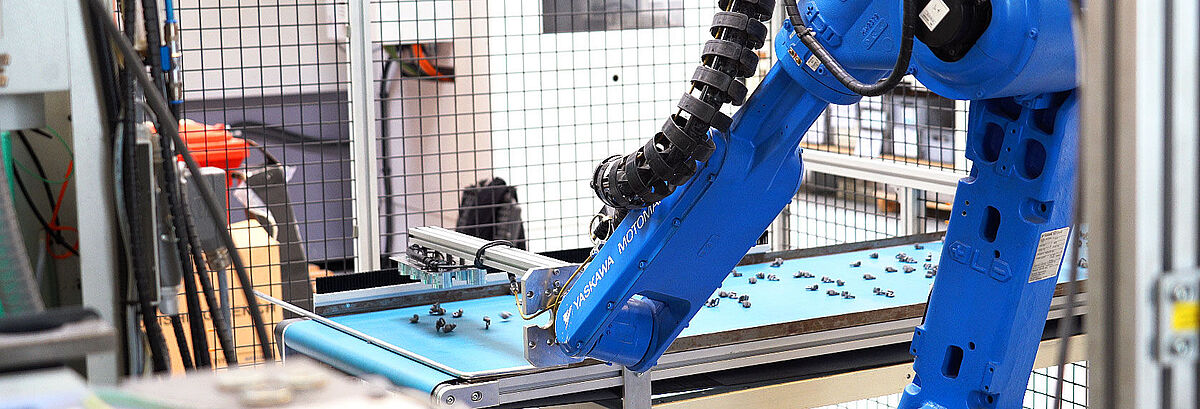

Just one robot cell can process a wide range of products, so production is no longer limited to single orders. This reveals how highly flexible an automation solution is. In the future, automation will allow us to respond even faster to the changing demands of the market. Robotics can also help to convert a production process from a linear system to a flexible and modular stand-alone solution with robots.

Long-term reduction in manufacturing costs

Manufacturing costs are costs that are required to create a product, such as material costs, labor costs and also overhead costs (including energy). In the long run, however, robotic systems can help to reduce these costs. Robots can be used around the clock. This eliminates unnecessary downtime so that work can be carried out with maximum effectiveness.

Implementation of complex production processes

Automation that uses robots also makes it possible to execute complex processes that used to be done manually. For example, today’s robots can take over processes where the parts, travel paths and work environments cannot be anticipated. These processes are supported by vision systems, force-torque sensors, special software – and robots with a high degree of freedom (7-axis robots).

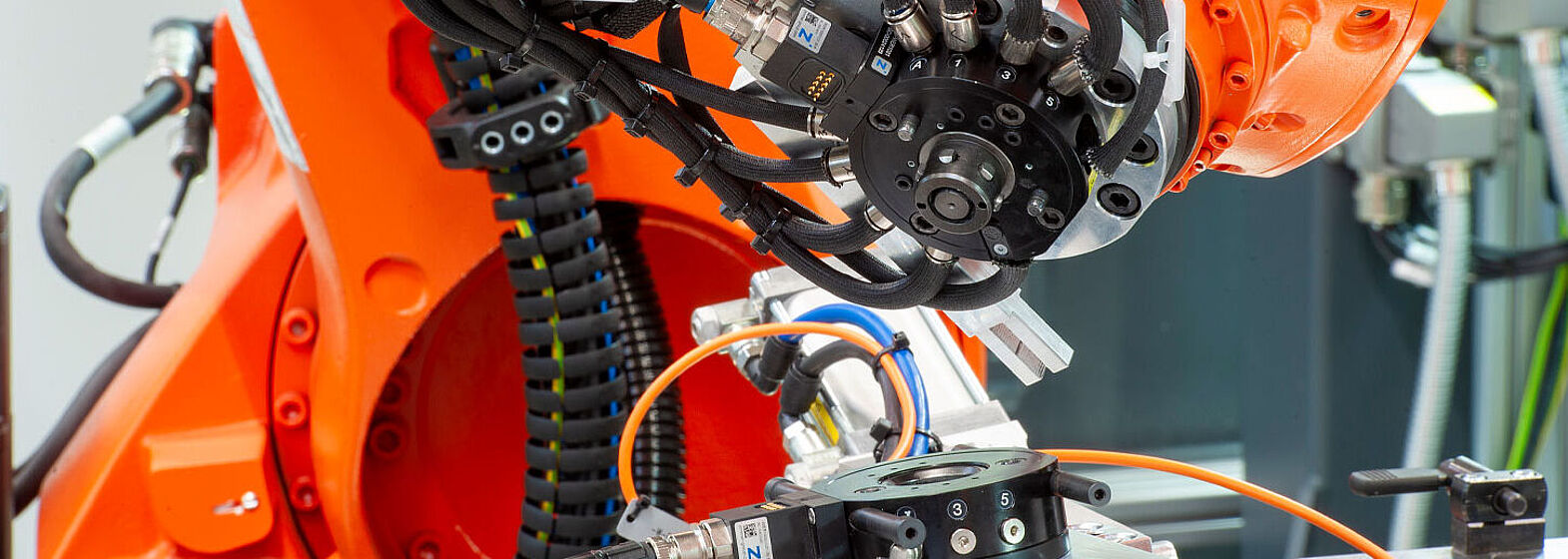

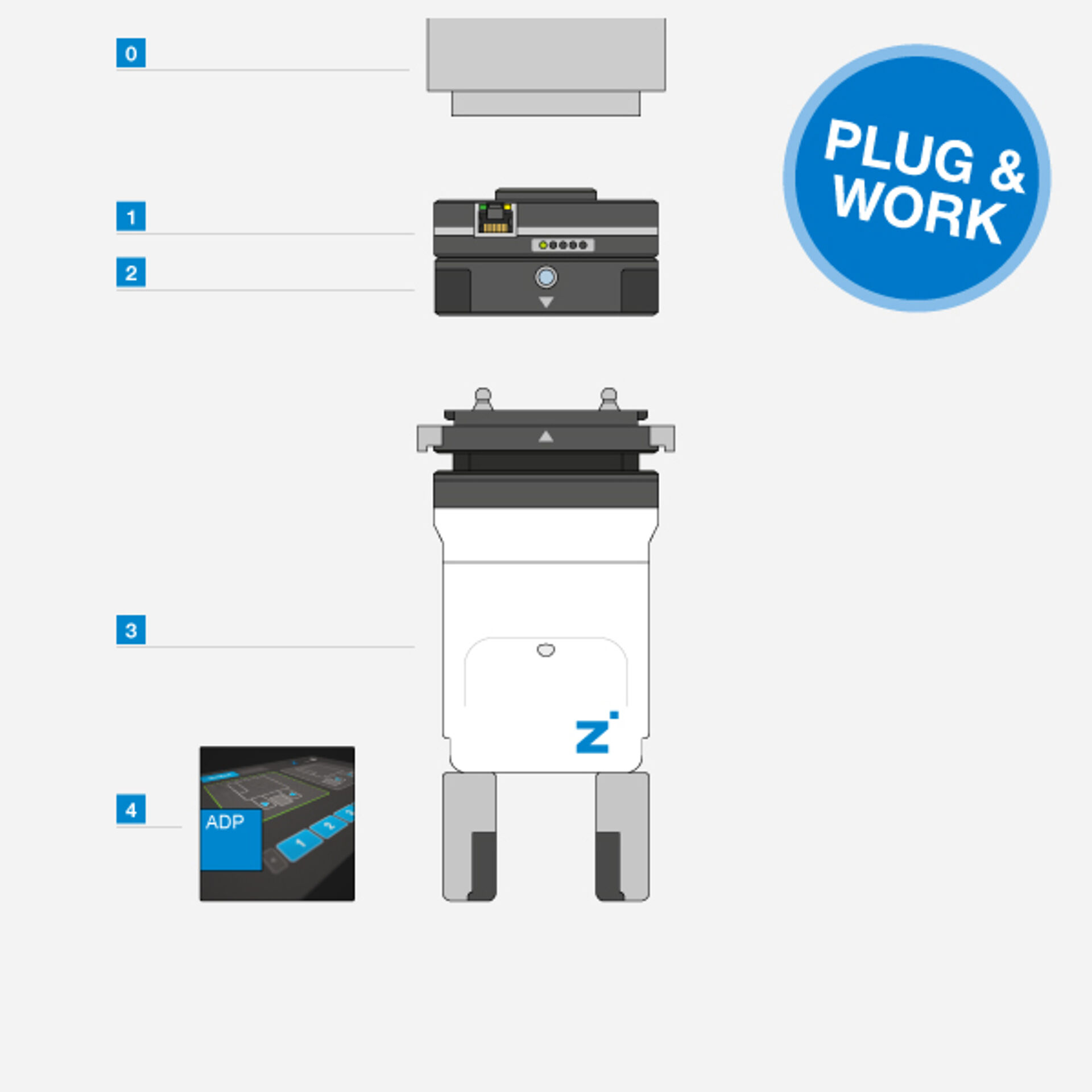

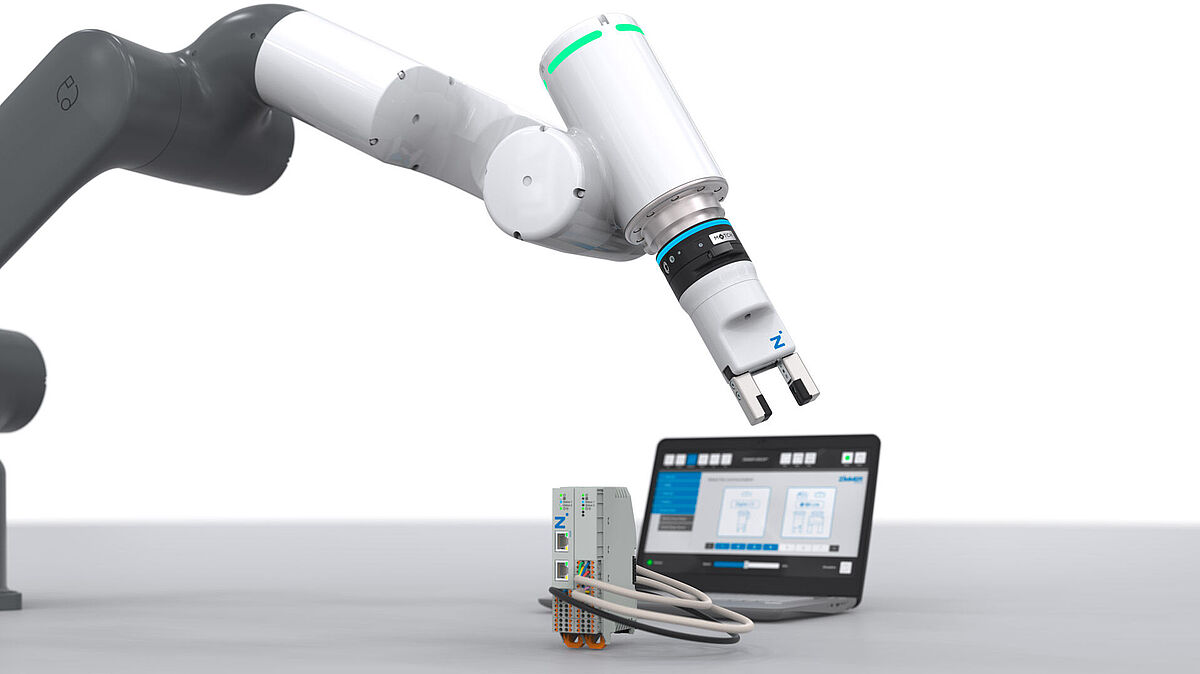

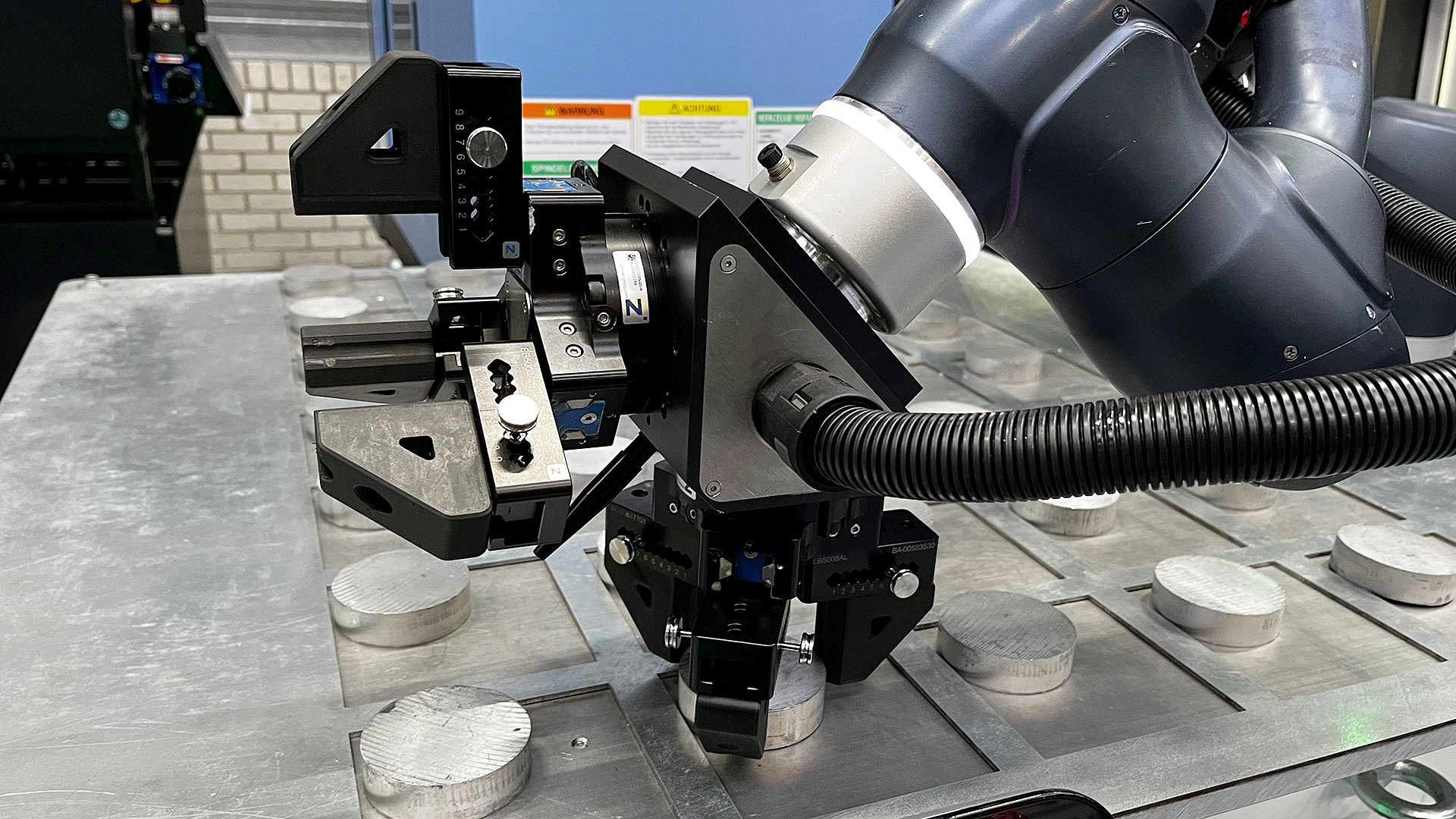

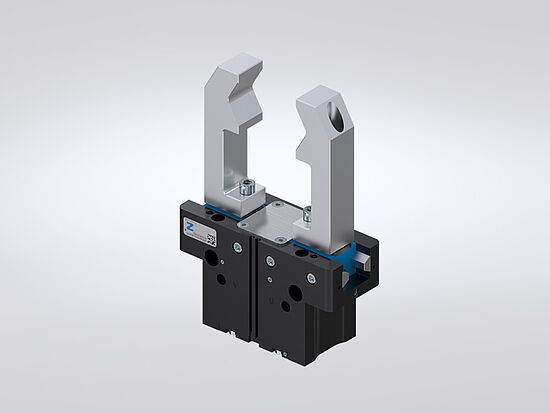

FOCUS: MATCH end-of-arm ecosystem

Standardized interface for robots and end effectors

MATCH has created an entire product ecosystem with a standardized interface. It is compatible with both mechanical and vacuum grippers. The MATCH products work either automatically or manually using the Easy-Click function.

Our conventional tool changers give you the widest possible selection from our product range and our grippers can also handle heavy workpieces, for example.

We offer two different solutions for making it easier to change robot grippers: Our standardized MATCH ecosystem with essential benefits that go beyond just the ability to change grippers and our extensive range of conventional tool changers.

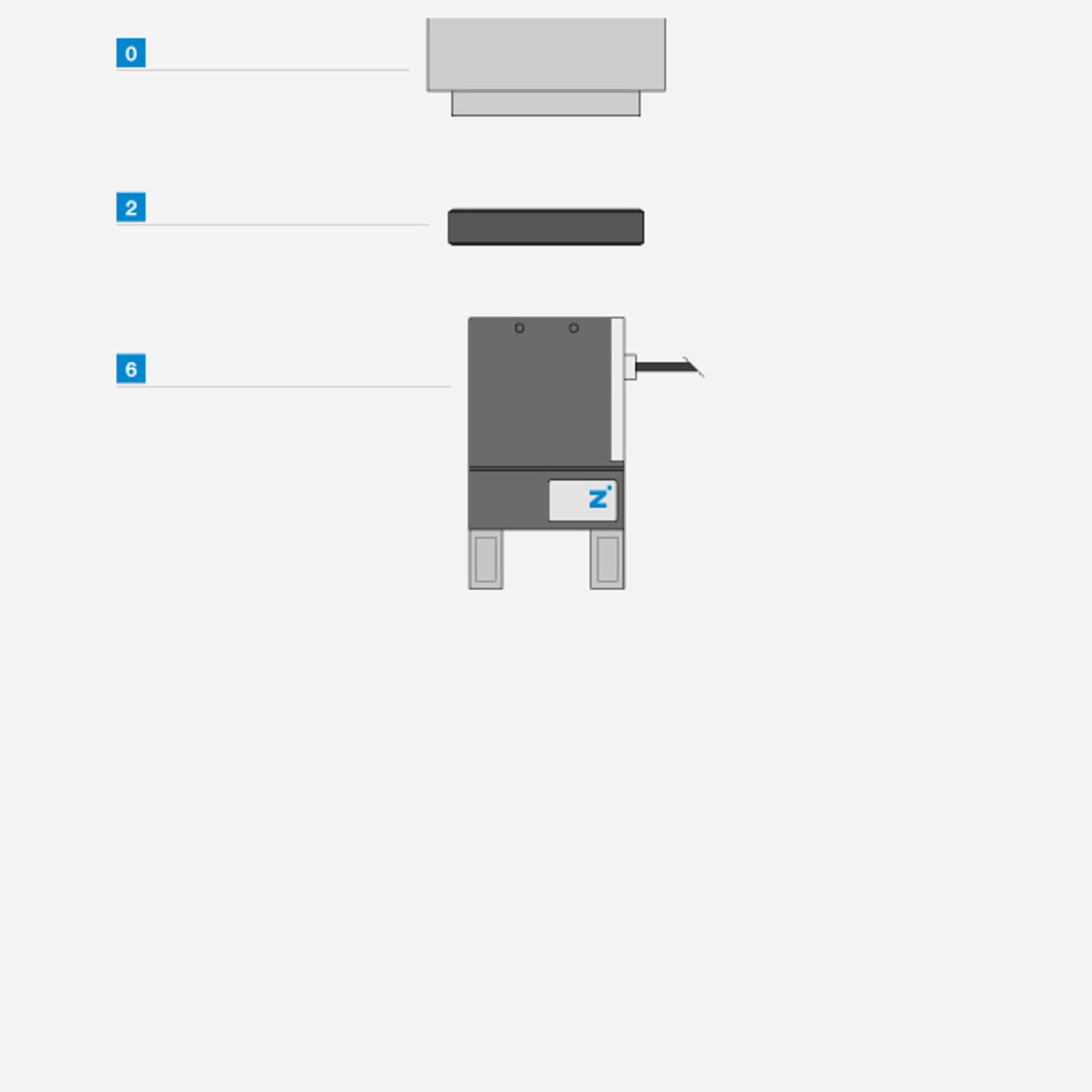

MATCH

Components

0 Robot flange

1 Communication module

2 Robot module

3 MATCH gripper

4 Software

With robot-specific standardized interfaces, the MATCH series offers flexible and fast setup of the robot application. The simple design also allows a high degree of flexibility so that a wide variety of tasks can be performed by one or by various robots.

| | Robotics up to 25 kg |

| | Standardized ecosystem |

| | Plug & Work |

| | Manual and automatic exchange |

| | Gripping |

| | Vacuum |

| | Milling |

| | Special applications |

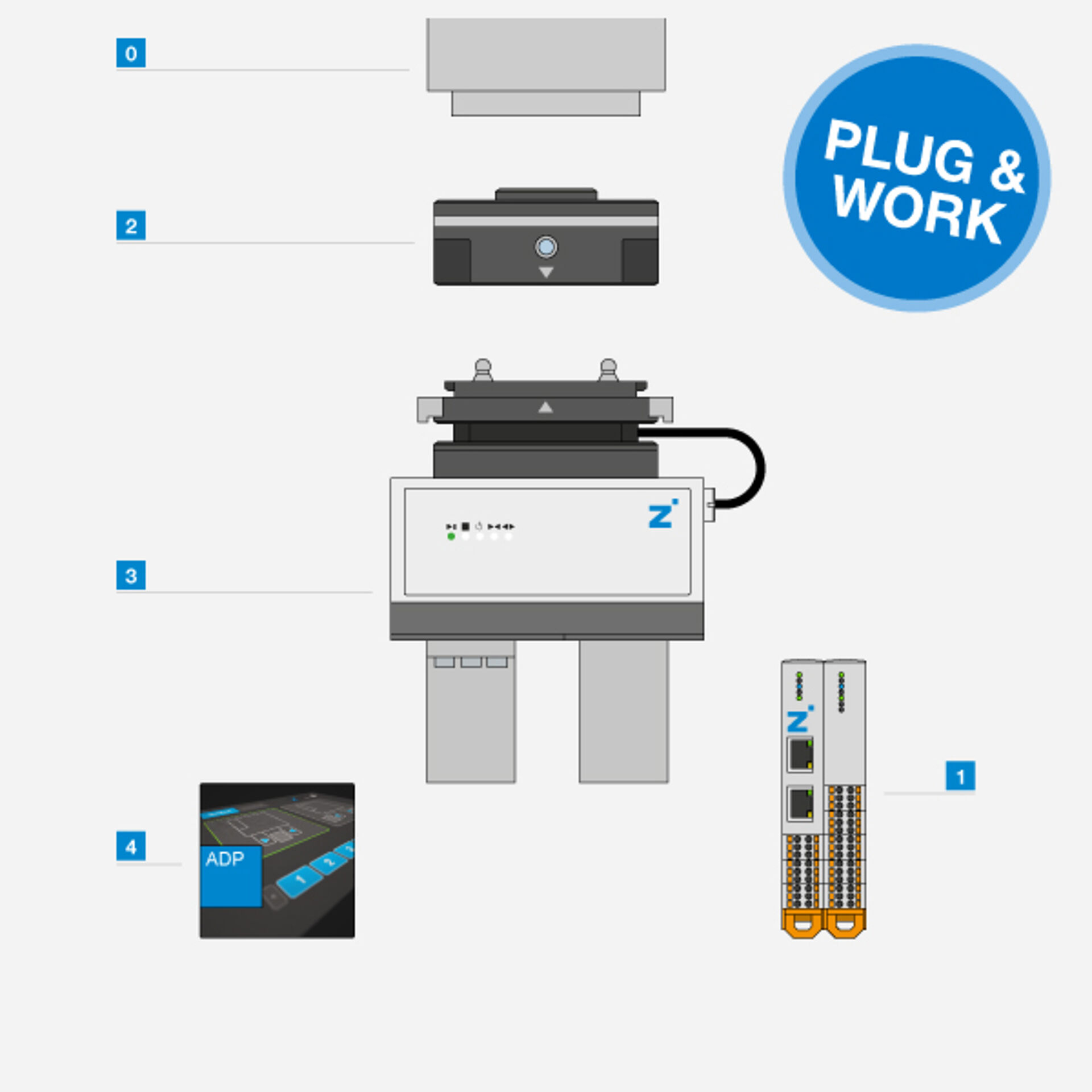

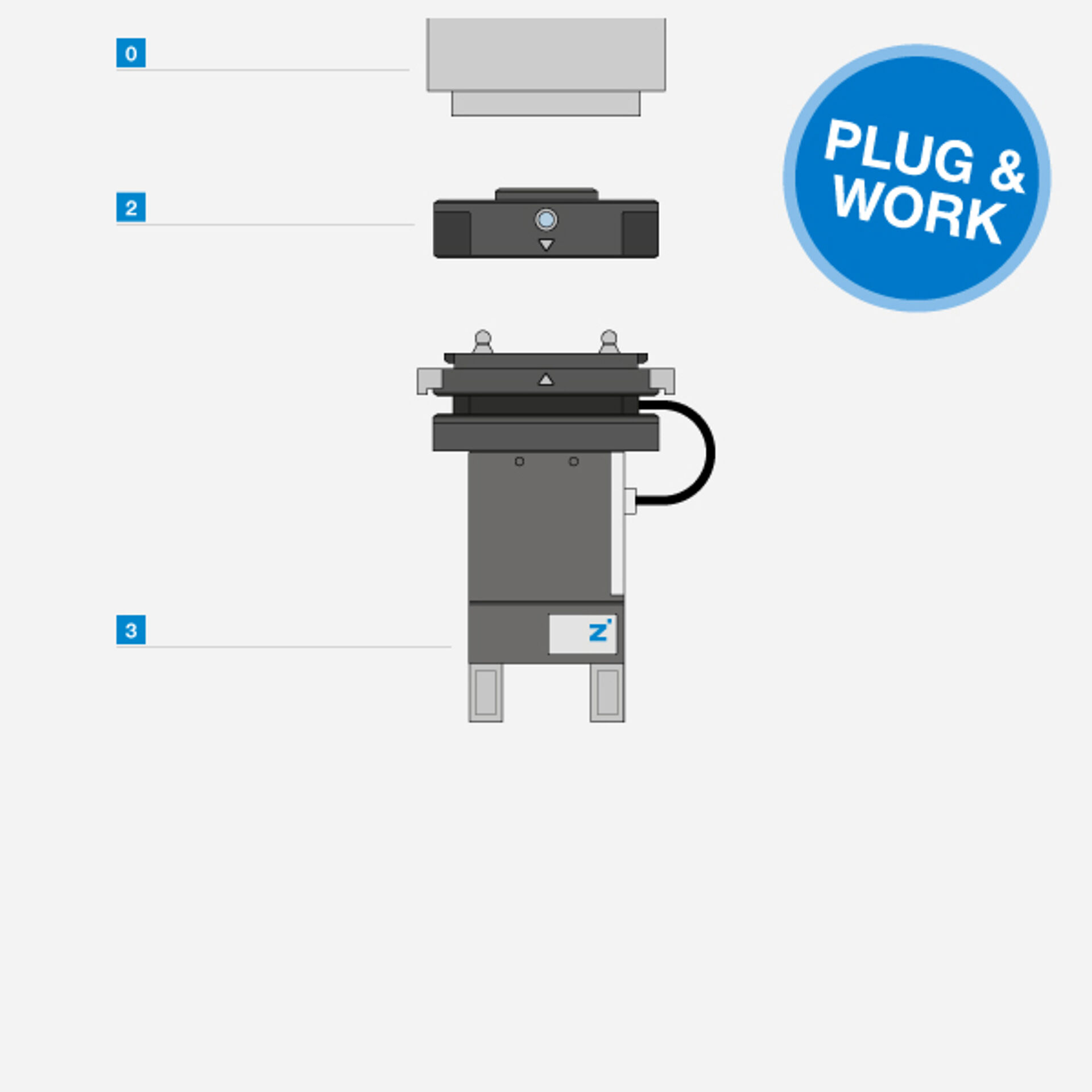

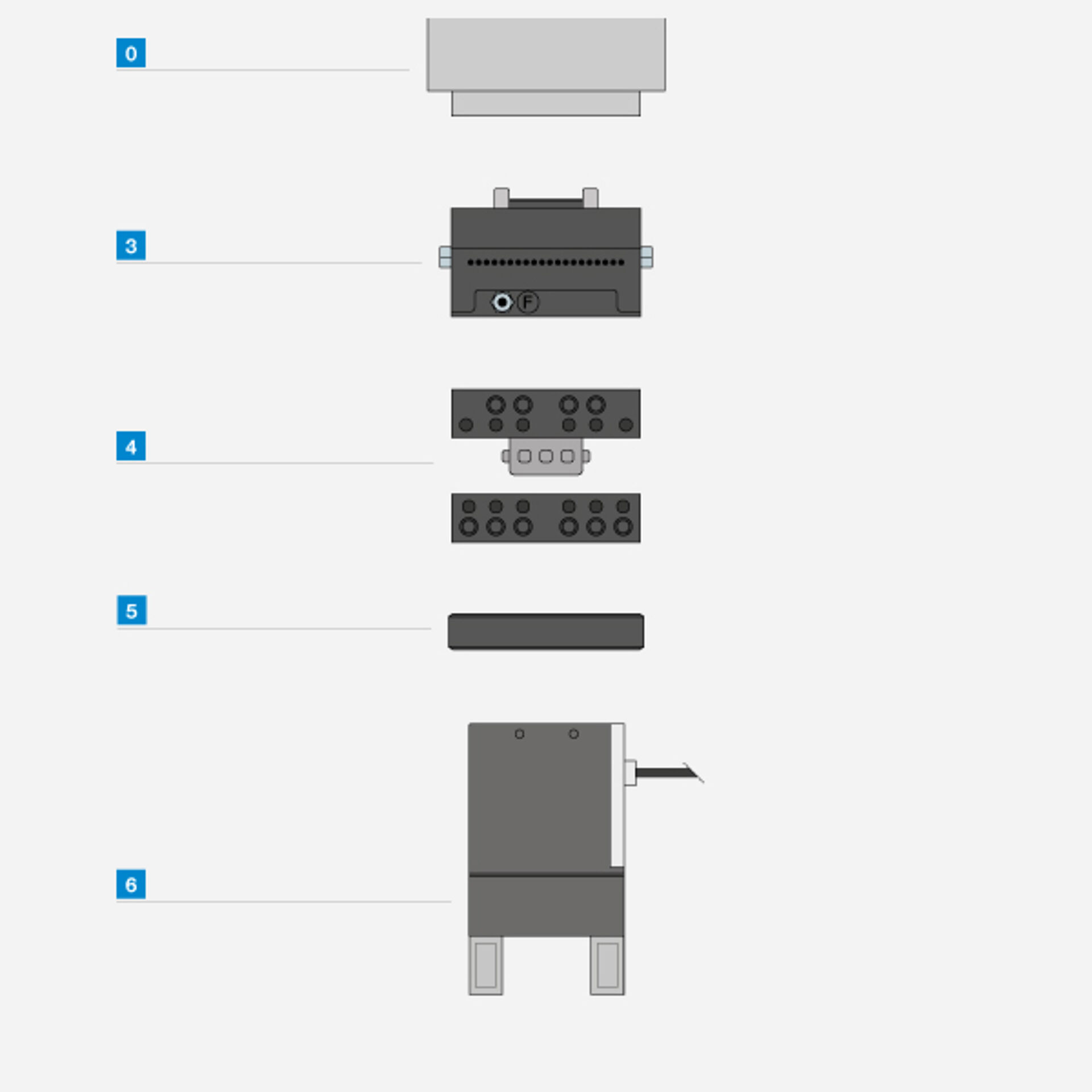

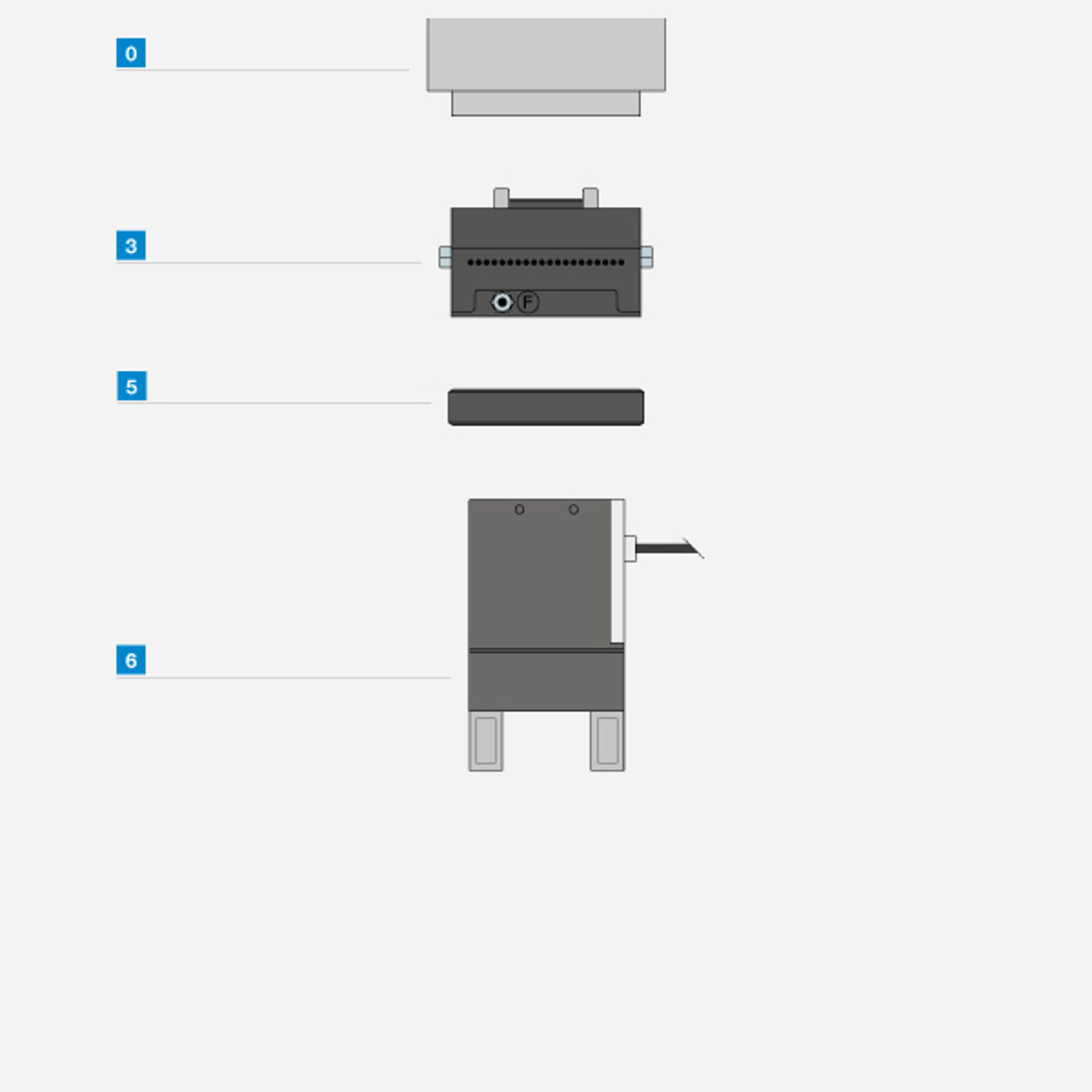

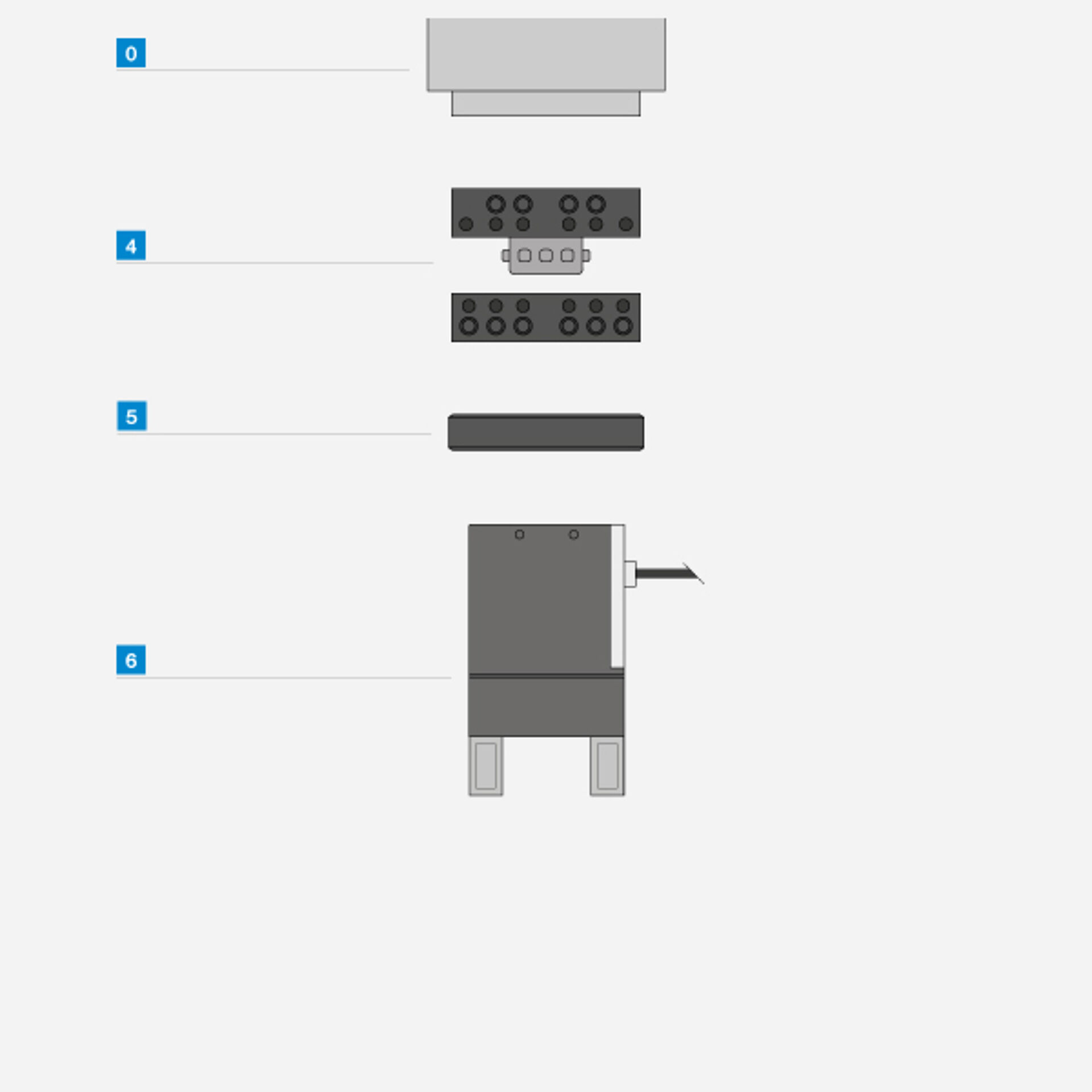

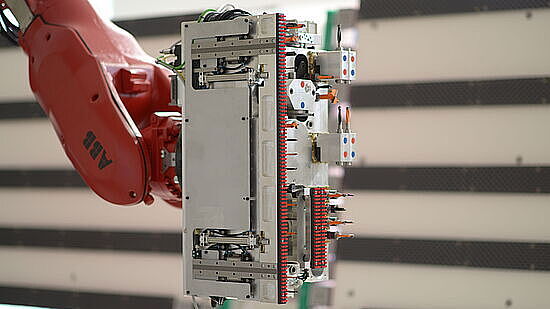

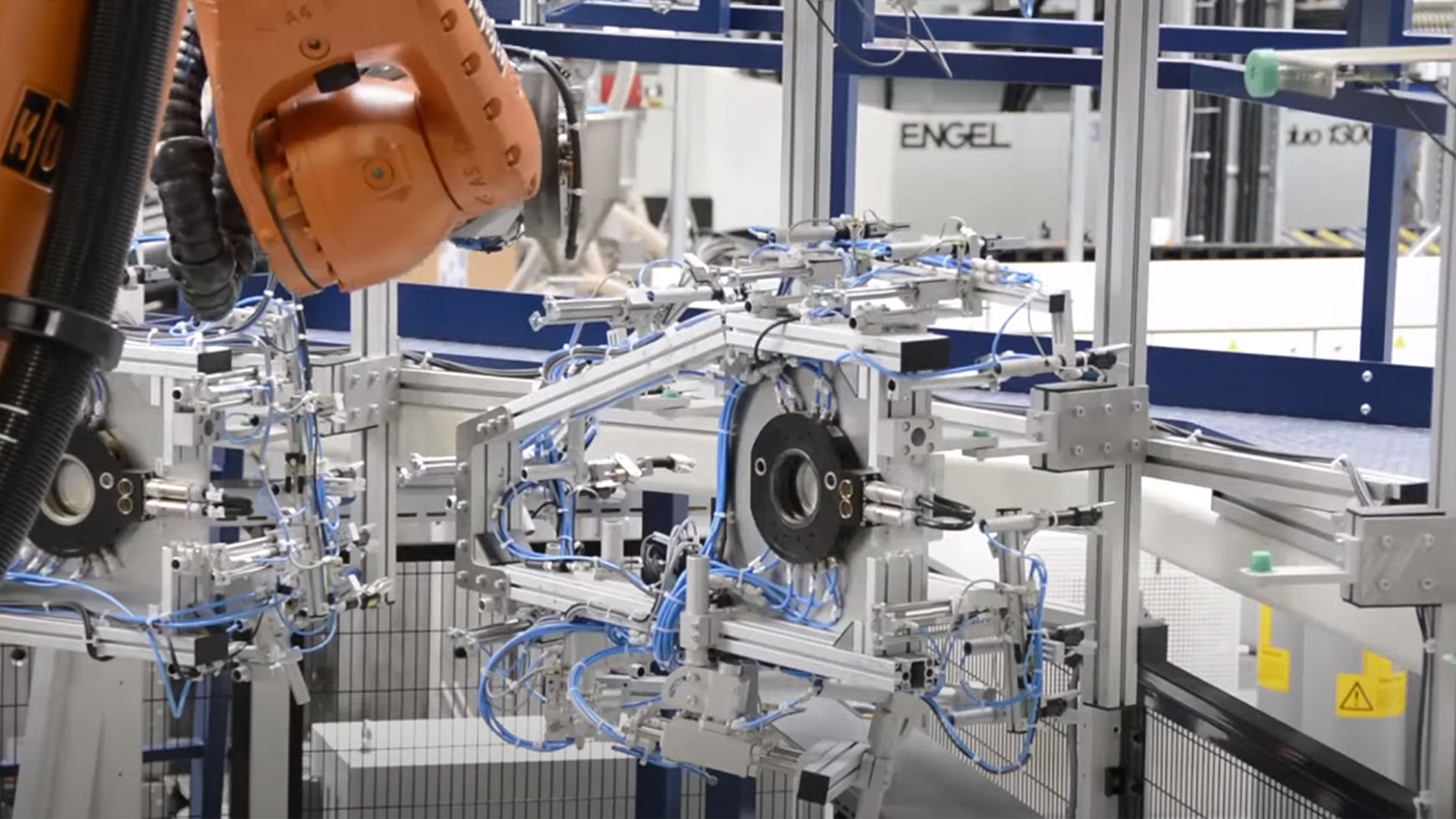

Conventional

Components

0 Robot flange

1 Communication module

2 Adaptation to the robot flange

3 Multifunctional level

4 Tool changer

5 Adaptation

6 End effector

When configuring a robot cell with conventional components, the exact components required for the customer-specific application can be selected from a wide range of products.

| | Robotics up to 1,000 kg |

| | Standardized ecosystem |

| | Plug & Work |

| | Manual and automatic exchange |

| | Gripping |

| | Vacuum |

| | Milling |

| | Special applications |

Compatible robot manufacturers

FOCUS: Robot communication

Find out how the seamless integration of individual components and efficient robot communication can optimize your production processes. Our coordinated components and software modules help you to master technical challenges and implement customized solutions for smooth automation.

Robotics in the real world

The application areas of robots and cobots (collaborative industrial robots) are as versatile as they are essential for the automation of processes. Here we present possible areas of application and configurations at the end of the robot arm.