Conventional industrial robots

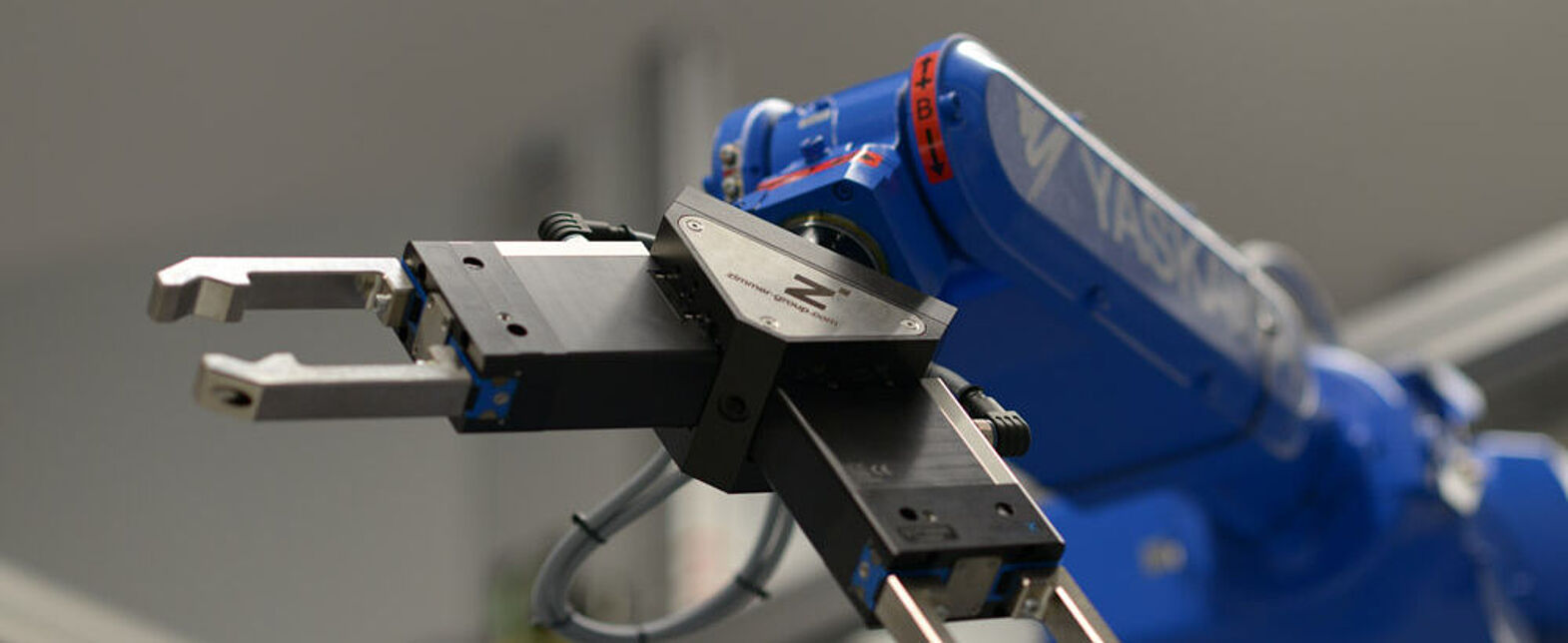

The success story of robot-based automation started in the early 1960s with the field of conventional industrial robots. Since then, the technology has evolved rapidly. Robots became simpler, more versatile and more reliable in installation, programming and maintenance. The Zimmer Group launched the world’s first mass-produced gripper in 1980 and has played a key role in the field of end-of-arm tools ever since.

Do you need advice or have questions about a specific robot application? Then we look forward to hearing from you!

Your benefits:

- Quick and easy integration into existing systems

- Maximum performance with maximum safety

- System landscape for the entire value chain

- IP protection class for all environmental conditions

- Energy-efficient in production and use

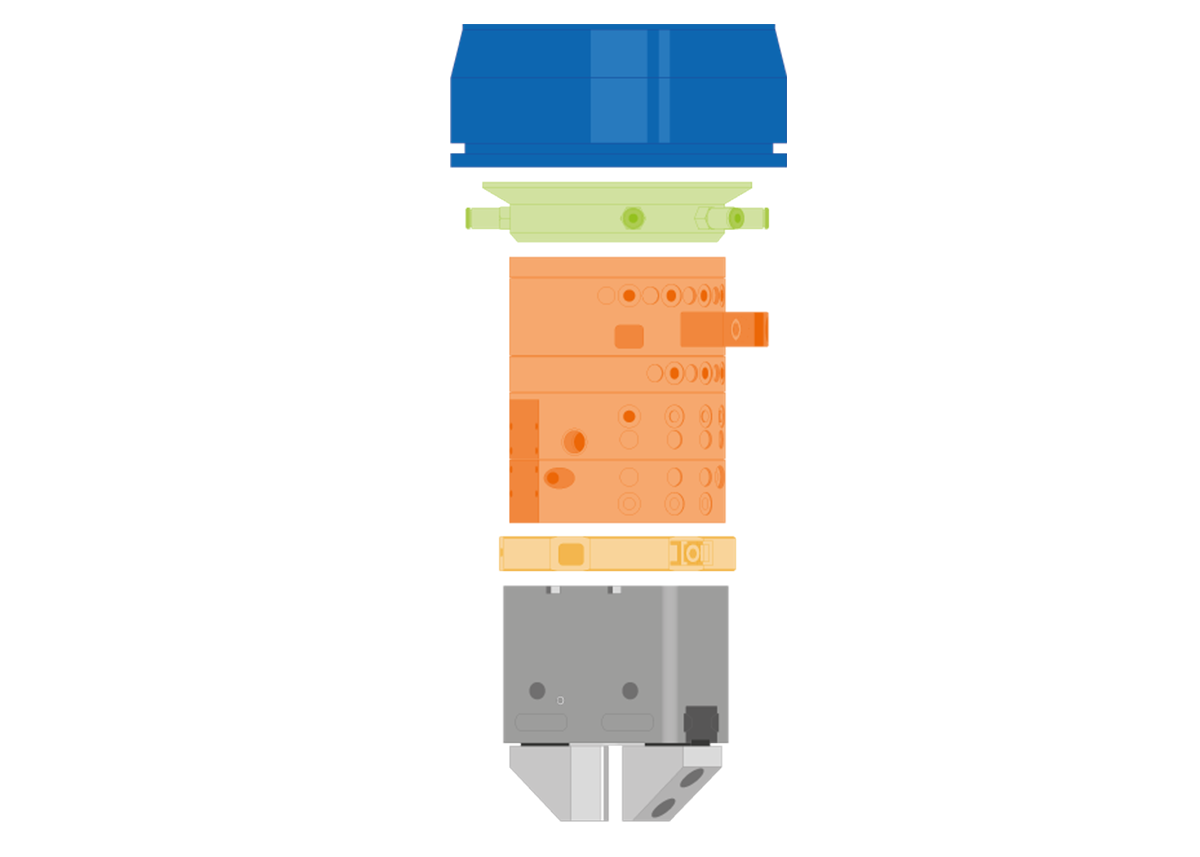

CONFIGURATION LEVELS on the robot arm

more

more more

more

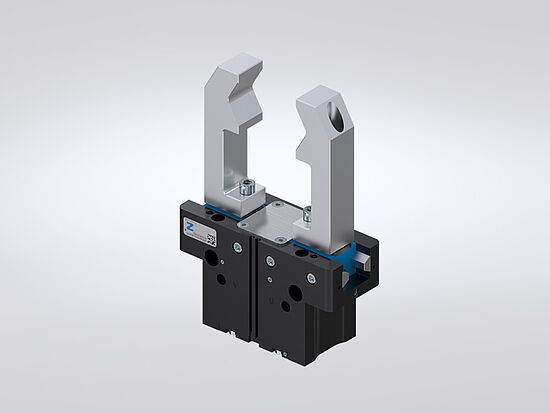

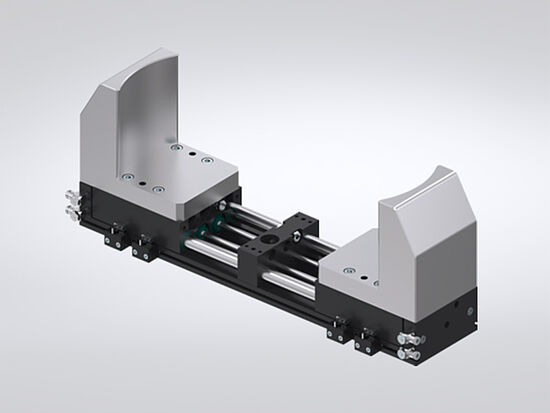

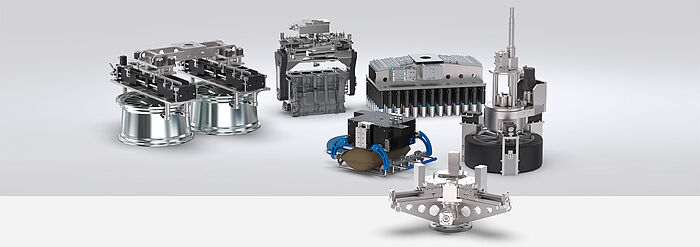

COMPONENTS for industrial robots

Over 3,000 standardized grippers, swivel units, robotics and much more. We offer a complete selection of technologically leading products that are ready for rapid delivery.

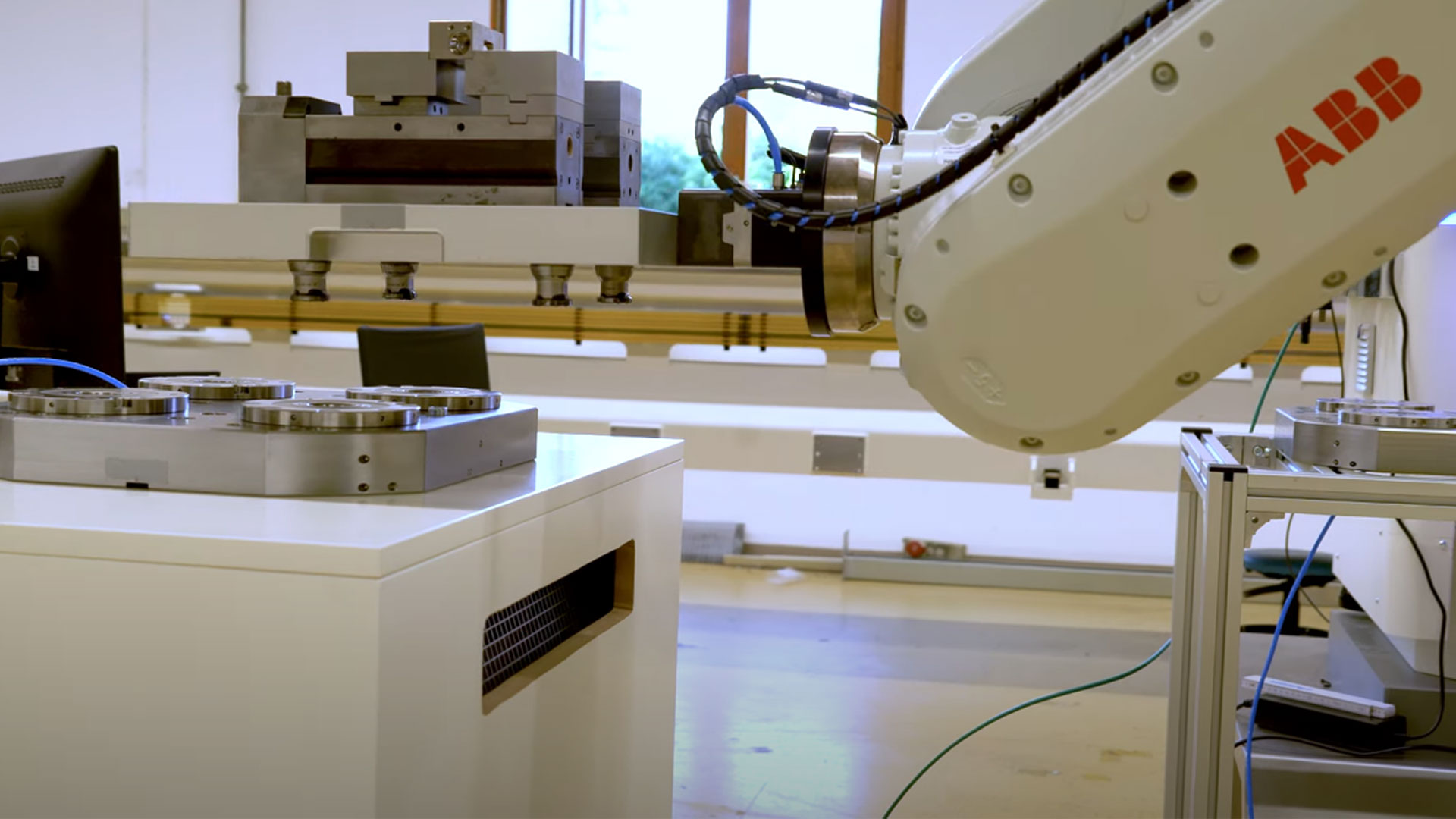

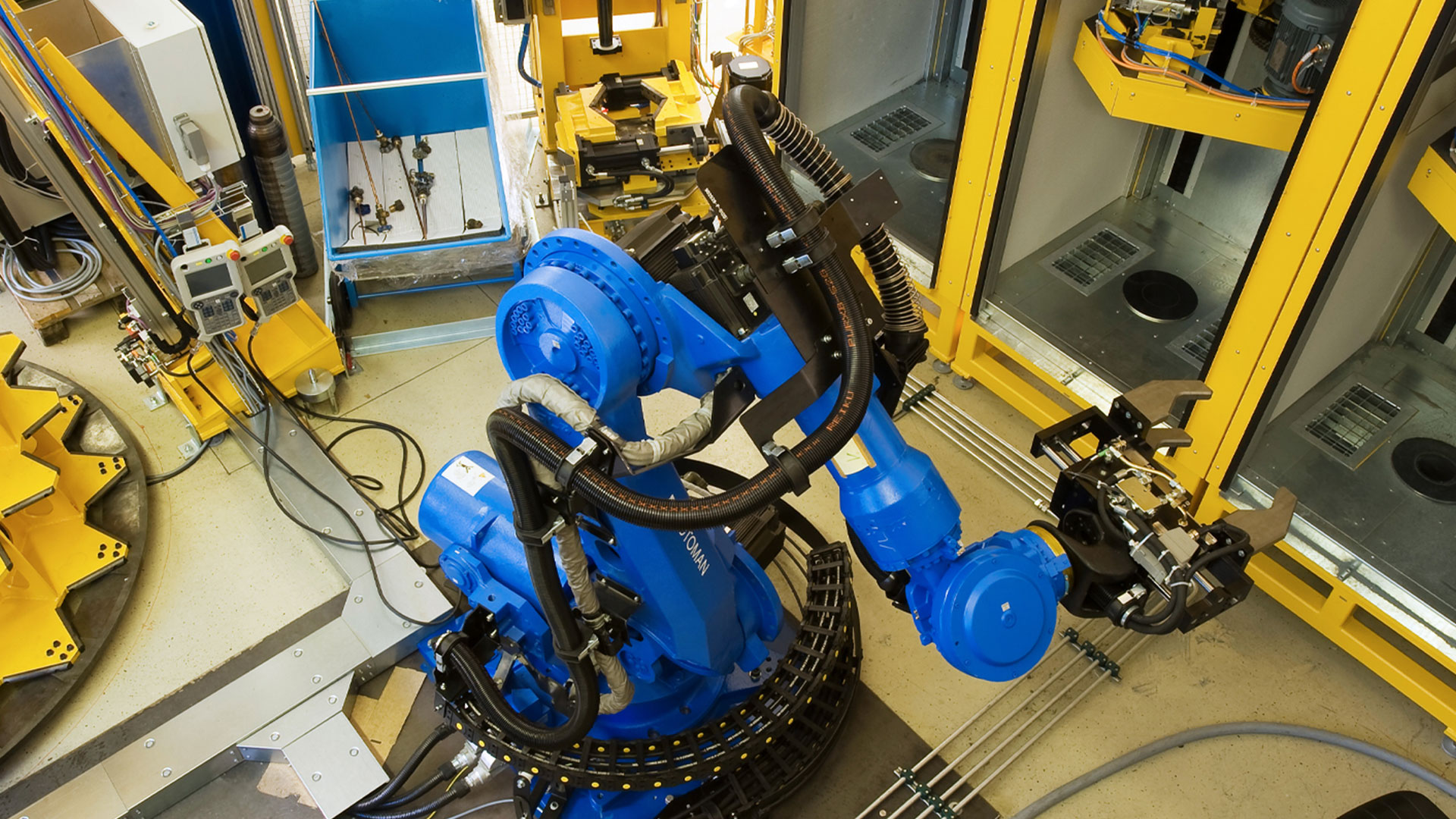

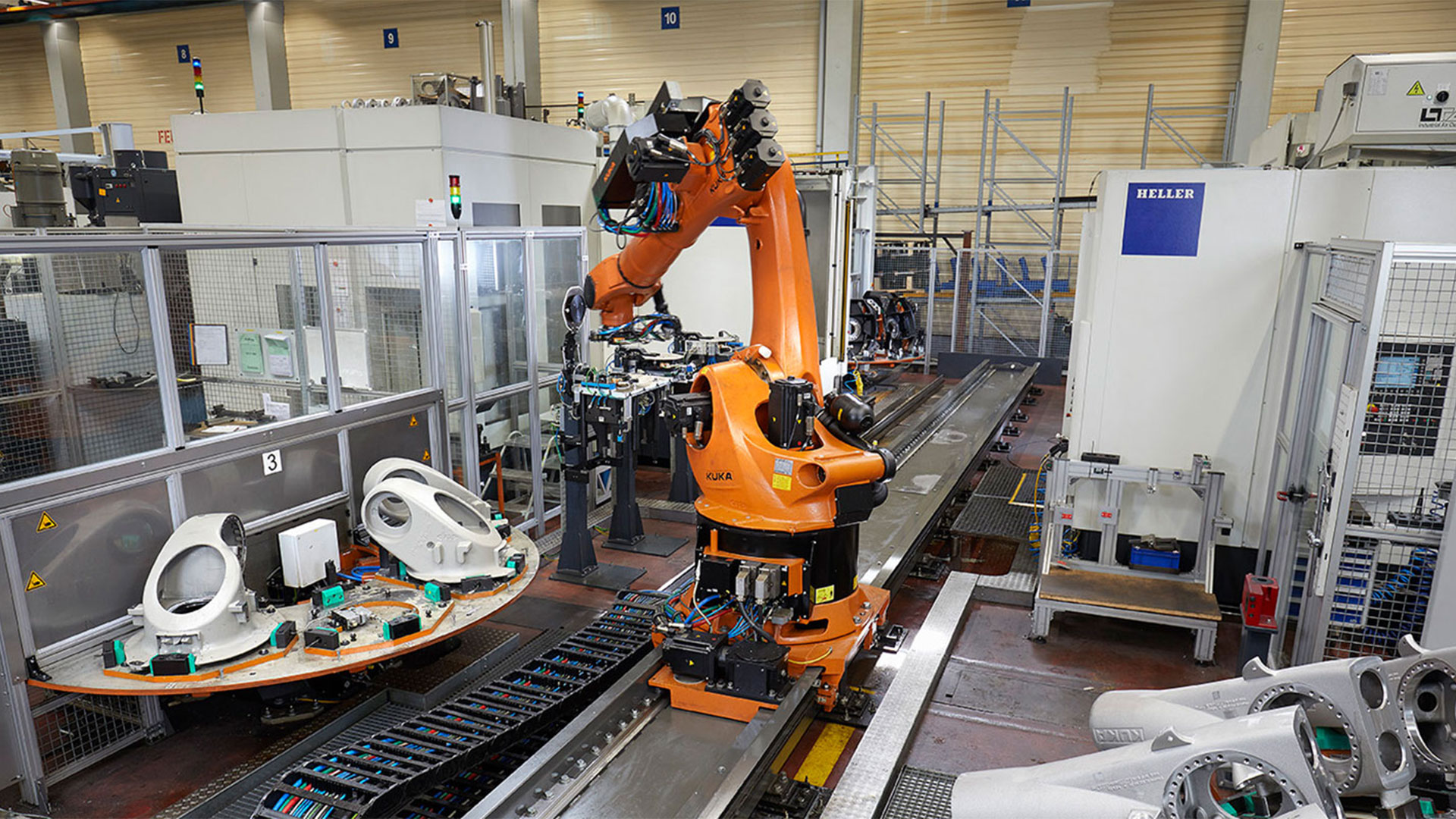

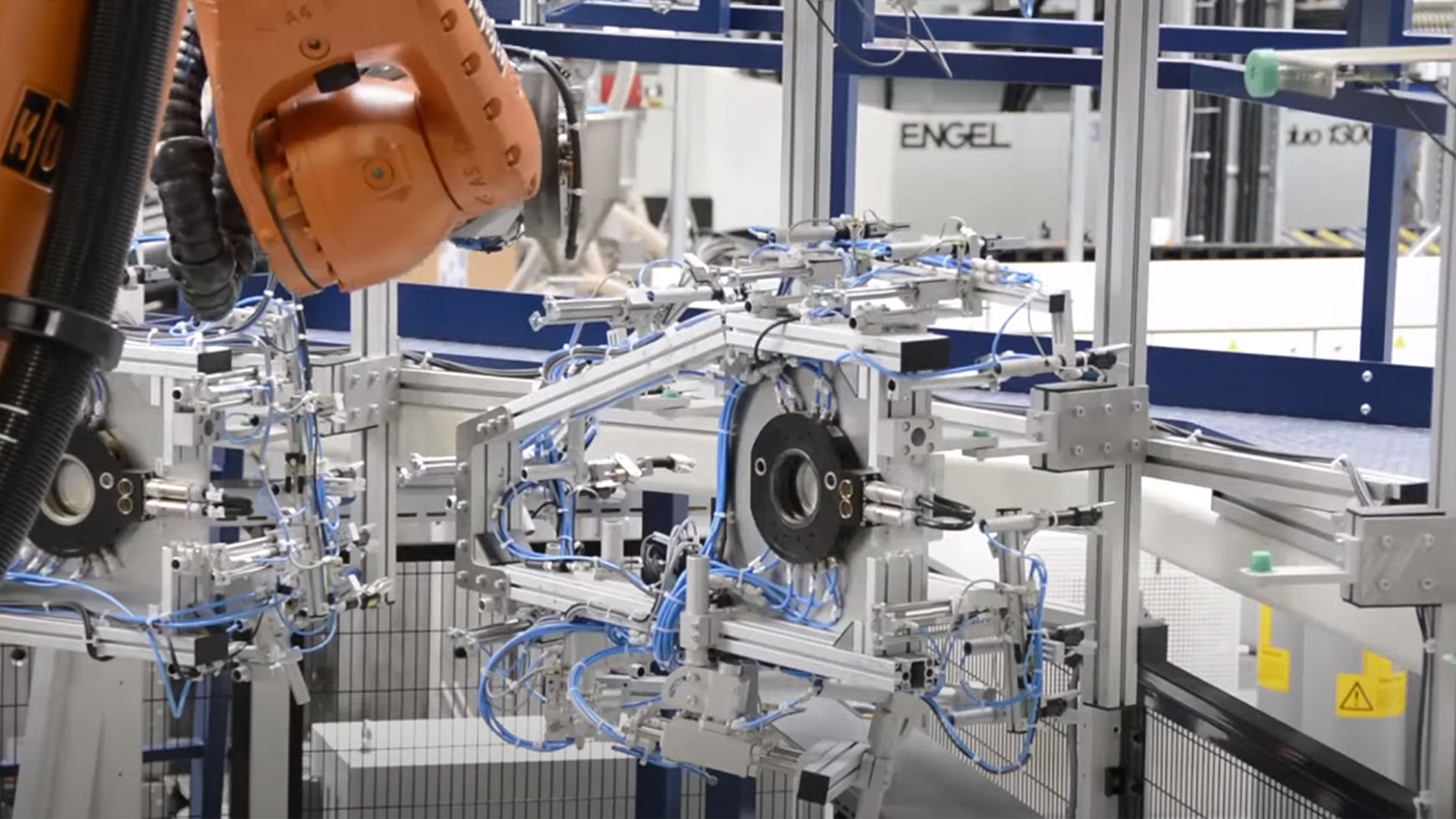

END-OF-ARM TOOLS

The Zimmer Group has been offering end-of-arm tooling systems for over 30 years. Applications include installing power trains, loading machining lines in the automotive industry and machining furniture parts in the furniture industry.