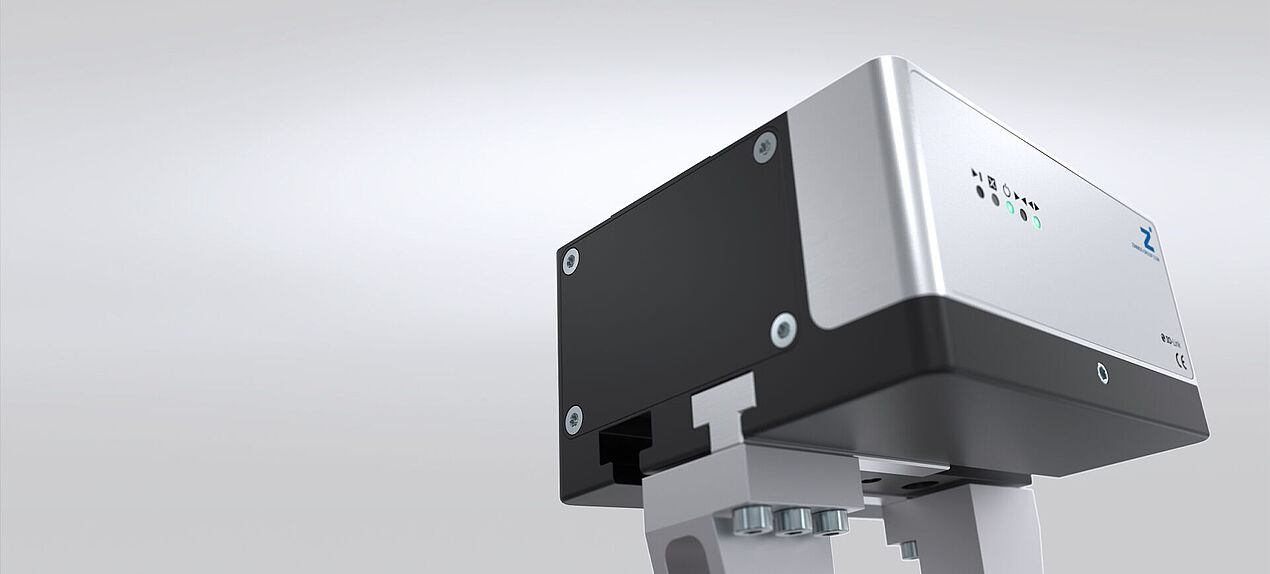

POWERFUL AND FLEXIBLE WITH THE 6000 GRIPPER FAMILY

Convince yourself of the electric grippers in a class of their own! The Zimmer Group 6000 gripper family can be positioned flexibly, has a high power density and impresses with its impressive durability (up to 5 million maintenance-free cycles). Individual force adjustment as well as position and speed control optimize the Series 6000 grippers for use in sensitive, process-safe areas such as laboratories or medicine. IO-Link compatibility and the storage of up to 32 workpieces offer maximum flexibility. Powerful handling including mechanical self-locking or sensitive precision – the grippers in the 6000 product family are versatile and can be used in a wide range of industries.

6000 product family

Are you looking for grippers with high power density or for sensitive, fast handling? The Zimmer Group’s 6000 series offers you flexible solution components for your requirements. These are your advantages:

- Electric and positionable – for flexible handling

- Up to 5 million cycles without maintenance – for smooth production

- Up to 32 workpieces can be stored

- Integrated position sensing via IO-Link

- Force version -03 for heavy workpieces; sensitive version -31 for precise gripping

Gripping force retention as standard

Safety in production as standard! The gripper version -03 of the 6000 series is equipped with mechanical self-locking as standard. This ensures that the workpiece is held firmly in the gripper and that even in the event of a power failure or emergency stop, safety for people, the workpiece and the production system is guaranteed.

Mechanical emergency release

The 6000 series has a mechanical emergency release – an important safety feature! The gripper can also be opened manually in the event of a system or power failure. A screw accessible from the outside can be used to move the worm of the self-locking gear, open the gripper and remove workpieces. The emergency release also ensures improved work safety if, for example, the gripper has to be opened without a power supply in the event of an emergency stop due to personal injury. Maximum safety for the user and the machine.

Protected from external influences

Different areas of application place diverse requirements on the components. With protection class IP54, they are protected against the ingress of both spray water and dust. The 6000 series can also be equipped with a protector to minimize wear on the gripper in adverse environments. A mechanical superstructure on the gripper offers protection against external influences such as cooling lubricants containing water and oil.

Clean room class 4

We guarantee reduced particle emissions for all Series 6000 grippers. The entire series is TÜV-certified in accordance with DIN EN ISO 14644-1 and therefore suitable for clean room class 4, making the grippers ideal for sensitive applications in the electrical industry, as well as in the medical sector and in laboratory environments where clean room classes are required.

UL certification for the North American market

The world’s first gripper with UL certification not only guarantees compliance with the highest safety standards, but also that the grippers meet the regulatory requirements in North America. This saves time and costs during project planning and machine acceptance and ensures the smooth use of our components in production plants. With this certification, we offer you a crucial competitive advantage: safety, efficiency and confidence in the quality of our products.

Safe Torque Off for maximum safety

Particularly in the field of collaborative robotics, as is often the case in laboratories, the safety of employees is paramount. For this reason, the 6000 series with the Safe Torque Off (STO) safety function has a separate cable with two safe NC contacts. This means that in the event of an emergency, the power supply to the drive is interrupted directly in the gripper, so that it is immediately torque-free. Movement can be resumed after the contacts are closed without any restart time. This function is available as an option and corresponds to stop category 0 in accordance with EN 60204-1, offering reliable protection against unwanted injuries.

IO-Link on board

We rely on IO-Link compatibility to integrate Zimmer Group components easily into your system. IO-Link is the transmission technology of the future and offers you a multitude of advantages in the world of Industrie 4.0. This means that we not only guarantee simple implementation and hot-plug-capable control – a total of 32 workpiece data records can also be programmed into the grippers. In addition, IO-Link enables integrated sensing.

Our step-by-step guide shows you how to integrate your gripper into the PLC environment:

THE RIGHT GRIPPER FOR YOUR APPLICATION

Sensitive handling of fragile vials? Or powerful gripping of metal workpieces? With the Series 6000 grippers, we offer you a variant tailored to your requirements. The electric drive and free positionability offer maximum flexibility for a smooth production process in line with Industrie 4.0 standards.

GEH6000-31-B

Precise

The brushless drive technology and integrated transmission enable the highest level of setting precision on the gripper and make the GEH6000-31-B ideal for handling more sensitive materials, such as in the food or pharmaceuticals industries.

Fast

A servo drive with integrated controller guarantees maximum functionality and individualized control of the speed – for rapid sequences of automated movements.

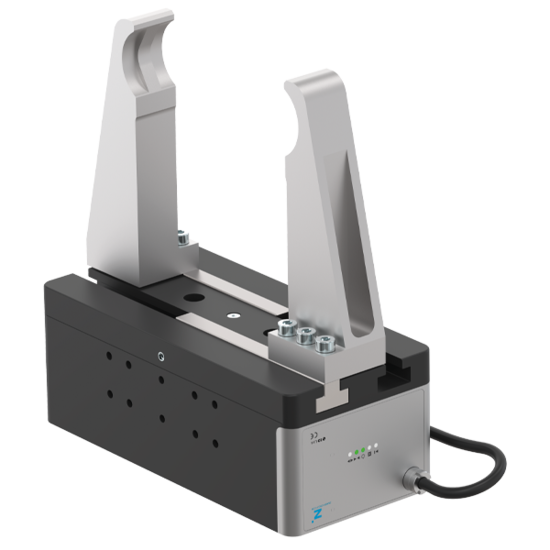

GEH6000-03-B

Powerful

The precise T-slot guide ensures that high forces and torques are absorbed, while the rack and pinion gear enables high force transmission. The GEH6000-03-B version is thus ideally suited for gripping heavy workpieces.

SMART COMMUNICATION MODULES

- Translates IO-Link to digital inputs and outputs (Digital I/O), as well as from Digital I/O to IO-Link

- Very easy control of intelligent IO-Link grippers via 24 V digital I/O

- Configuration and training is done with the associated intuitive guideZ software

- Can be used with one or two grippers, depending on the required flexibility

- Up to 15 different workpieces can be taught in for one gripper

Products

Accessories

To optimize the use of Zimmer Group grippers in your system, we offer a wide range of gripper accessories,

such as universal, adjustment or exchangeable jaws.

SYSTEMS

In addition to our standard gripper components, we also offer customized system solutions – from specification to implementation – to meet your specific requirements. By using our proven modules, we specialize in offering high-quality solutions at competitive prices. We offer ready-to-connect system solutions for your applications and have a wide variety of modules in our portfolio. These are very easy to adjust and configure and can be conveniently adapted to your particular application. Our proven system solutions, of which more than 9,000 are already in use on the global market, have a long service life with minimal maintenance requirements and are also Industrie 4.0-capable!