Energy elements

The most important accessories for tool changers are energy elements that equip you to transfer a wide variety of media. Whether pneumatics, hydraulics, coolant, load current or IO-Link – with our broad portfolio, the entire range of transmission types is available to you.

FAQ – Frequently asked questions and answers about energy elements

To find the right energy element, the selection is reduced using a pre-filter. If not all information is available yet, meaning that the filter cannot be set, it is possible to display all energy elements that match the previous filter at any time. If the energy elements are displayed, they are sorted by tool changer and by number of media feed-throughs.

We offer energy elements for transferring the following media as standard:

- Pneumatics

- Hydraulics

- Load current

- IO-Link

- Coolant

- Signal current

If none of our energy elements are compatible with your application, we can surely find another solution Please contact us for more information!

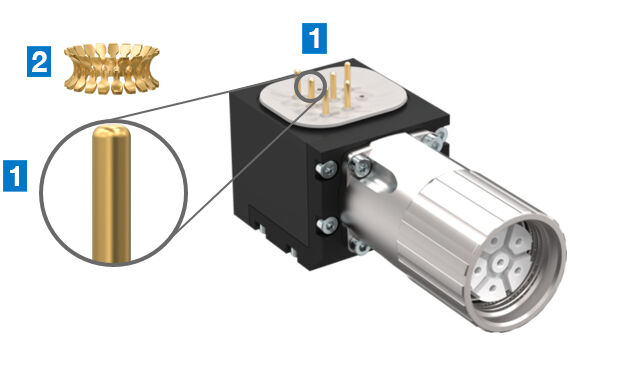

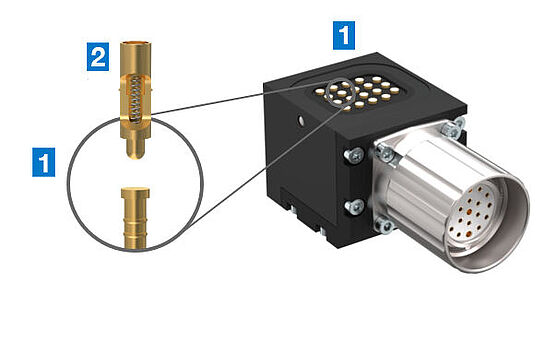

We offer spring contacts and plug connections for our energy elements. Depending on the application, both connections have their advantages. Plug connections (see illustration on the left) have a long service life and are less susceptible to dirt and moisture. They are also suitable for high voltages of up to 600 V, currents of up to 15 A and high signal quality.

Spring contacts, on the other hand (see the illustration on the right), are suitable for voltages up to 60 V and currents up to 3 A. They require less installation space and are very easy to detach from each other, so you may be able to dispense with a storage station with a pull-off device.

- Loose part

- Stationary part

Plug-in connectors

Spring contact

Hydraulic energy elements are designed for a pressure of up to 150 bar. The pressure that is present shortly before and during the coupling or decoupling process is referred to as the coupling pressure. Depending on the energy element, this can also be max. 15 bar or less. To avoid leakage during coupling and decoupling, the maximum coupling pressure must be taken into account. We generally recommend switching off the pressure using a valve before coupling or decoupling so that there is only a residual pressure of < 15 bar.

At a pressure of 30 bar or more, high forces act, which can prevent the elements from being optimally connected. Without appropriate measures, this can lead to leakage. We therefore recommend additional support or locking of the corresponding energy elements.

- Support on the robot

- Support using a

folded plate or

using an adapter plate - Pneumatic locking

Customizable elements are soldered and assembled by the customer. You can find more information on assembly in the corresponding installation instructions.

Our energy elements are supplied with a radial plug orientation. If an axial plug orientation is required for your application, you can easily implement this. To do so, the eight screws must be loosened, then the bracket with connector plug is twisted and refastened with the eight screws – and you’re done!

Radial plug orientation

Rotate plug

Axial plug orientation

There are basically several options for integrating electrical energy elements into the system. These also depend on the energy element in question.

- Free cable end: Free cable ends are available for the user-fabricated energy elements of the WER1000 and WER2000 series.

- Energy elements in the WER1000 series have a connector plug. You will find the corresponding round plugs or prefabricated cables in our product range.

- The WER3000 series has plugs. You will find the corresponding round plugs in our product range. You can fabricate these yourself. We are also happy to offer you prefabricated cables on request.

- Energy elements with other connectors or with a direct cable outlet are also available on request.

If you wish to replace electrical energy elements from the WER04, WER05 or WER106 series (discontinued models) with elements from the WER3000 series, you should note the following. You can continue to use the round plugs on the stationary part side without restrictions, as long as you use the same number of poles. On the loose part side, the round plug (6) must be replaced, as the loose part of the WER3000 series has a union nut, whereas the union nut is already integrated in the round plug of the WER04 / WER05 / WER106 series. This can also be seen in the illustration. In addition, energy elements from the WER3000 series require a corresponding adapter plate (5).

- Stationary part WER05

- Loose part WER05

- Stationary part WER3000

- Loose part WER3000

- Adapter plate

- Round plug/cable connection

If required, you can reorder the individual spring contacts for the customizable energy elements. For our other elements, please return the energy element to us in the event of damage, as special devices are required for the assembly steps.

We can offer you energy elements with ATEX approval on request. Please contact us for more information!

The hot-plug function describes the possibility of adding or removing components from a system during operation or while the power is connected. The main feature of the hot plug is that the system is not interrupted.

Hot plug is used, for example, for energy elements or quick-change systems in the LWR series.