Automated processing of wood & composite materials

The Zimmer Group is one of the world’s leading manufacturers of automation, machine and furniture damping components and process technology. In addition, with our individual solutions we are also an important partner for numerous well-known companies in the woodworking and machine tooling technology fields. Award-winning systems and efficient system solutions are the result of decades of experience.

Do you need support with your application in the field of wood and composite materials? We look forward to your inquiry and will be happy to advise you!

Your benefits:

- 3D and circulation-side machining

- Batch size 1 production

- Complete value chain thanks to internal synergies

- Flexible and adaptable thanks to robotics

- Fluid or water-cooled for all areas

- Wide range of applications

Use in the production field

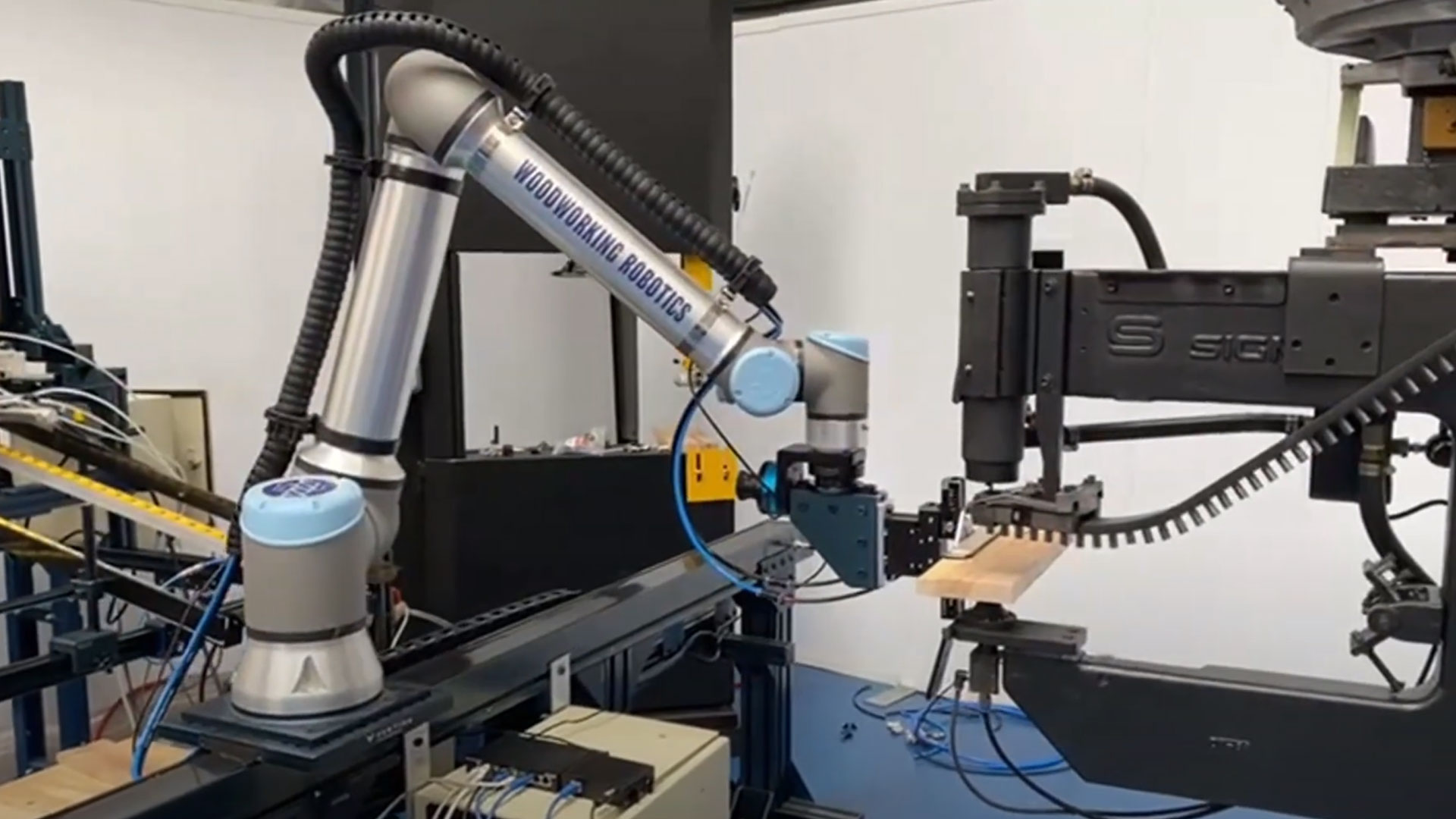

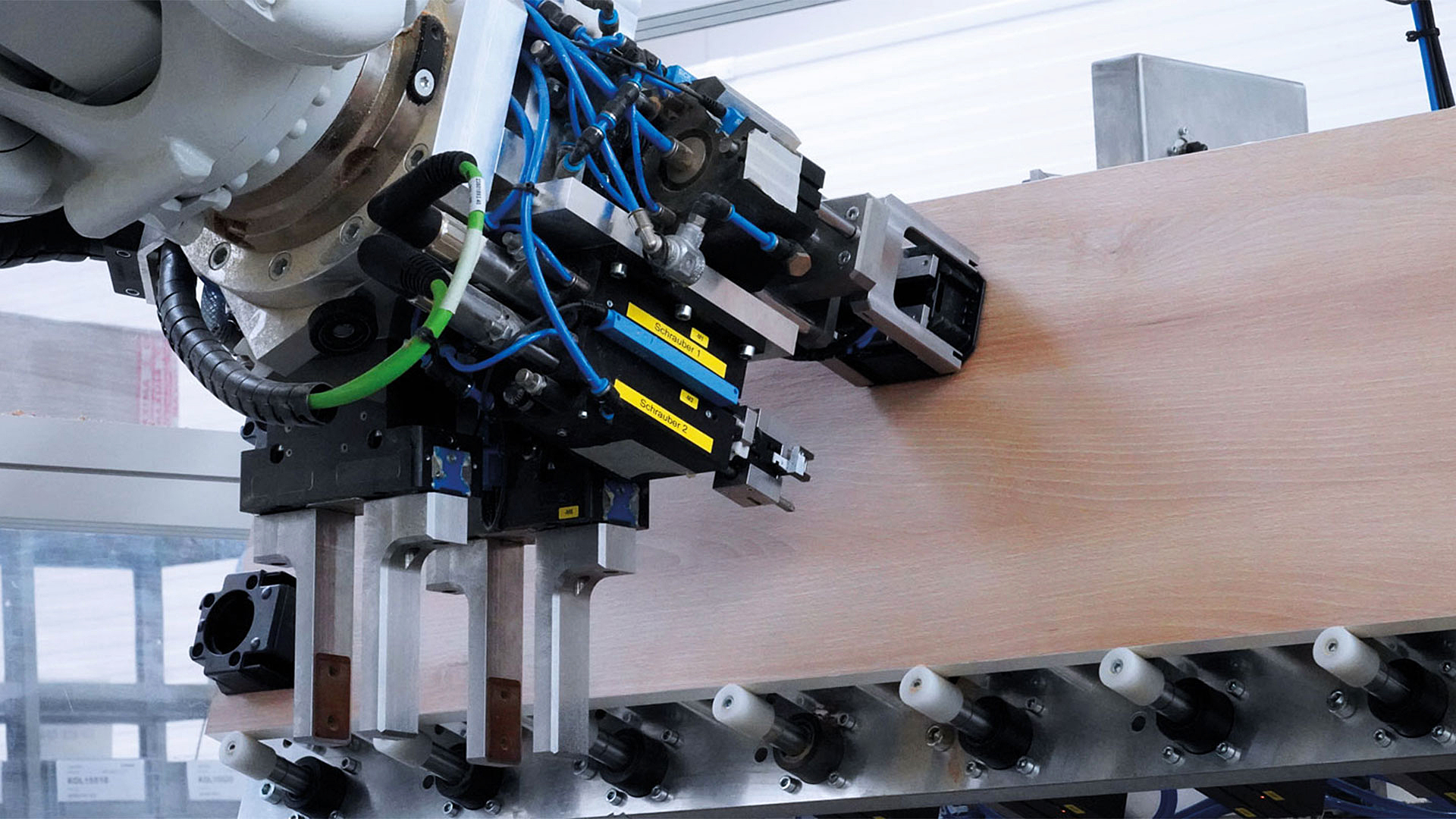

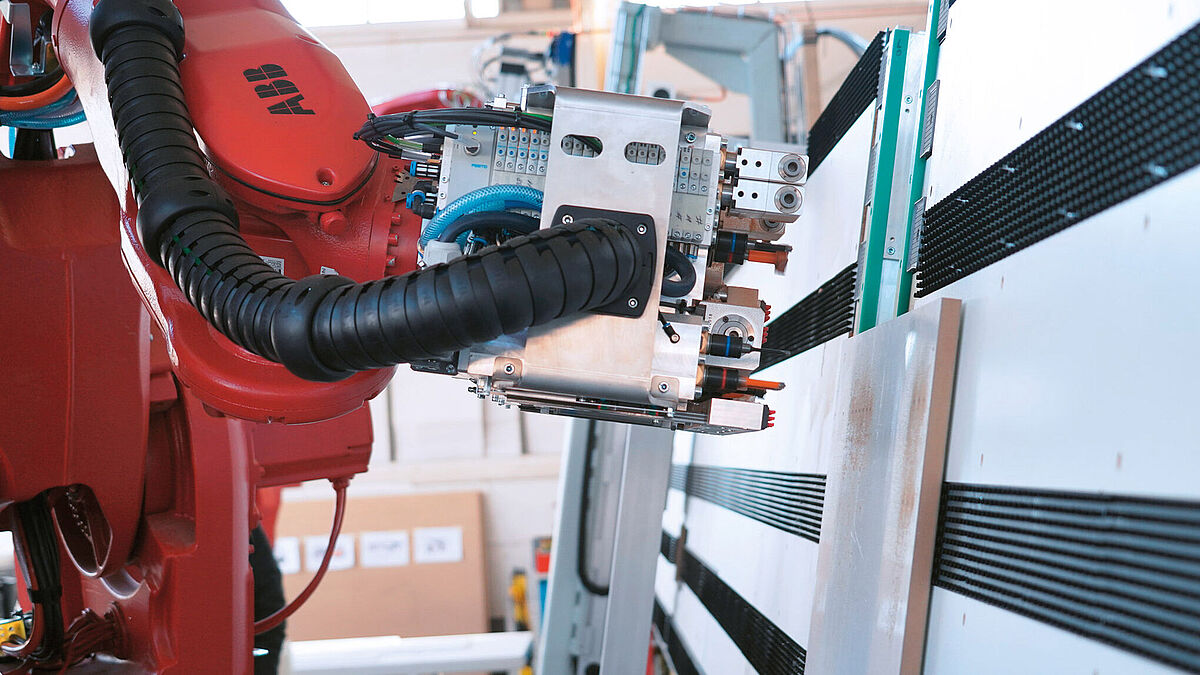

The use of industrial robots is a crucial productivity factor in machine woodworking. The Zimmer Group offers innovative end-of-arm products optimized for the application for the increasing use of robotics. Our intelligent solutions for end-of-arm tooling make crucial contributions to increased productivity. Especially in the age of Industrie 4.0, our mechatronic solutions and the complete range of accompanying digital services open up outstanding opportunities for differentiation.

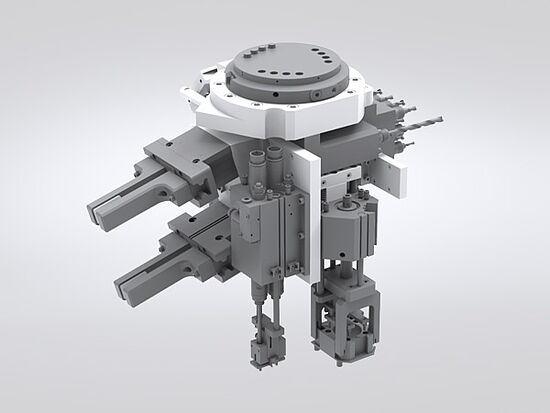

Highly flexible & precise: Body processing/batch size 1

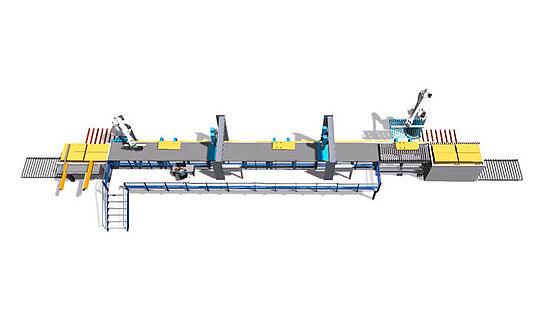

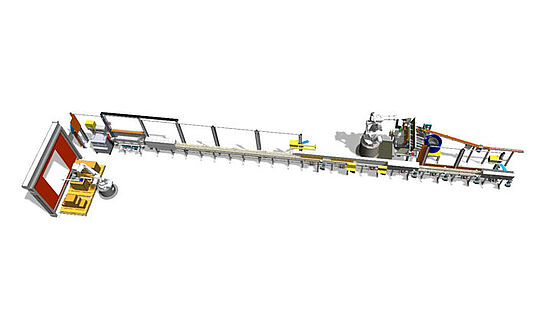

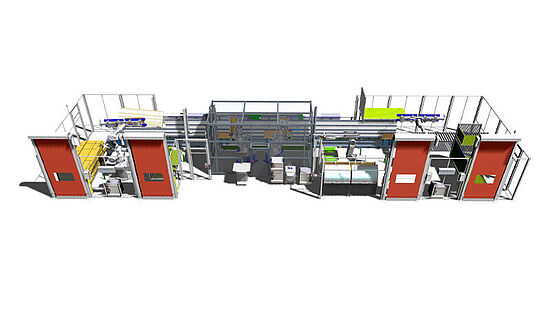

The Zimmer Group worked closely with L’Engineers and the kitchen manufacturer Schmidt Groupe to develop the groundbreaking innovation of robot-assisted drilling for batch size 1 production in the furniture industry. The basic structure of the machine consists of the basic machine with continuous shuttle circulation, a handling robot, a measuring station for precision, processing robots, a fitting robot and a removal robot. The machine control system is directly connected to the higher-level production control system or MES and allows the system to be scaled according to customer requirements.

Example systems

Technical highlights

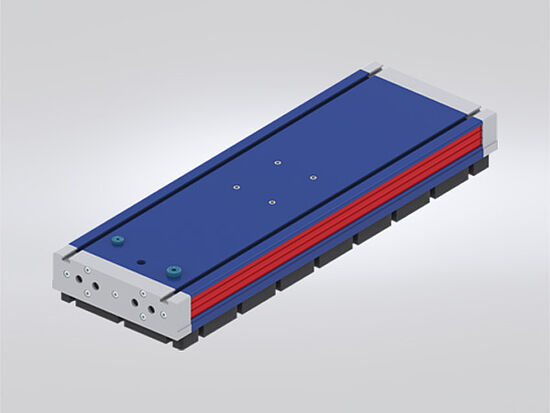

Modular transport system

The transport modules ensure safe, automated workpiece transport within the system. Thanks to its modularity, flexibility and scalability, the systems can be used either as a transport system or a handling system.

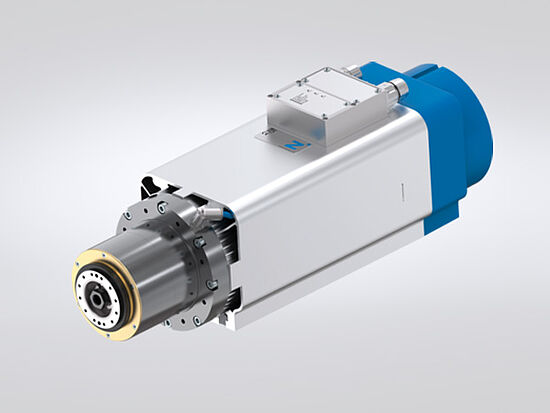

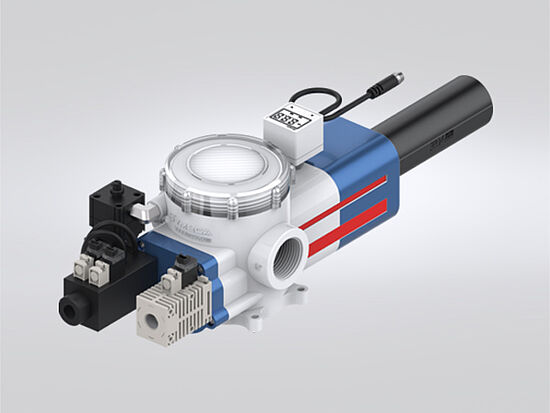

Multifunction unit

The Zimmer Group offers innovative, application-optimized end-of-arm products for the increasing use of robotics in the processing of wood (and wood-like) composite materials. The flexibility knows no bounds.

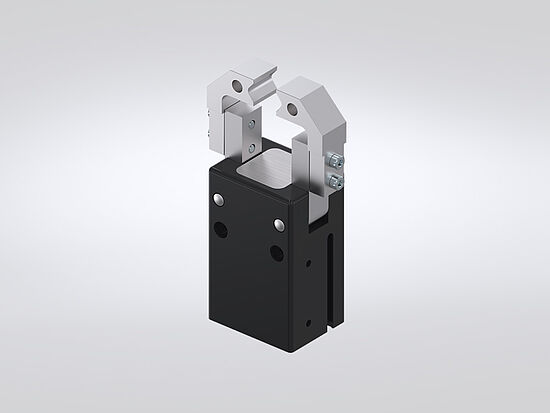

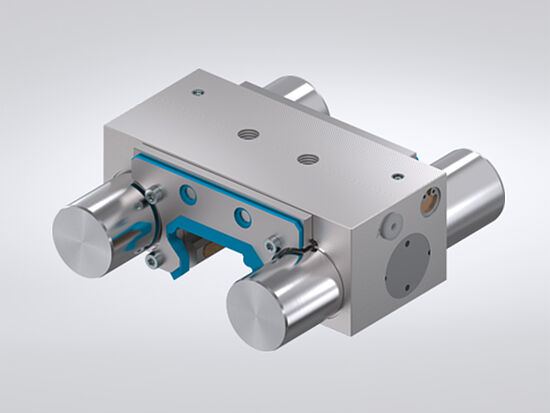

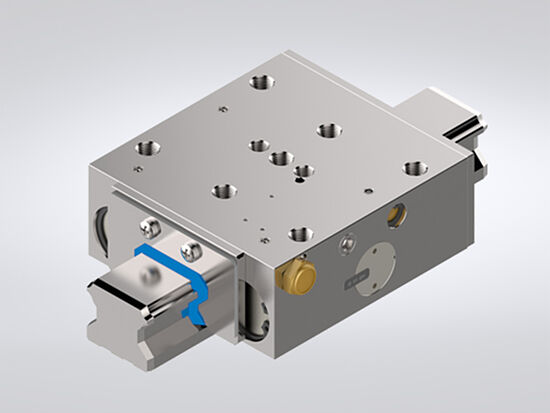

Drilling units with fixed spindles

Customized rigid drilling units in a wide range of variations.

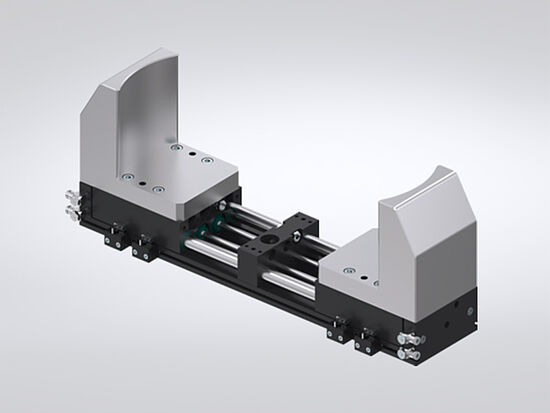

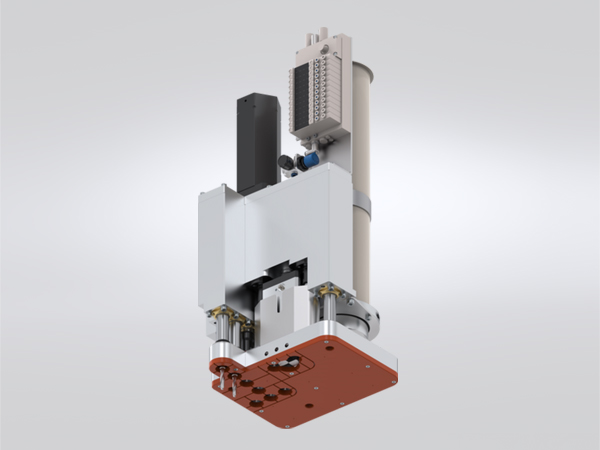

Drilling units with extensible spindles

Customized adjustable drilling units in a wide range of variations.