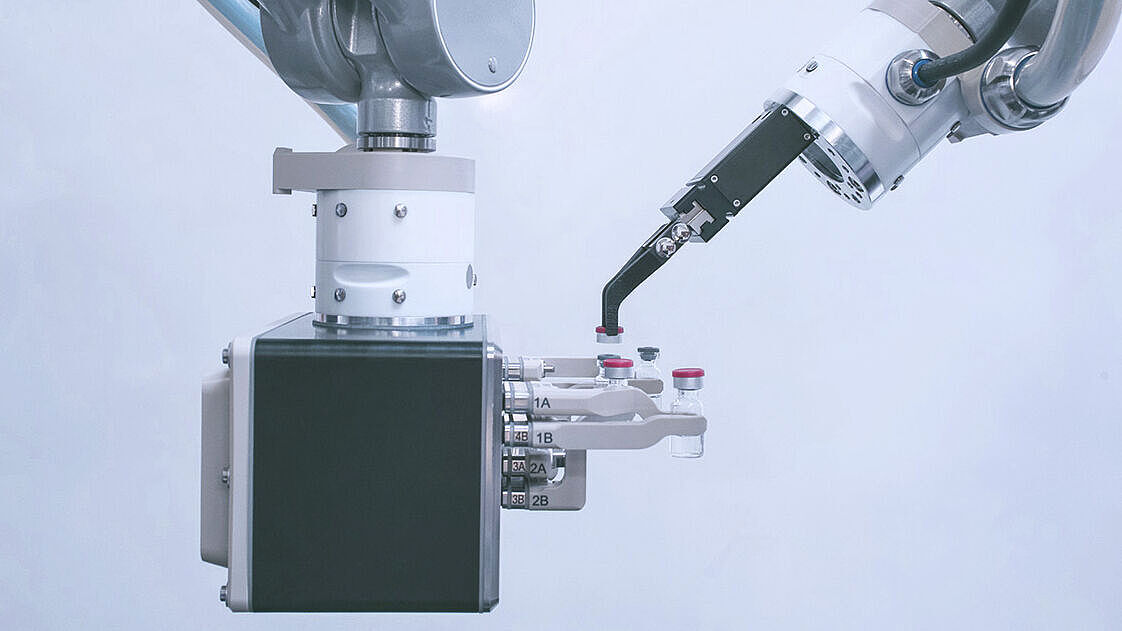

Tool changer for the pharmaceutical industry

Developed for the highest hygiene requirements

In no other field are uncompromising safety, absolute precision and maximum hygiene as crucial as in the laboratory and medical industry. To meet these requirements, the Zimmer Group has developed an aseptic tool changer. In addition to its lightweight design, this innovative tool changer from the WMR2000 series offers numerous other advantages and lays the foundation for flexible, efficient and safe automation solutions in the pharmaceutical sector: clean room certification, IP protection class, hygienic design and flexibility in the choice of end effectors. Discover the advantages of the WMR2000 series and find out how these robotics can be used to implement glove-free process steps in the laboratory!

Your benefits at a glance:

Permanent electromagnet: Ensures a secure hold.

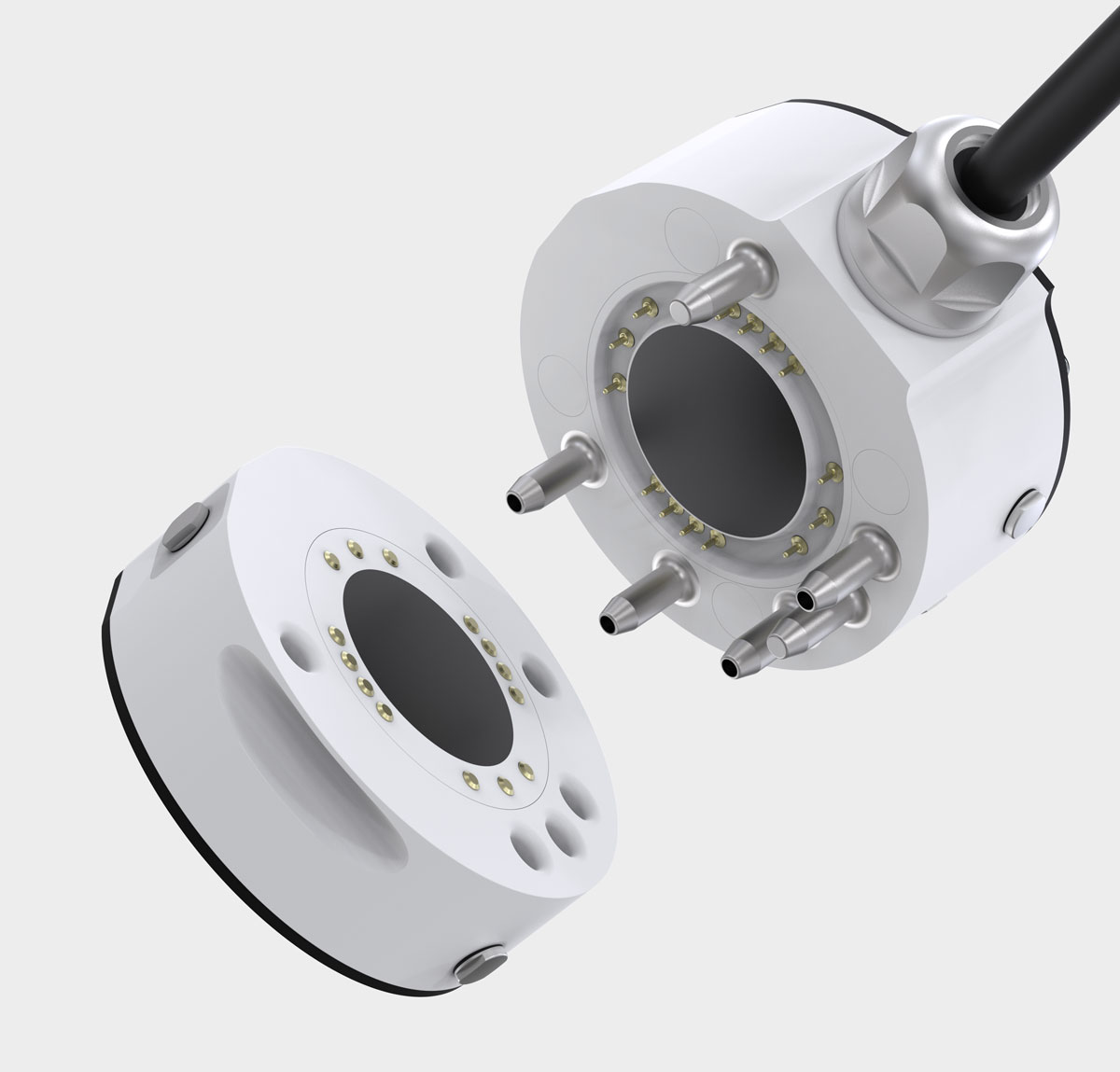

Integrated media transfer: Up to four integrated pneumatic or vacuum transmitters.

Resistant materials: Construction in accordance with GMP and ISO 14644 with FDA-compliant materials.

Optimized signal transmission and resistant materials

The reliable tool changer for laboratories and similar.

SECURE HOLD

In the NC version, the permanent electromagnet ensures a secure hold even in case of a power outage.

Secure signal transmission

In addition to up to four integrated compressed air/vacuum transmitters, specially developed sealed spring pins ensure secure signal transmission.

Safe materials

The tool changer is made of FDA-compliant, durable materials that guarantee resistance to aggressive cleaning agents such as hydrogen peroxide.

Focus: Smooth processes in the laboratory

Automated processes in the pharmaceutical industry are complex and demanding. Particularly in aseptic environments, as is often the case in laboratories, the machines must offer maximum precision and reliability. Conventional systems often reach their limits here. Find out which problems the WMR2000 series tool changer solves in laboratory processes in our user report.