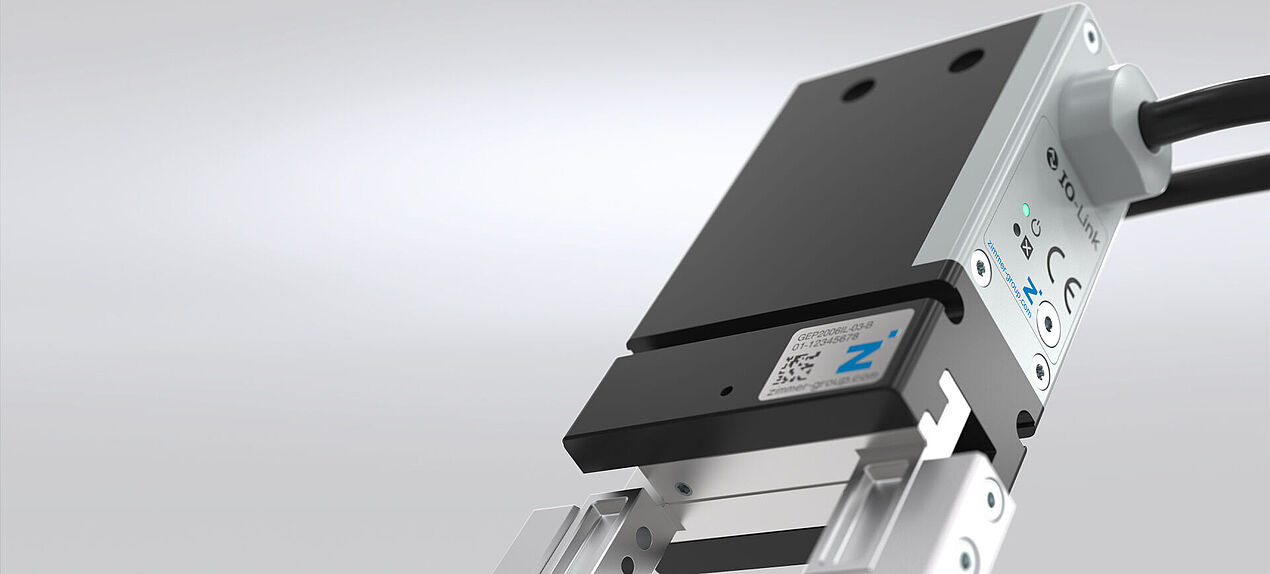

SMALL PARTS GRIPPERS OF THE HIGHEST CLASS: GEP2000

Do you need a reliable, intelligent electronic gripper for small parts? Then the GEP2000 series is just right for you! The standard equipment with mechanical self-locking mechanism and IO-Link connection offers you safety in your process flow and uncomplicated integration into your system. Certified with clean room class 2, we guarantee minimal particle emissions, which makes the grippers ideal for use in the pharmaceuticals or electrical industry. Automatic part detection, protector equipment and flexible positioning set new standards among electric grippers. See the benefits of the GEP2000 series for yourself!

GEP2000 gripper series

Electric, compact and with a long stroke. If you need a gripper that combines these features, the GEP2000 series is the right choice for you. See the advantages for yourself:

- Flexible positioning thanks to IO-Link connection

- Up to 10 million maintenance-free cycles

- Largest stroke in a small installation space

- Self-locking mechanism for greater safety in the production process

- Easy integration into your control system

Mechanical self-locking mechanism

The standard equipment with mechanical self-locking on the GEP2000 series grippers ensures that workpieces are held securely in the gripper at all times. Even in the event of a power failure or emergency stop, the risk of injury to employees or damage to workpieces and the system is minimized.

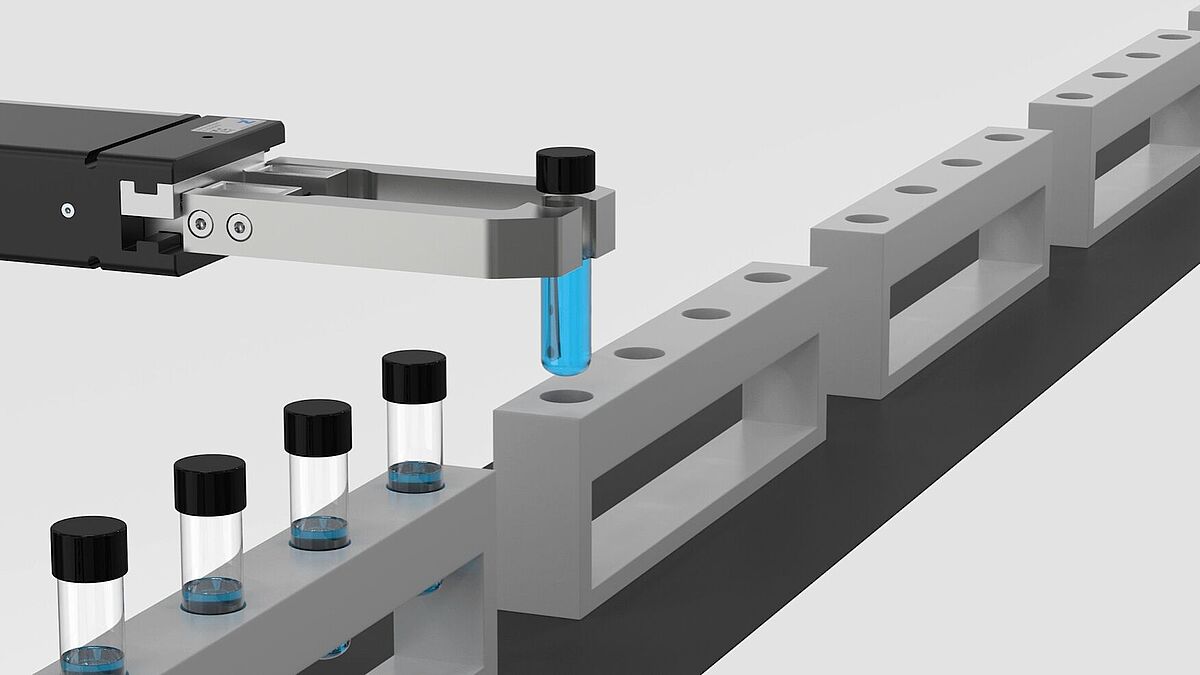

Automatic part detection

The grippers in the GEP2000 series actively support you in quality assurance: The standard values for your workpieces, including tolerances, can be stored in the gripper. Thanks to the integrated automatic part recognition, deviations in the product are immediately detected by the gripper. They can be sorted out immediately.

Clean room class 2

Having earned Class 2 clean room certification in accordance with DIN EN ISO 14644, the GEP2000 guarantees low particle emissions and therefore is ideally suited for use under increased hygiene requirements and in clean rooms such as those in the pharmaceuticals or electronics industry.

Protected from splash water

In order to meet the diverse requirements of a wide range of applications, the 2000 series grippers are equipped with wipers on the top cover and have the increased protection class IP54. Perfect protection against external influences such as spray water and small dust particles. In addition, the sealed guides and food-safe H1 grease are ideal for use in the food industry. The covers and screws are made of stainless steel, which makes cleaning easier and protects the grippers from corrosion damage.

IO-Link connection

The integrated IO-Link connection guarantees the simplest implementation in your communication. With IO-Link as the transmission technology, your system is prepared for the requirements of the world of Industrie 4.0. This opens up a number of advantages for you: flexible positioning, uncomplicated control, avoidance of interference contours. IO-Link also allows integrated querying.

Simple integration of IO-Link grippers into your PLC environment – click here for our step-by-step guide:

SMART COMMUNICATION MODULES

- Translates IO-Link to digital inputs and outputs (Digital I/O), as well as from Digital I/O to IO-Link

- Very easy control of intelligent IO-Link grippers via 24 V digital I/O

- Configuration and training is done with the associated intuitive guideZ software

- Can be used with one or two grippers, depending on the required flexibility

- Up to 15 different workpieces can be taught in for one gripper

Products

SYSTEMS

In addition to our standard gripper components, we also offer customized system solutions – from specification to implementation – to meet your specific requirements. By using our proven modules, we specialize in offering high-quality solutions at competitive prices. We offer ready-to-connect system solutions for your applications and have a wide variety of modules in our portfolio. These are very easy to adjust and configure and can be conveniently adapted to your particular application. Our proven system solutions, of which more than 9,000 are already in use on the global market, have a long service life with minimal maintenance requirements and are also Industrie 4.0-capable!