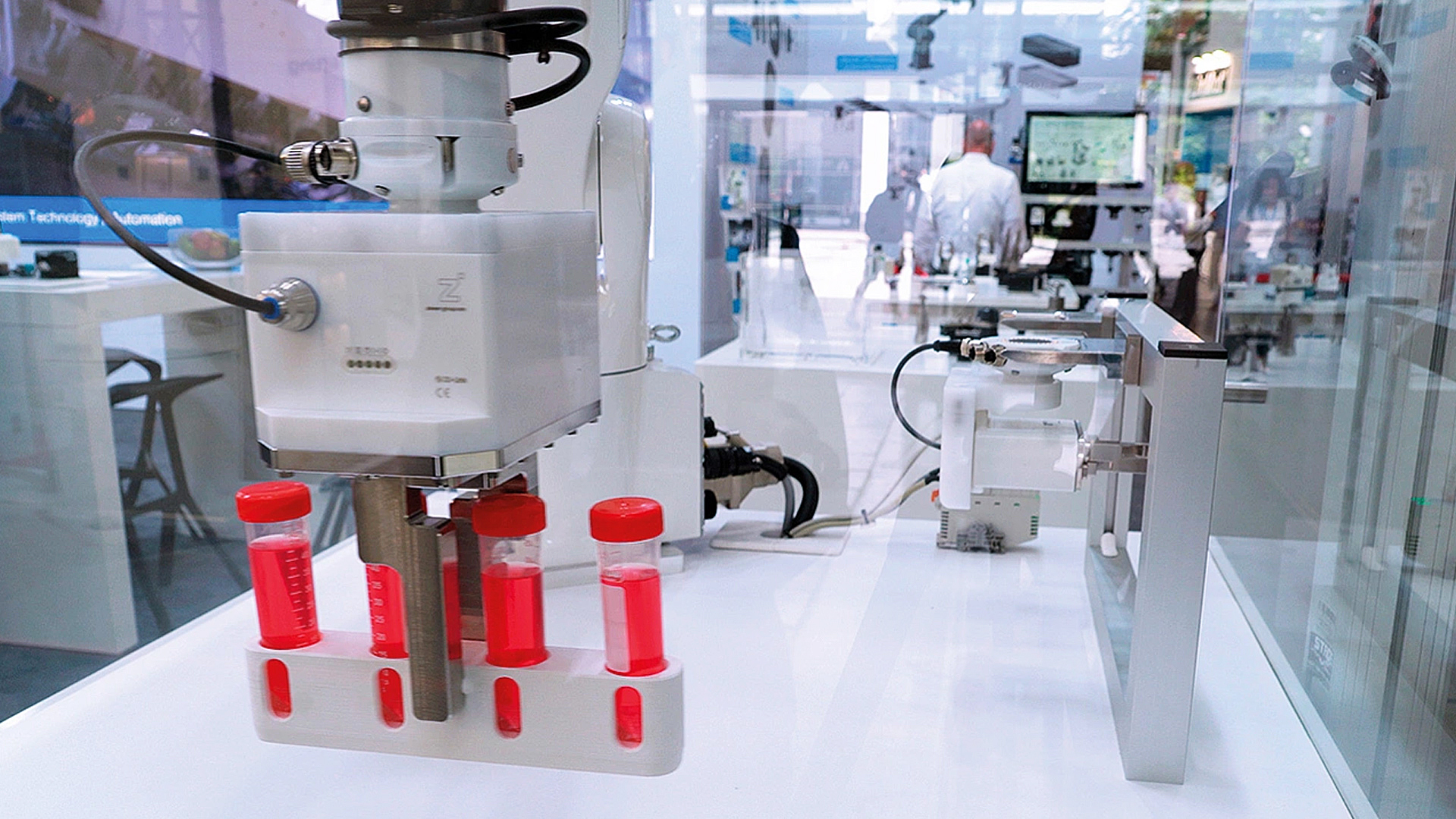

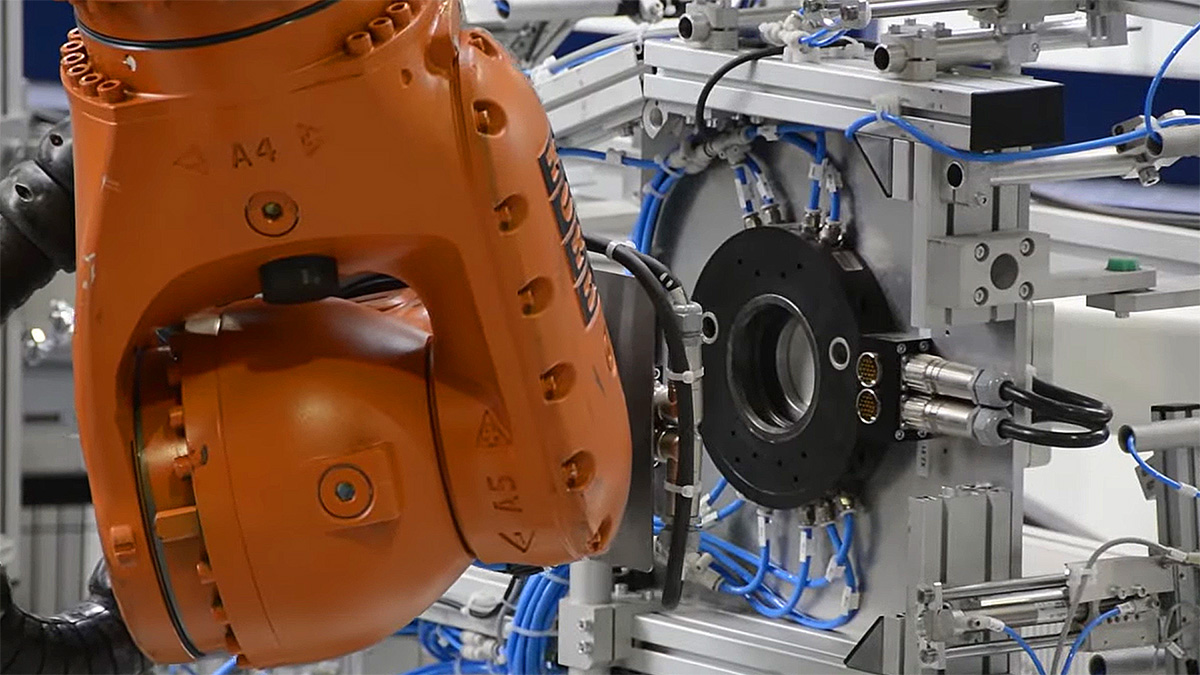

Tool changers

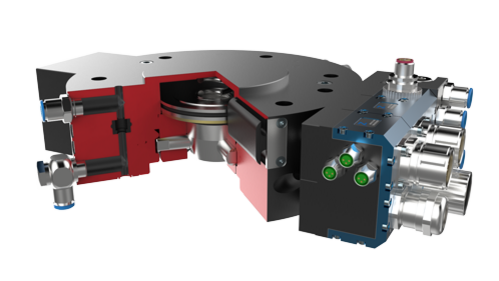

Our tool changers offer you the perfect solution to maximize the flexibility and productivity of your manufacturing processes. Developed for maximum precision and durability, they allow quick and safe switching between different tools. From compact systems to highly complex models for industrial applications – we have the right tool changer for your individual requirements. Browse through our selection and discover the variety of our innovative products that will make your production processes more efficient and increase your competitiveness.

Robot Accessories

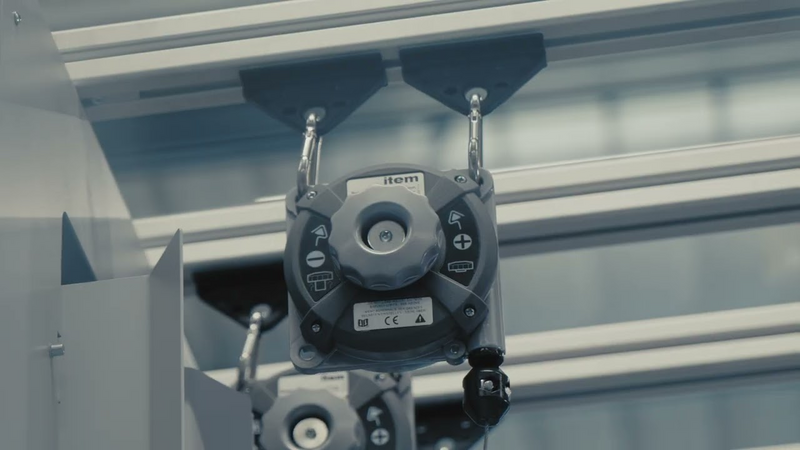

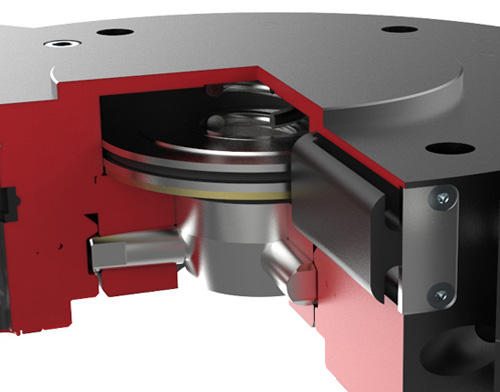

- Secure hold during pressure drop: A redundant system, created by the combination of spring accumulator and a self locking mechanism, guarantees a safe machine

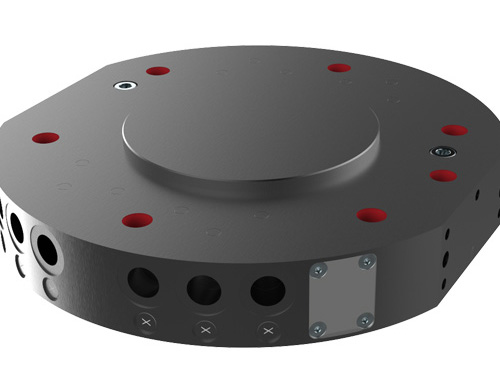

- Extremely flat design: This structure reduces the moment load for your robot to a minimum and makes it possible to use smaller and more affordable sizes

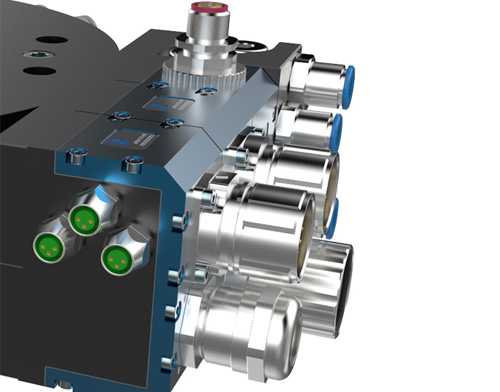

- Inexhaustible variety of media transfer systems: No matter which medium you would like to transmit, we will draw from our wealth of experience in implementing projects and find a solution to suit your needs!

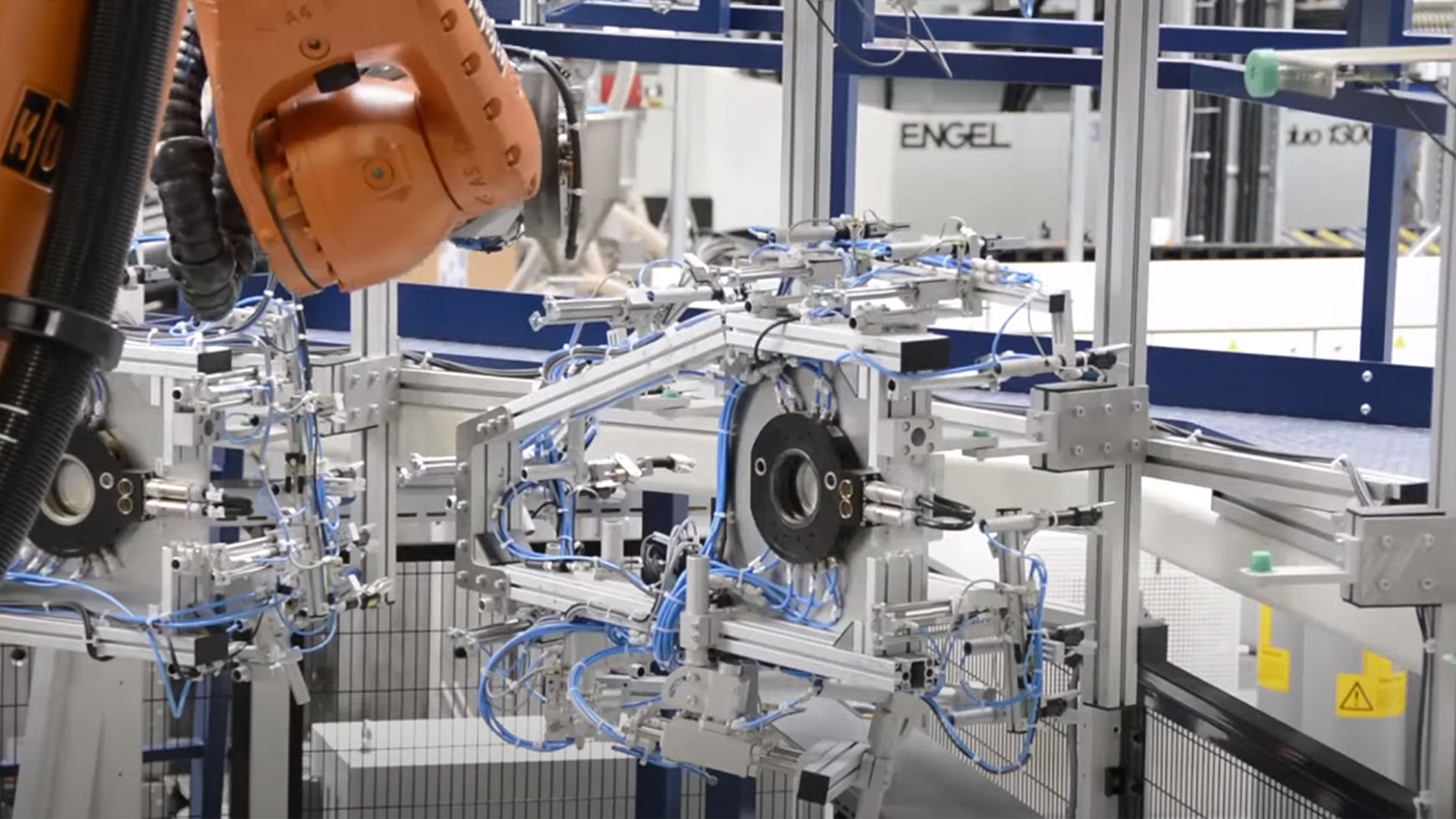

VARIETY

Do you want to custom-build your machine and have freedom in media transmission? Working with us allows you to select from a wide variety of standardized energy elements. We are also experienced to develop a custom solution for you.

STANDARDIZED

The height of the structure reduces the load capacity of your robot. That is why our robotic components form structures with minimal height and can be combined together without additional adapter plates. Direct mounting onto the robot takes place using the mounting flange in accordance with EN ISO 9409-1.

SAFE

Production safety is a priority for us. That is why our tool changers offer you maximum reliability, with the integrated sensor technology, the spring installed for maintaining force and the extremely robust, line contacting locking bolts.

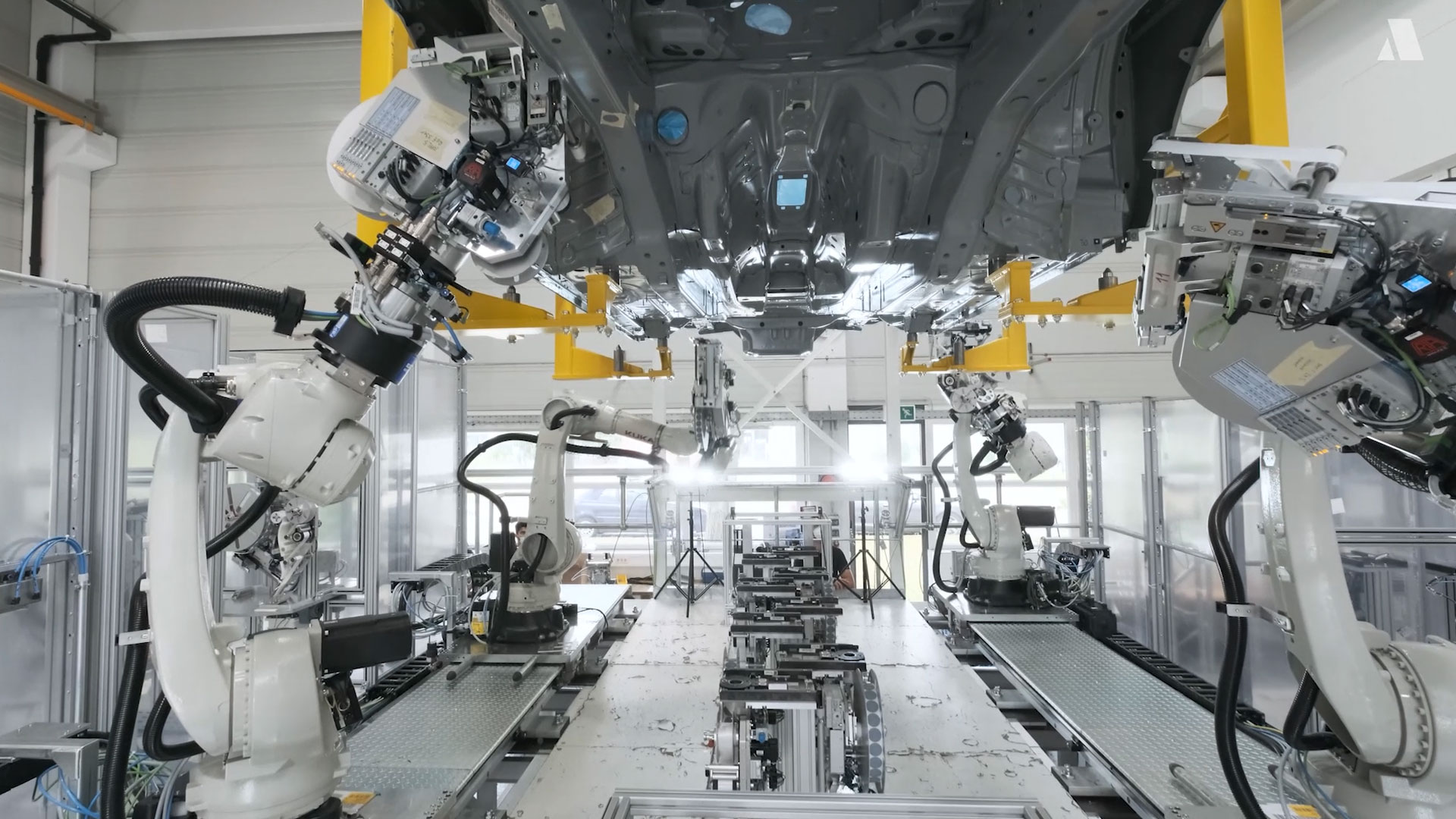

Focus: The importance of tool changers

Tool changers play a crucial role in robotics. Find out more about what’s going on behind the scenes and why tool changers should not be underestimated as a key element of full automation.