Dynamic and flexible for the automotive industry

Innovative, flexible, powerful and cost-effective – these are the requirements that the modern automotive industry places on its production processes and systems. Requirements that must also be met by the components, assemblies and systems used in production and assembly systems.

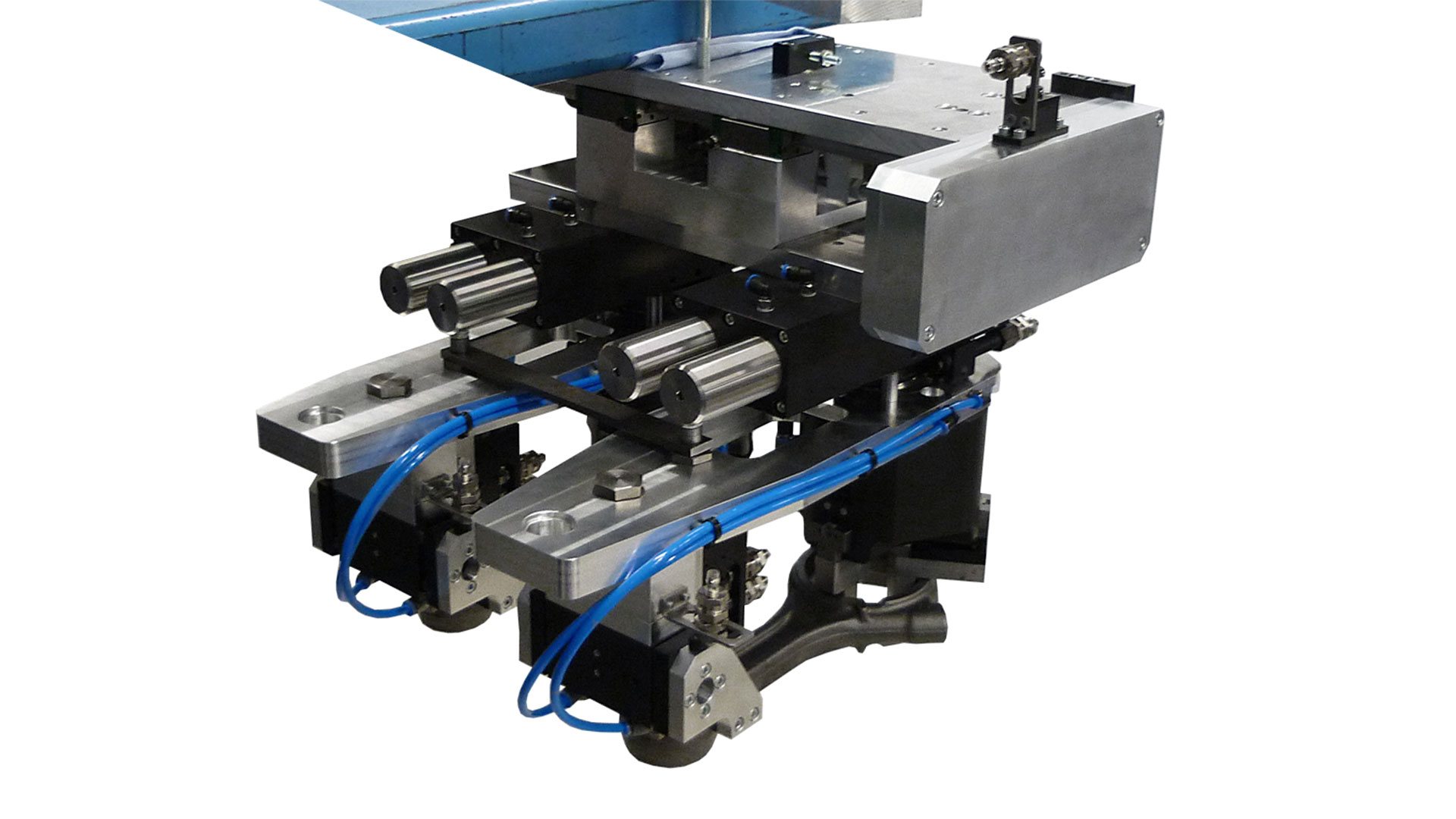

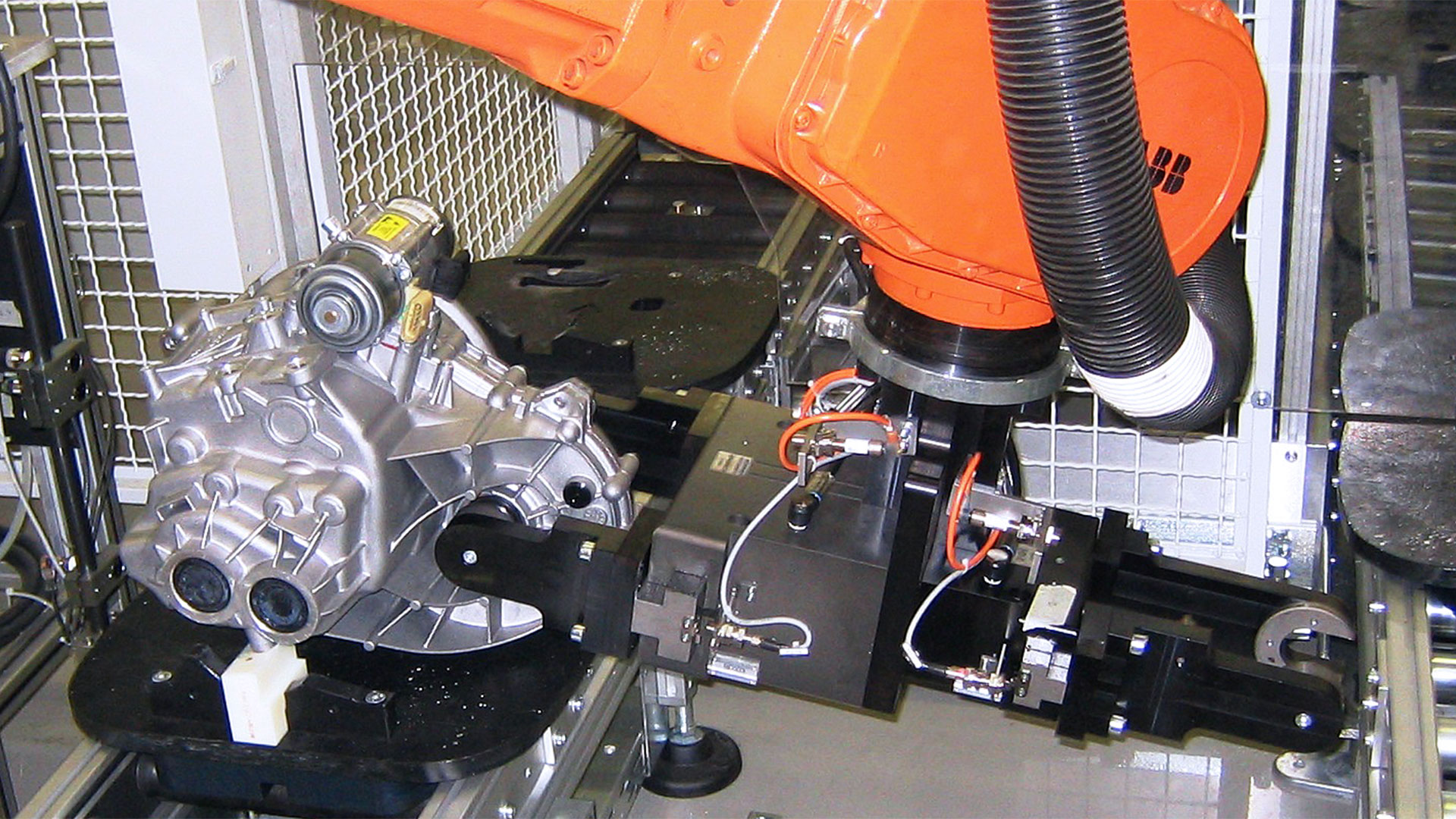

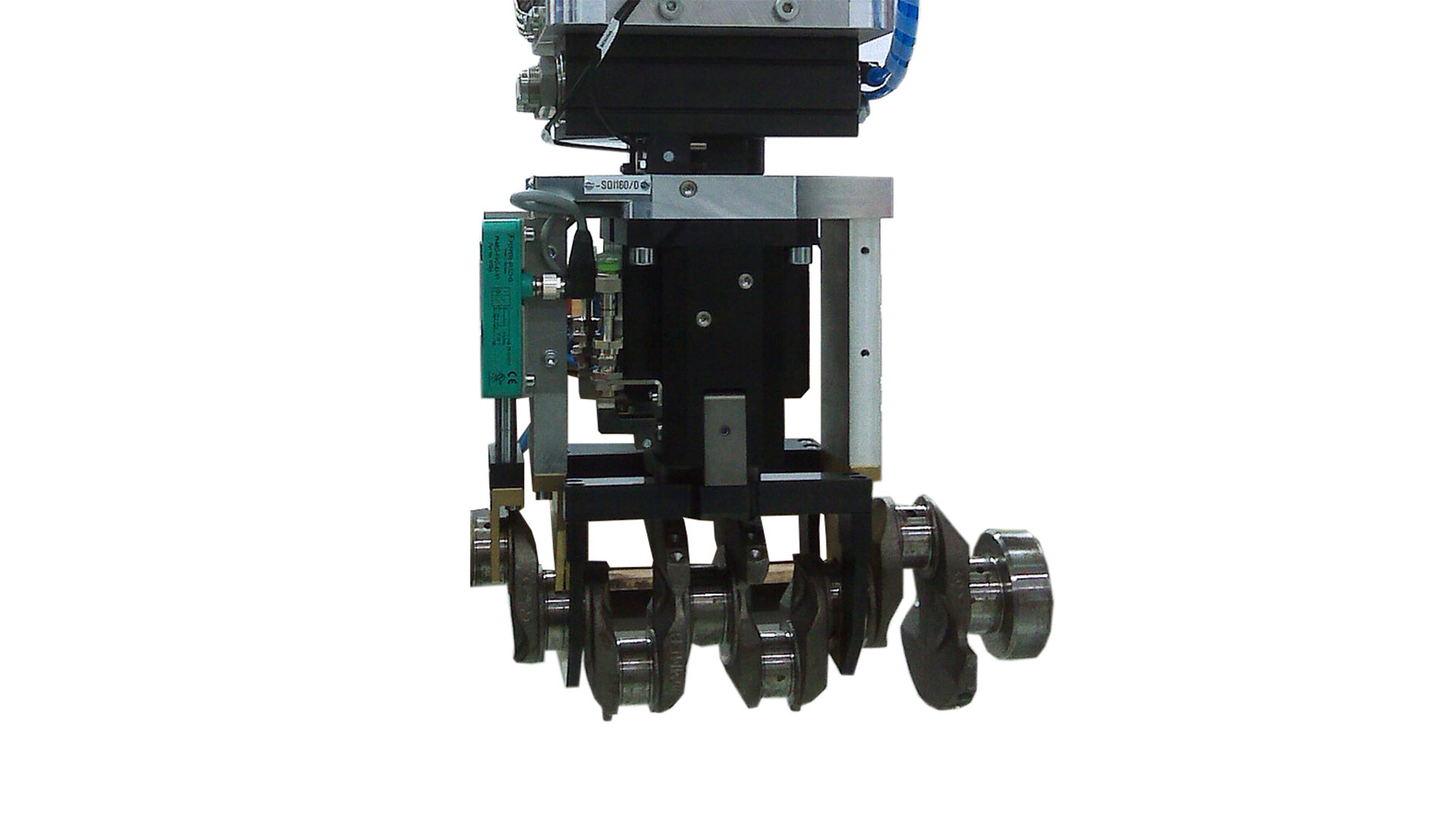

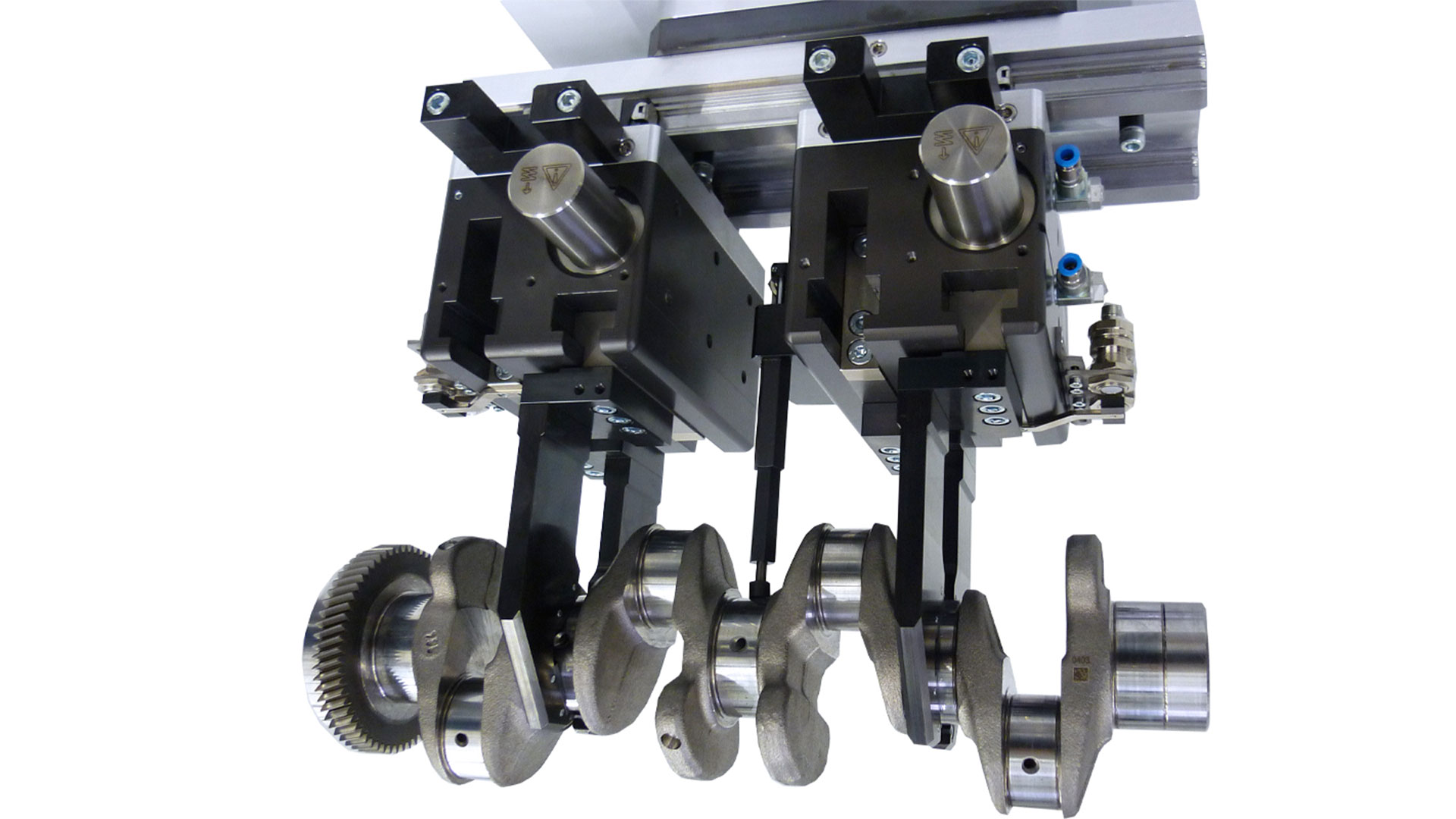

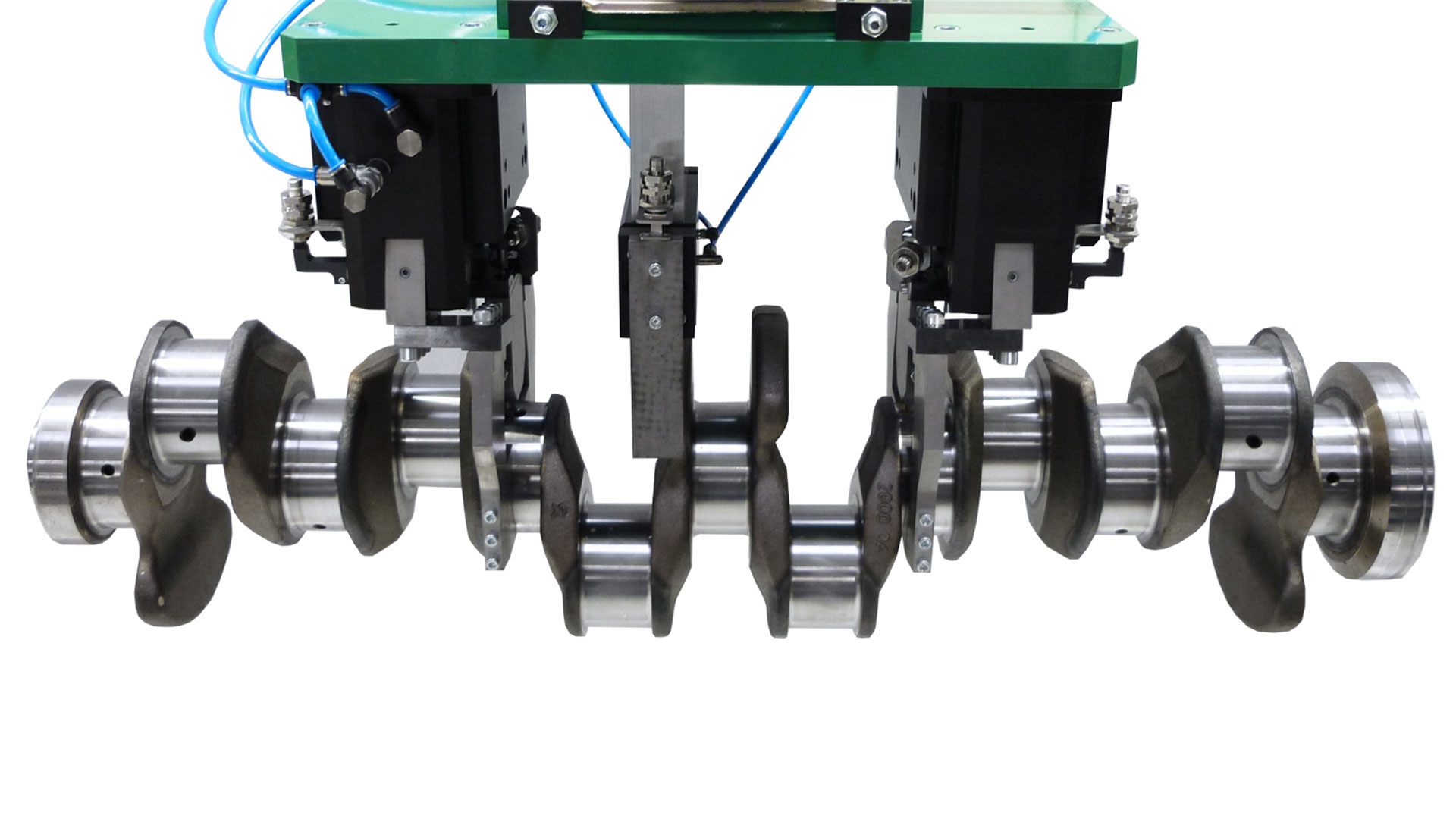

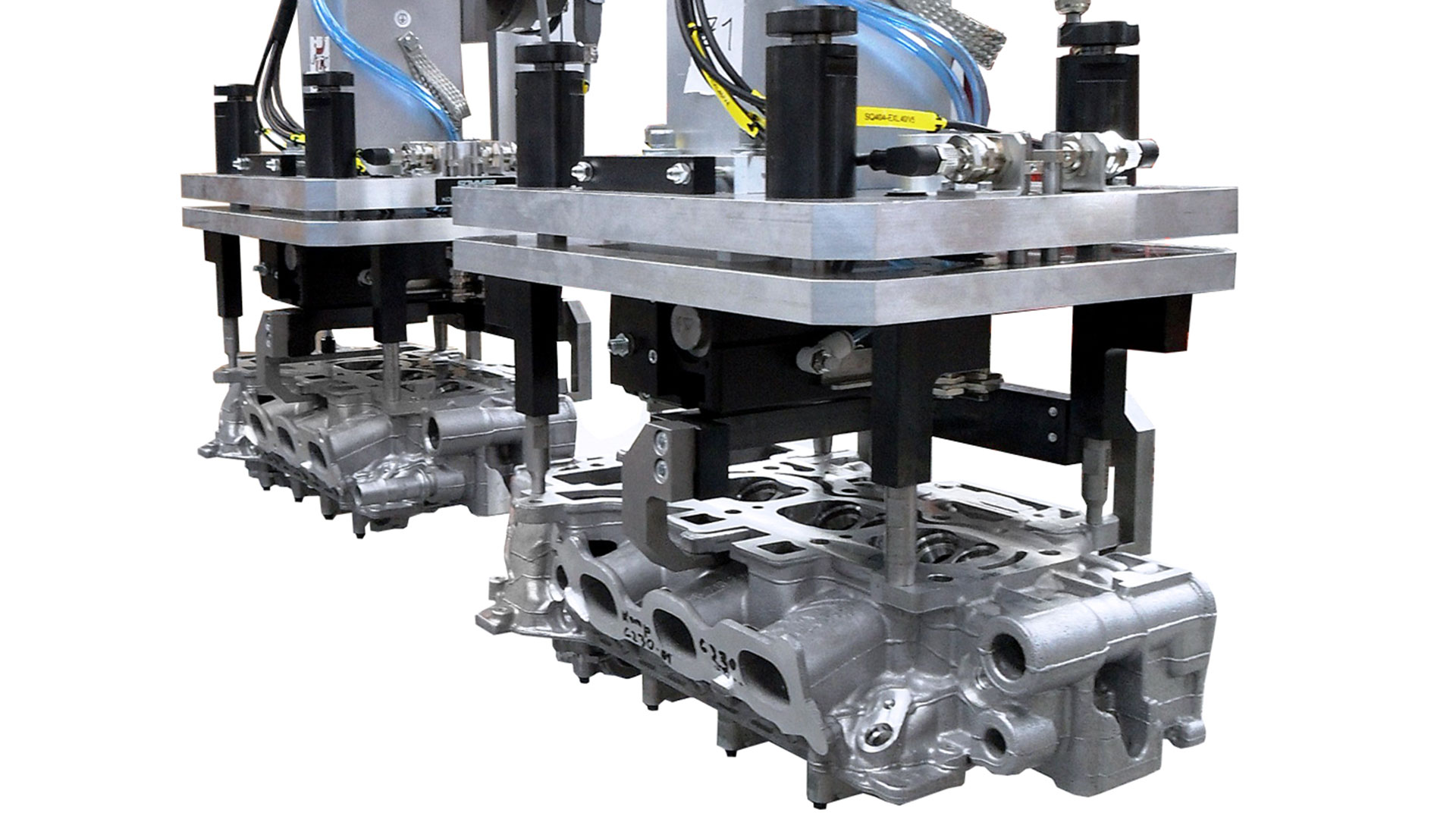

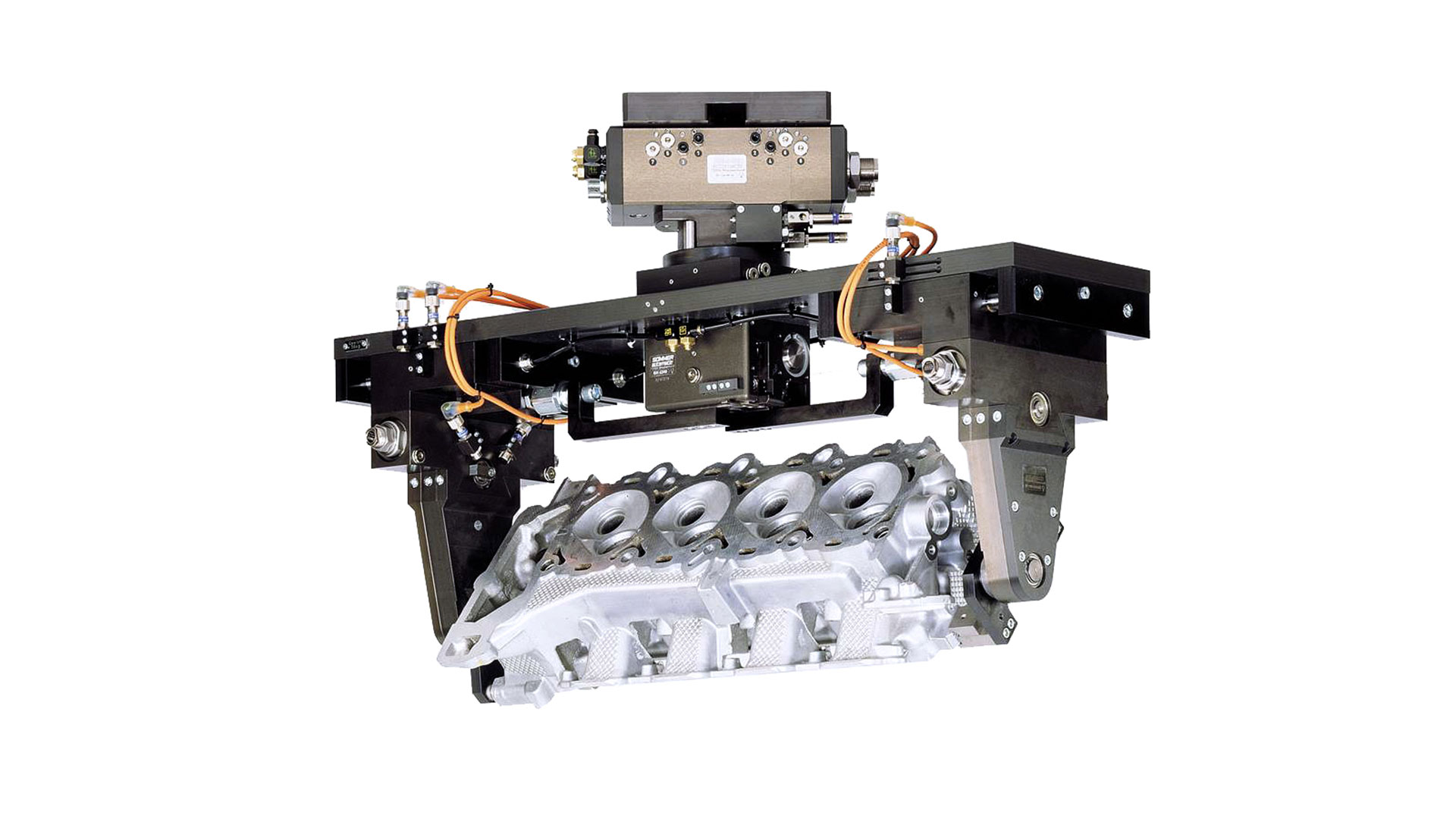

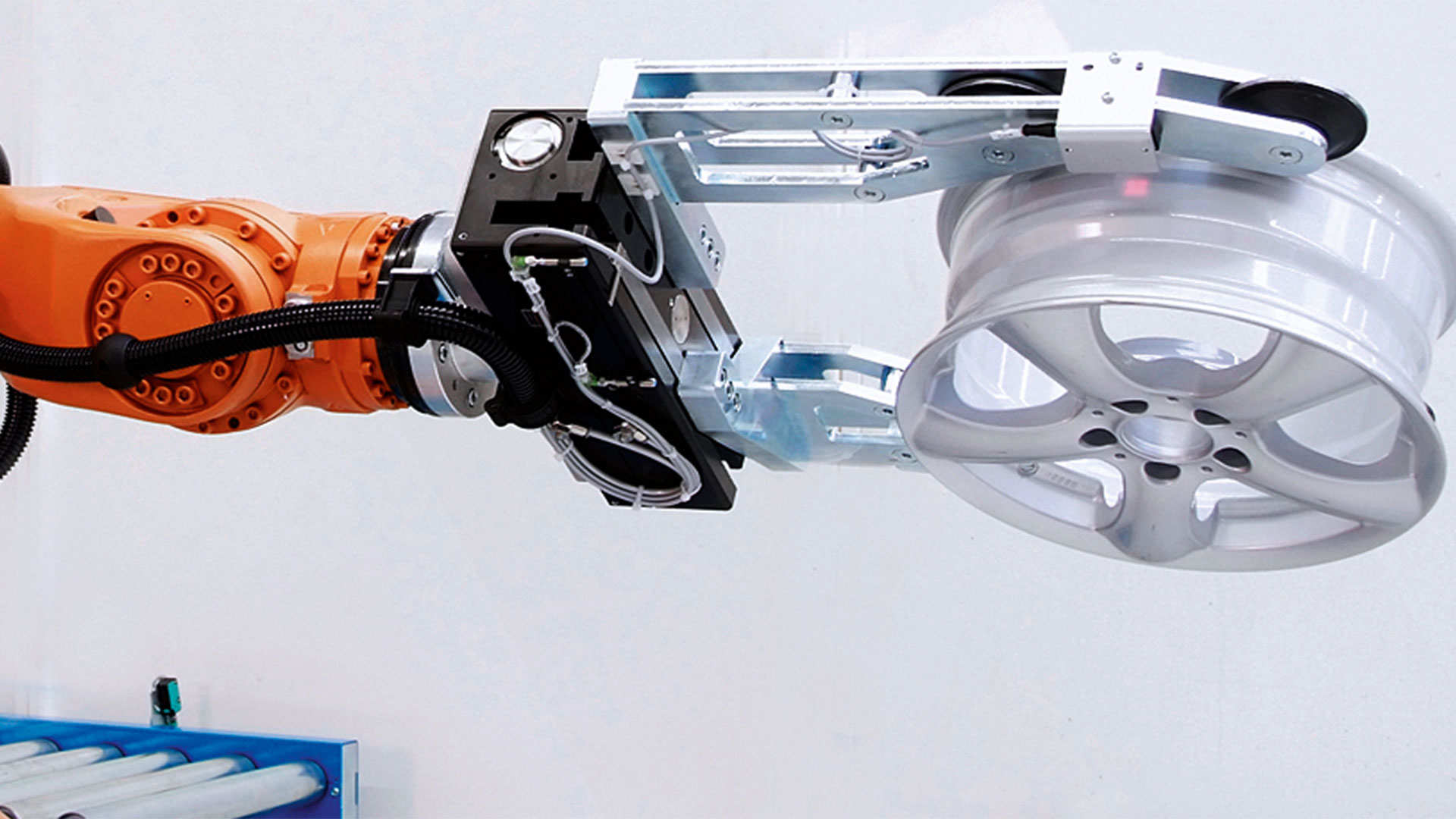

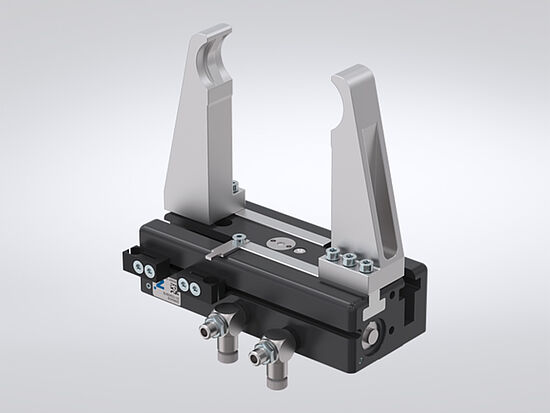

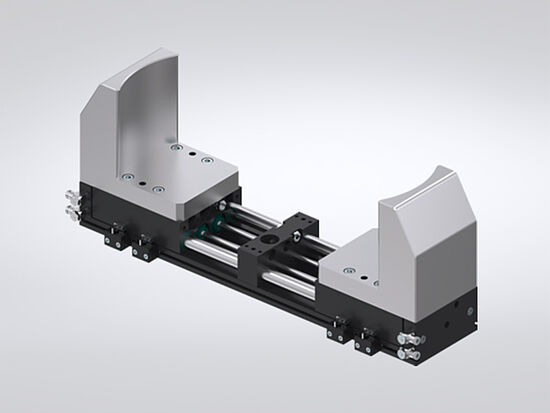

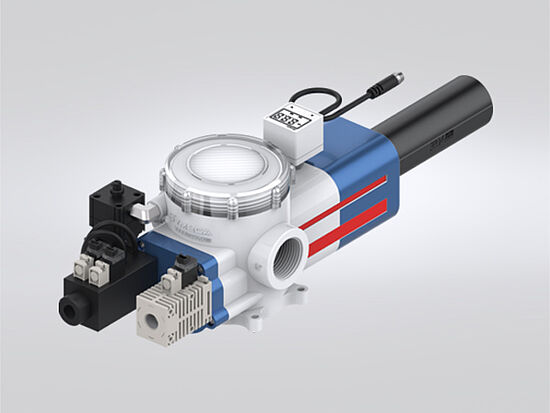

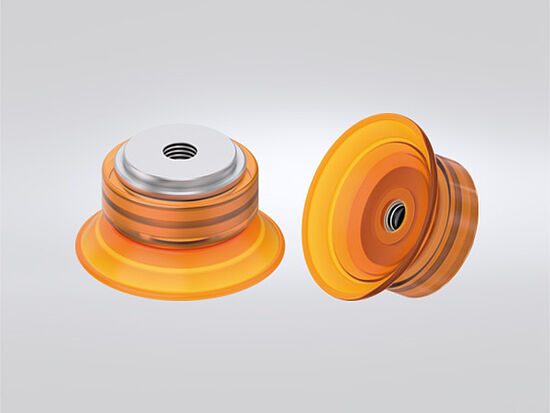

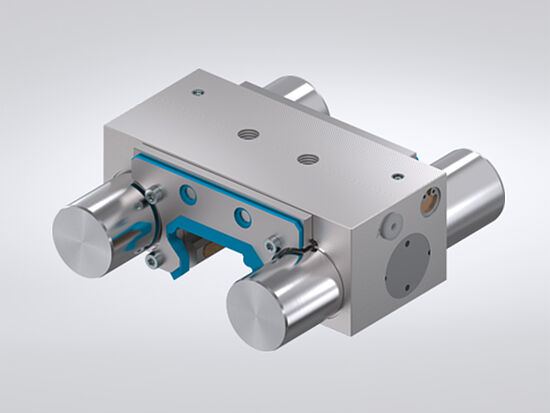

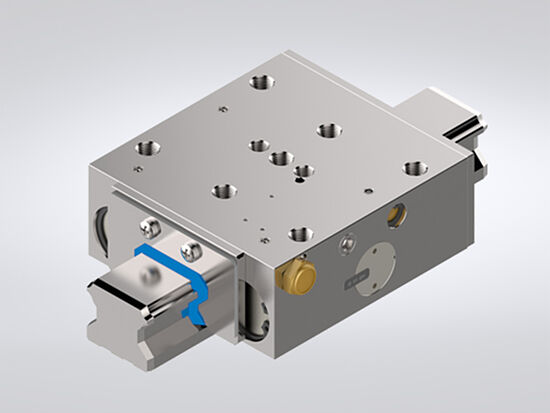

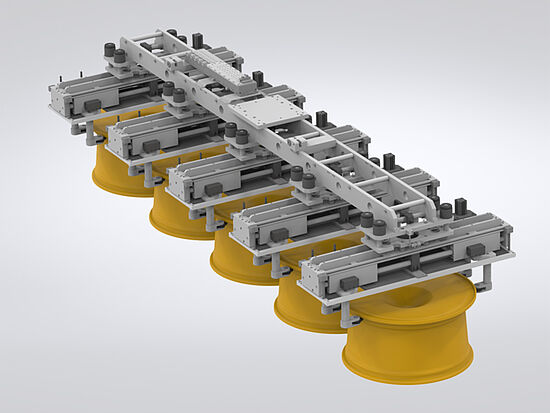

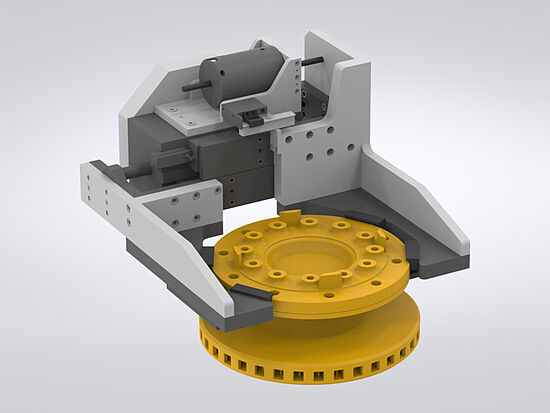

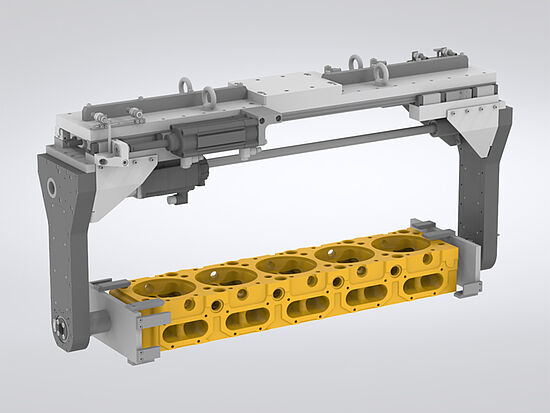

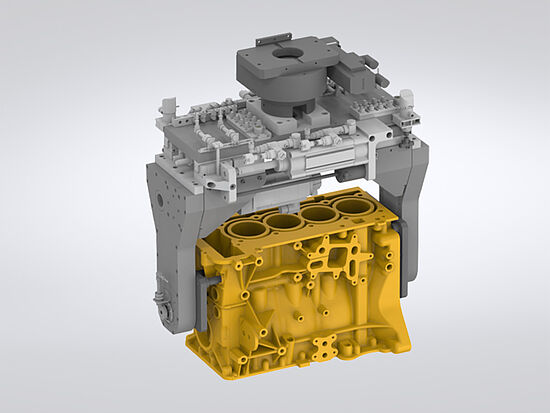

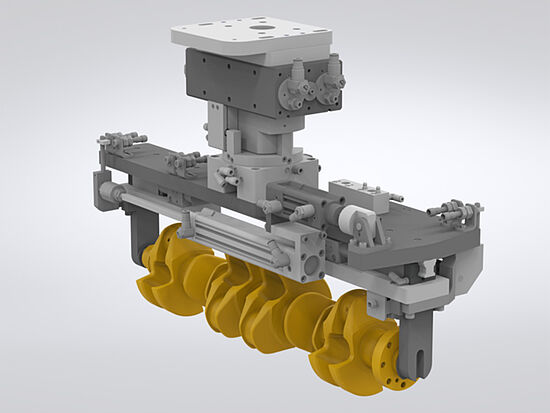

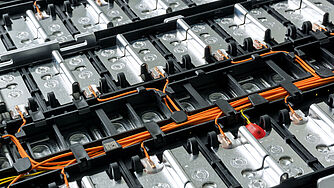

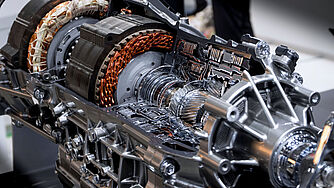

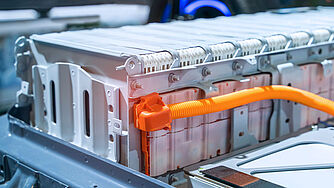

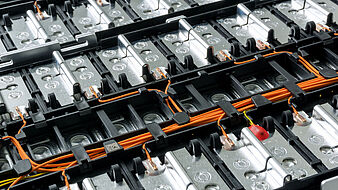

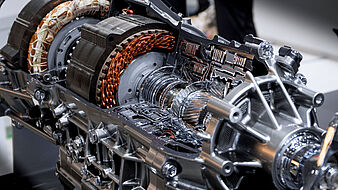

We know these requirements. We have been a partner to renowned automotive manufacturers, suppliers and their plant manufacturers for over 40 years. The Zimmer Group offers standardized automation components and systems for every required function, including gripping, swiveling, turning, clamping, braking, damping or tensioning. It doesn’t matter which automotive product you want to handle. Exterior, interior, body, chassis or drive, crankshafts, camshafts, stator, rotor or battery pack – we have the right automation.

Have we piqued your interest? We look forward to your inquiry and will be happy to advise you!

Your benefits:

- Decades of experience, expert knowledge and development expertise in the automotive sector

- Standardized components offer maximum functionality and service life

- Suitable for use in the most adverse environmental conditions

- Individual solutions for maximum process reliability and maximum productivity

- Comprehensive product portfolio for all applications in your value chain

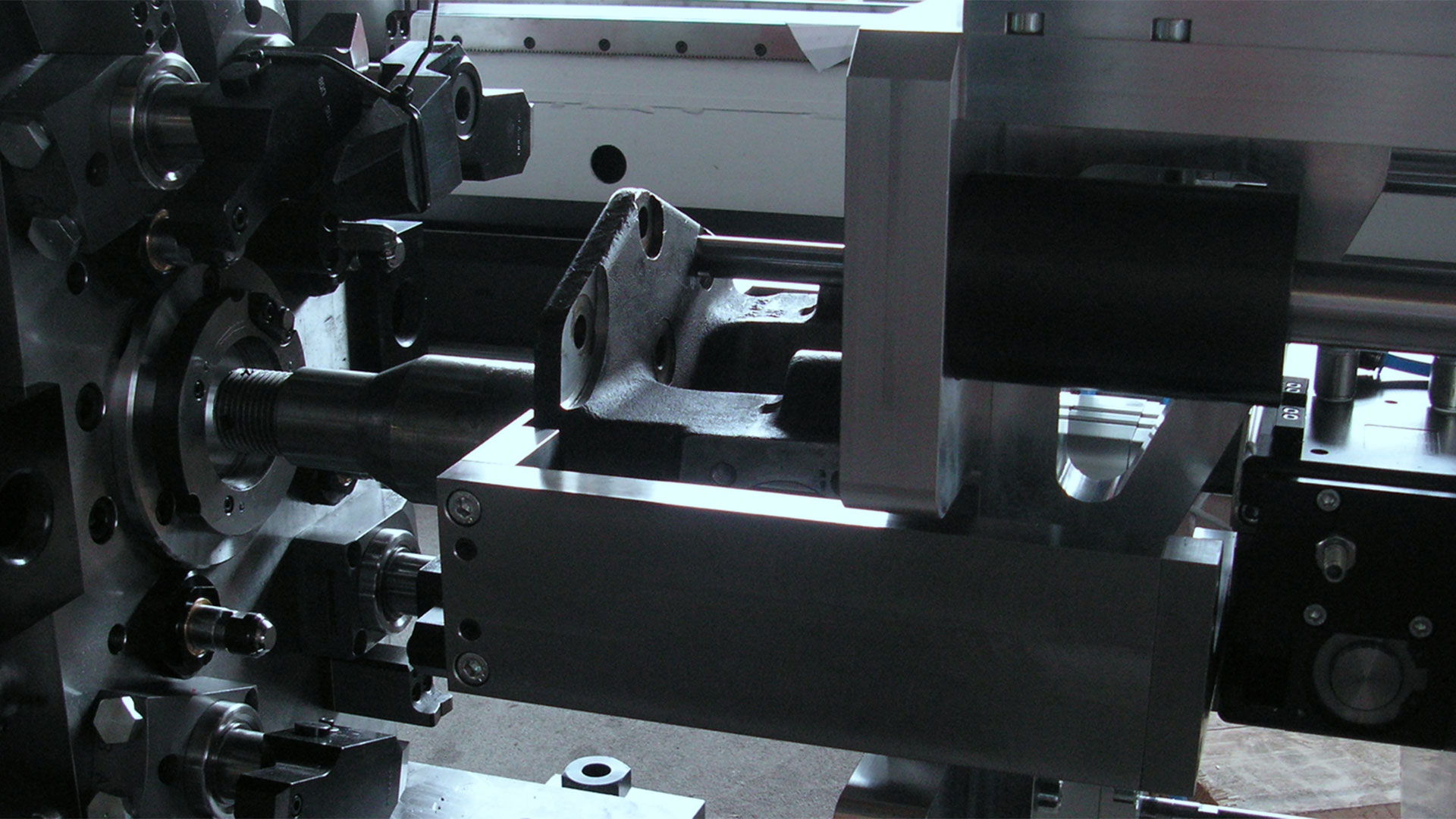

Components for automotive production

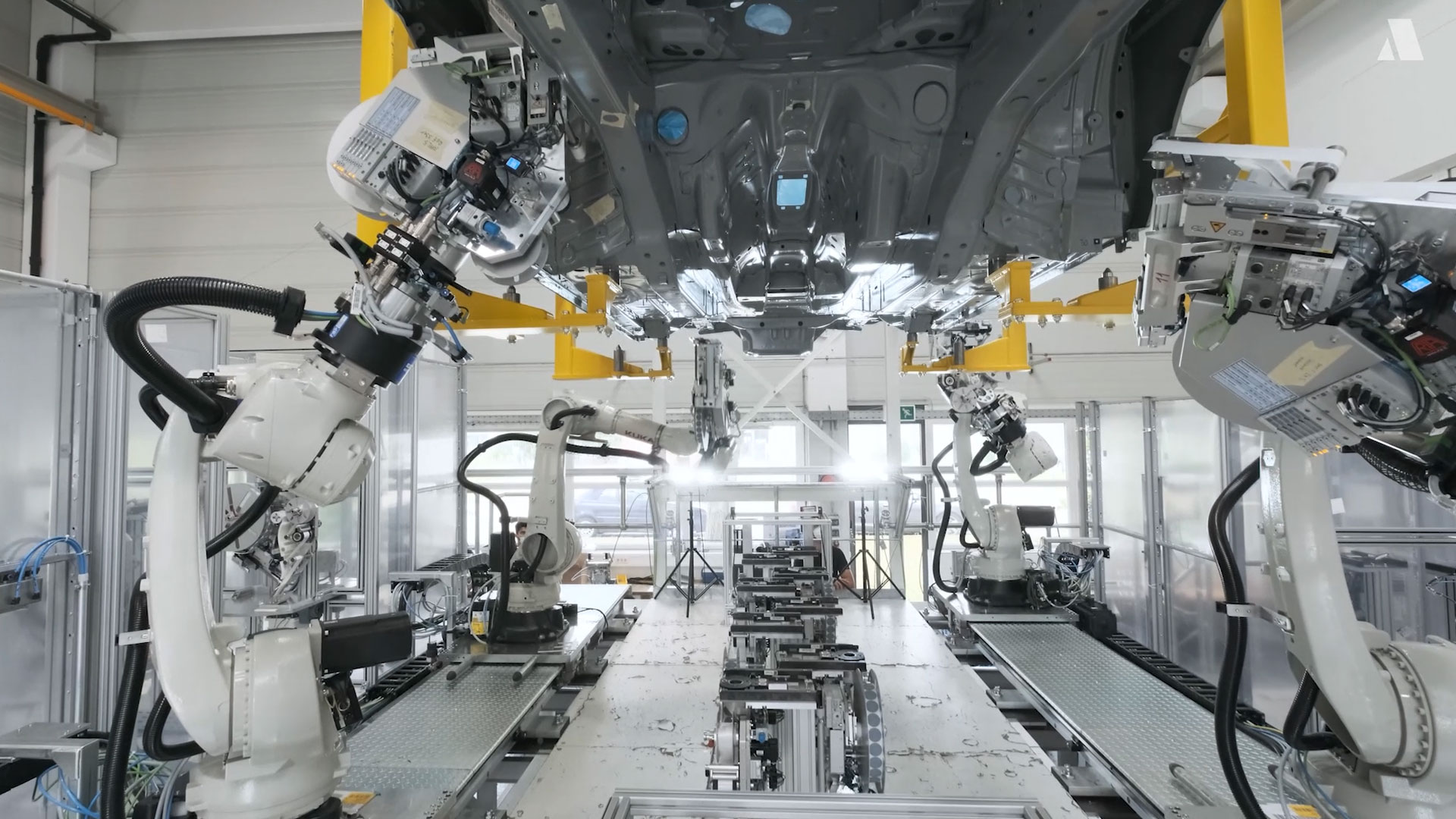

System solutions for automotive production

As a KNOW-HOW FACTORY, the Zimmer Group combines various technology areas such as handling, machine, damping and linear technology under one roof and develops customized solutions for automation tasks worldwide in the age of digital transformation. We draw on a wealth of experience in the mobility market and create system solutions for individual challenges as well as industry standards.