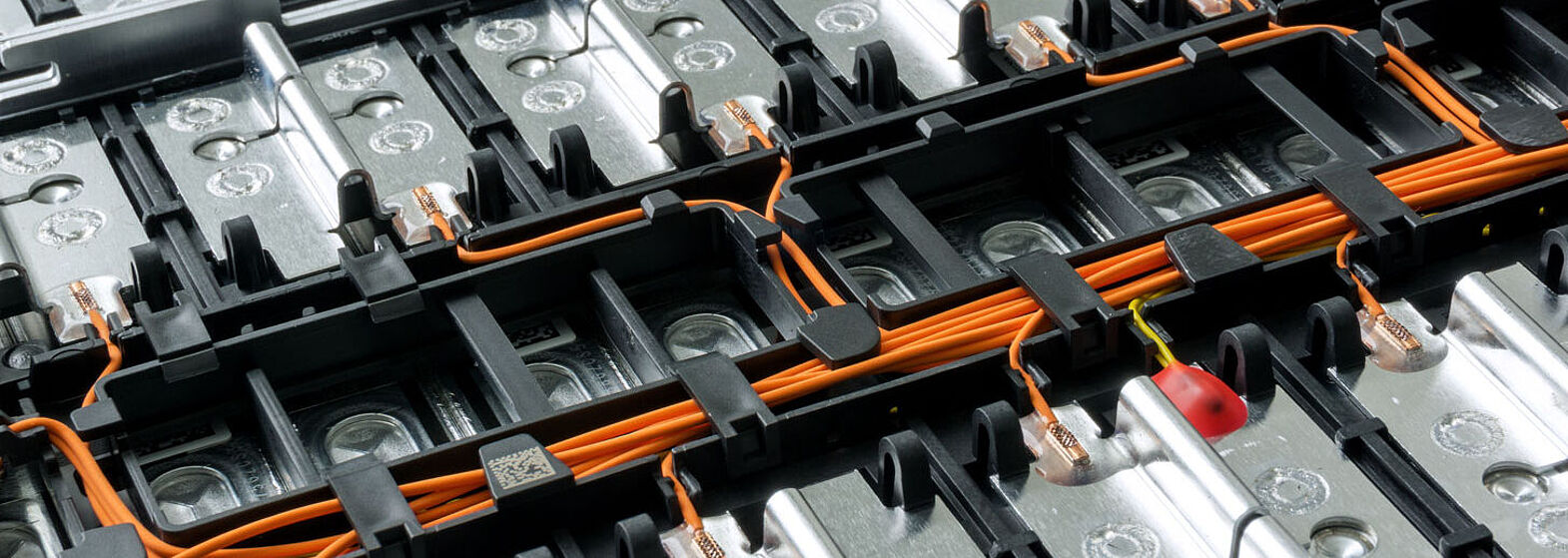

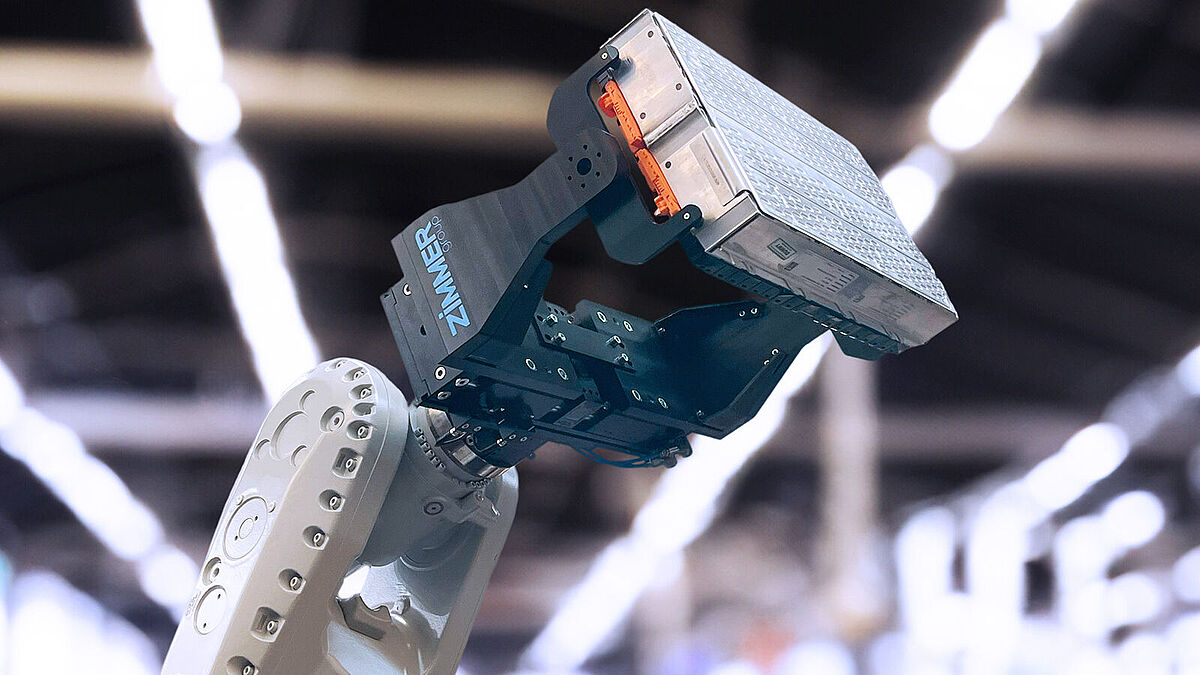

Automation technology for the battery production of electric cars

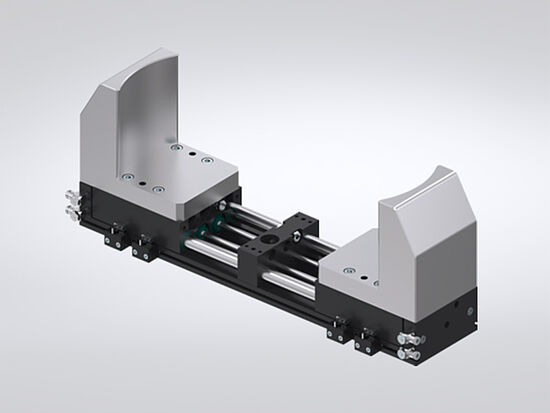

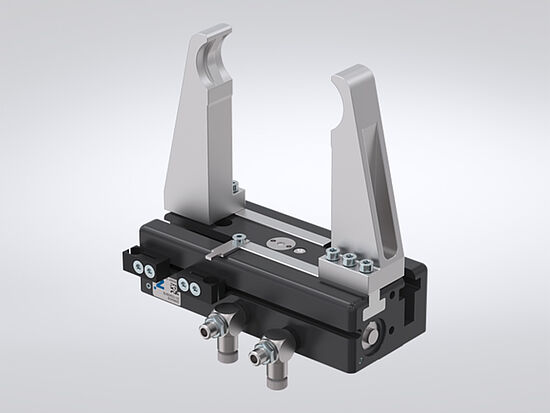

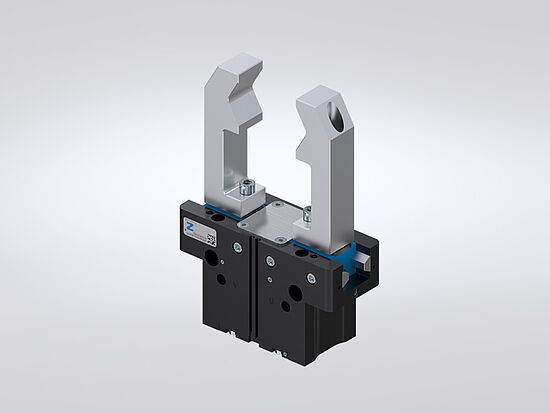

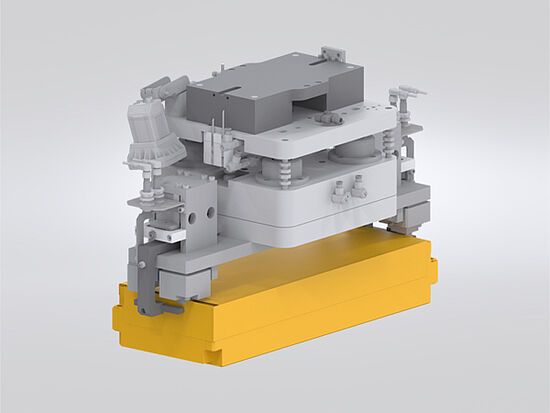

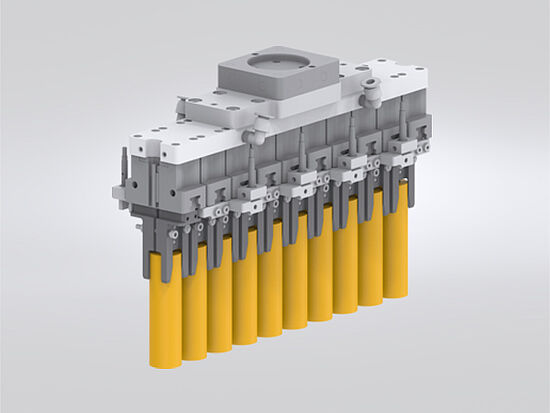

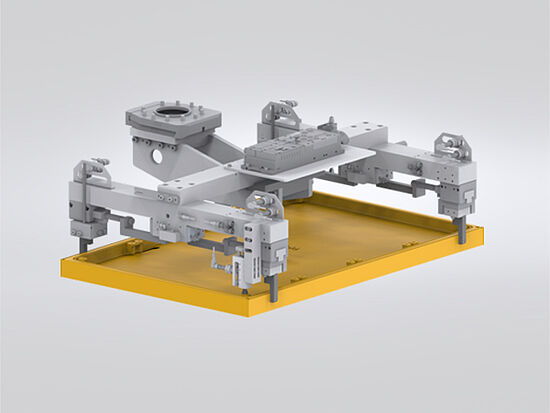

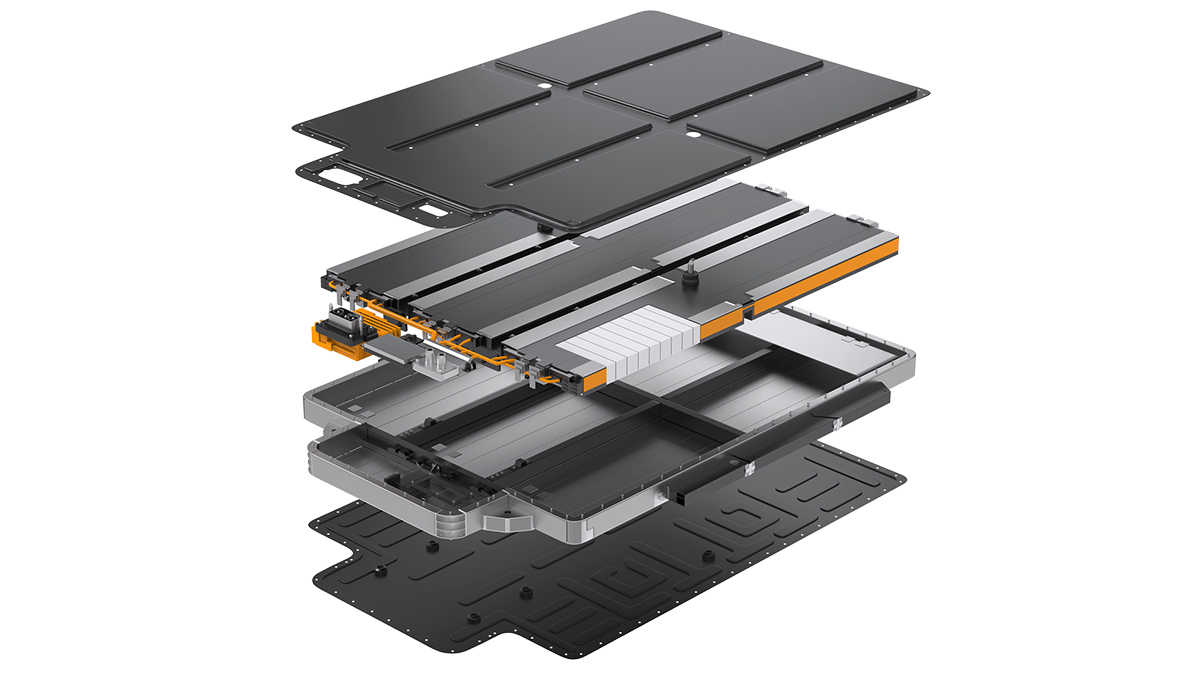

Battery production for electric vehicles places new and demanding requirements on production technology. Efficient and economic production of battery cells and packs is crucial to sustainably serving the growing market for electric cars. A high degree of automation plays a central role here. Similar to the production of combustion engines, modern and automated production is also essential in battery production. The Zimmer Group is an experienced development and system partner to numerous leading automotive manufacturers and plant constructors in the field of battery production, module assembly and electric motor production.

Do you need support in optimizing your battery production for electric vehicles? We would be happy to advise you!

In focus: The automotive industry in transition

The automotive industry has been experiencing a boom in e-mobility and a veritable paradigm shift for years. Away from the combustion engine, towards the electric drive. This development presents car manufacturers and suppliers with new challenges, and efficient battery production is just one of them. Intelligent and flexible automation solutions from the Zimmer Group are the key to sustainable mobility.