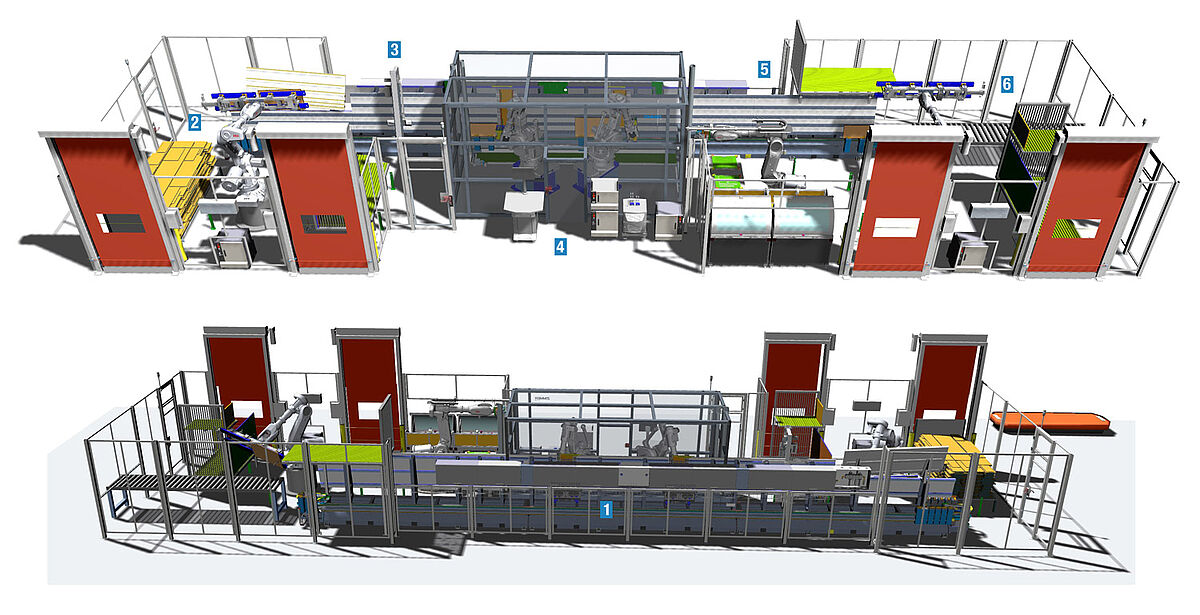

Body processing of furniture/batch size 1

Product advantages:

- Highly flexible batch size 1 system for machining furniture parts

- Machining of coated chipboards and MDF boards with dimensions from 240 mm x 120 mm up to 2,800 mm x 1,300 mm

- Output requirement of more than 600 parts per shift

- Highly flexible shuttle circulation as workpiece transport and clamping system

- Precision-compensated industrial robots for drilling machining and metal fitting

- Direct integration into the customer’s machining control system for flexible processing of the production batch

- Automatic loading and unloading with direct connection of customer-side AGV

1 Basic machine with Modular Transport System

2 Loading module

3 Measuring module

4 Processing module

5 Fitting module

6 Unloading module

Modular Transport System

Product advantages:

- Flexible transport system consisting of machine bed with linear guides and racks, rotational transfer units, intelligent movement units (shuttles), control system and user interface

- High positioning accuracy combined with high load capacity and load-bearing capacity in the direction of movement

- Scalable system in terms of circulation length and number of shuttles

- Independently programmable shuttles in terms of position, speed and acceleration

- Dynamic configuration of assemblies with flexible control of all shuttles as master or slave

1 Linear guides for absorbing weight and machining forces

2 Optimized rack and pinion drive for the highest demands on linear drive systems

3 Transmission of electrical energy and information (CAN bus) via sliding contacts

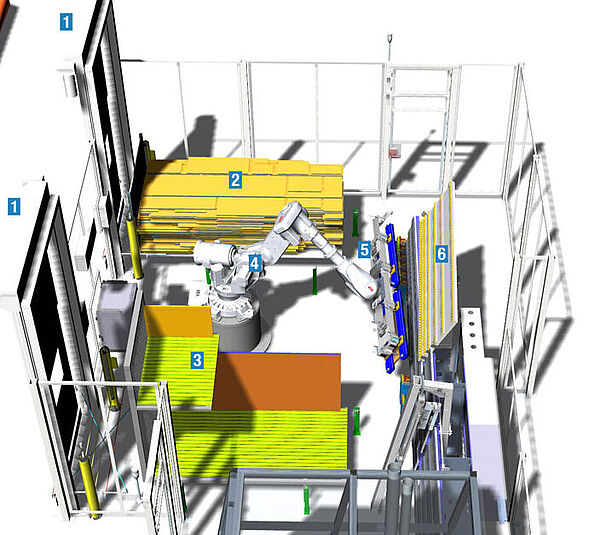

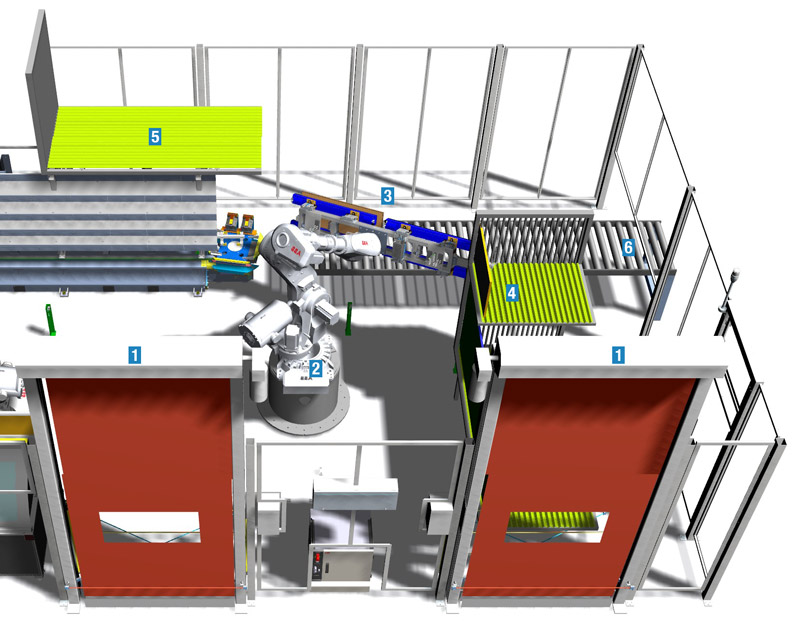

Loading module

Product advantages:

- Loading of two independent storage locations parallel to production via AGV with muting function

- 6-arm robot with individually controllable quadruple suction traverse

- Lane-by-lane loading from the new parts stack and individual loading from the tray trolley

- Label-free reading of the stack data directly via the customer’s production control system

- Alignment and separation via alignment station with plausibility check

- Provision and positioning of the shuttles depending on the part size

1 High-speed doors with muting function for automatic loading with AGVs

2 Workpiece provision as a stack

3 Workpiece provision in a rack trolley for rear-side processing

4 Loading robot

5 Suction traverse for lane-by-lane loading

6 Alignment station

Measurement module

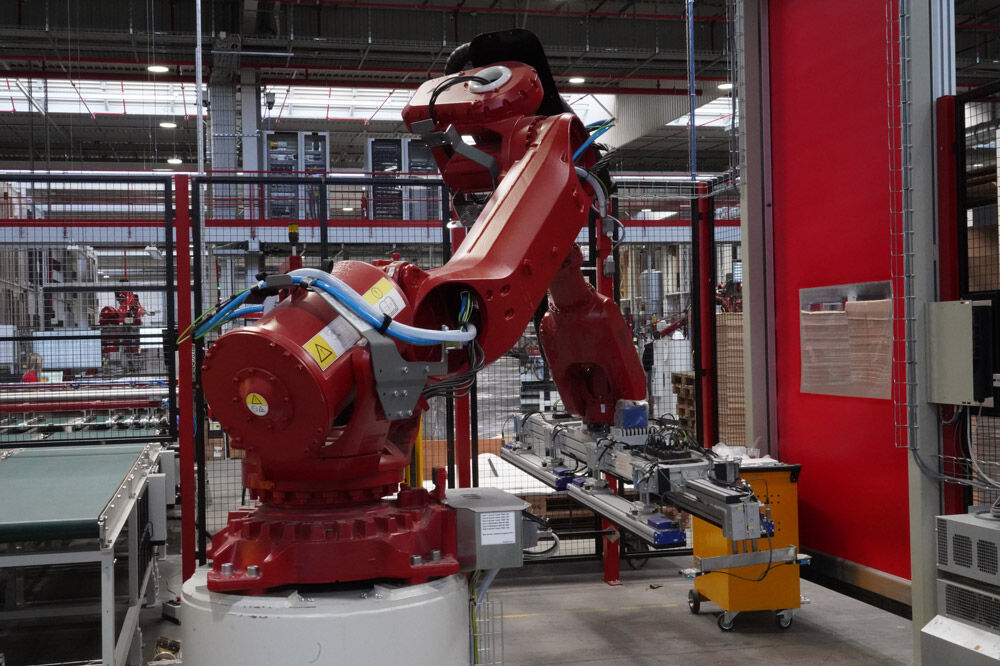

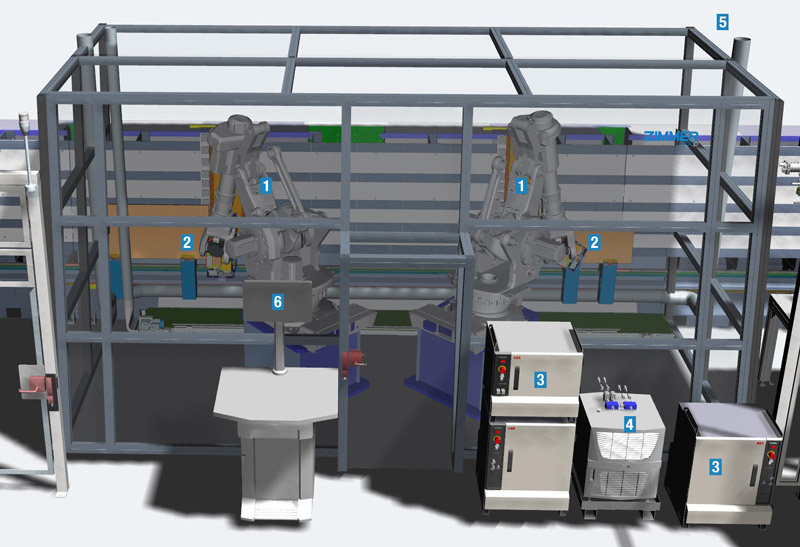

Machining module

Product advantages:

- Machining by two precision-compensated ABB machining robots and multifunctional machining heads with individually adjustable machining units

- Execution of all necessary machining functions: Grooving, milling, Clamex milling, horizontal and vertical drilling, row drilling

- Dynamic distribution of machining by upstream drilling optimizer to the two machining robots to optimize performance

1 Processing robot ABB

2 Processing head

3 Robot control

4 Spindle cooling

5 Protective cabin with suction system

6 Operating terminal

Metal fitting module

Product advantages:

- Program-controlled setting of different fitting types by a robot with multiple metal fitting head

- Manual feeding of fittings on stackable trays in the transfer station

- Provision of fittings by the robot by positioning the trays in an alignment station

1 Processing robot

2 Fitting setting head

3 Loading station for fittings

4 Alignment and supply station

Unloading module

Product advantages:

- Fully automated unloading by 6-arm robot with independently activated 4x suction traverse

- Dynamic prioritization of workpiece placement on conveyor line, tray trolley or buffer store

- Main time-parallel pick-up of tray trolleys via AGV with muting function

1 High-speed doors with muting function for automatic workpiece transport with AGV

2 Unloading robot

3 Suction traverse

4 Shelf trolley for depositing parts for rear-side machining

5 Intermediate buffer

6 Roller conveyor for workpiece transport

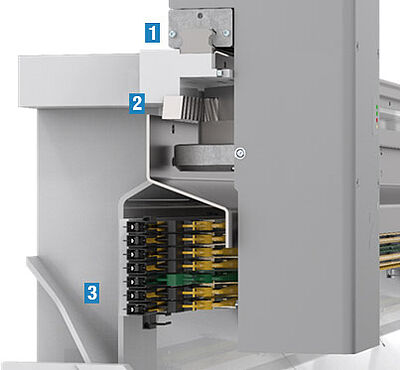

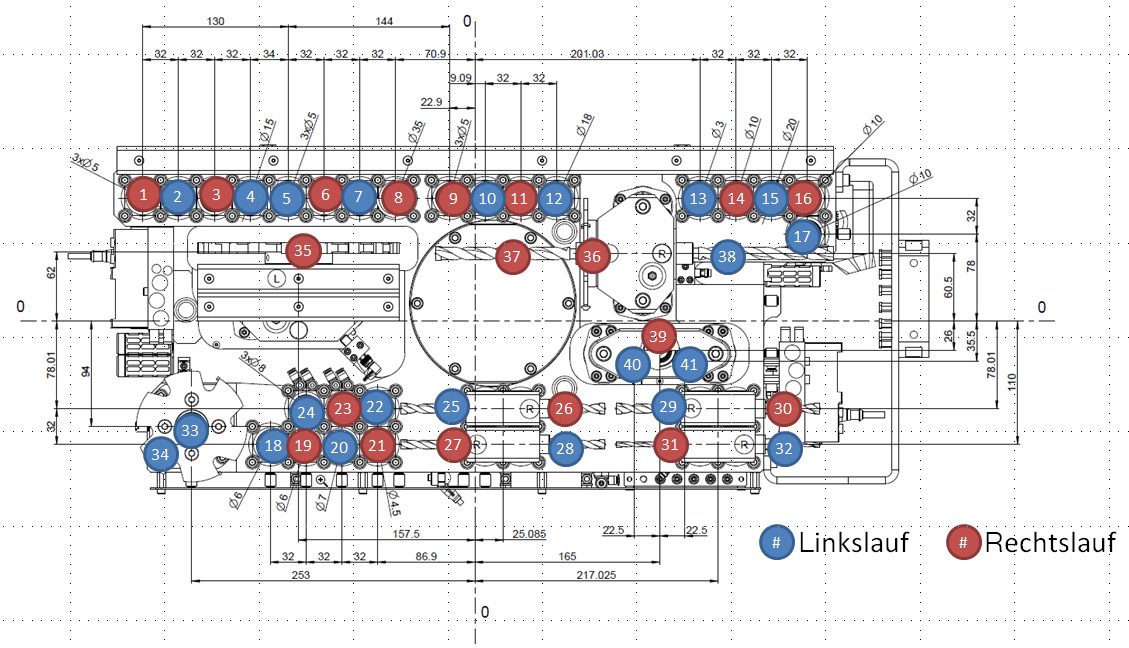

Machining head

Product advantages:

- Modular multifunctional head for implementing the various functions on the machining module

- Project-specific design of the multifunctional head for minimum space requirements and tool change effort

- Drilling unit for single and series drilling operations

1–24 Vertical drill spindles with quick-action chuck

25–31 Horizontal drill spindles with Weldon chuck

33 End mill

34 Clamex vertical

35 Grooving saw

36 Clamex horizontal

37–38 Foot drill

39–41 Hinge drilling unit