ABB robotics

Bring production environments with robots from ABB to the next level. For both industrial and collaborative robotics. In the context of automation, the requirements and challenges caused by the use of robots are becoming more and more varied, especially due to the wide range of tasks. Above all, collaborative robots from ABB, also called cobots, are capable of working hand in hand with people. In doing so, they balance the demand for maximum safety and reliability as well as the need for flexibility and productivity.

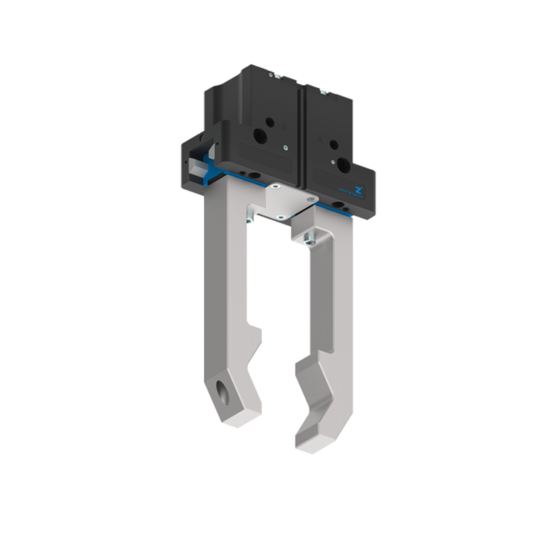

With the help of the large selection of Zimmer Group end effectors, the challenges and requirements for a wide range of application areas are covered and, together with the ecosystem of ABB robots, pave the way for automation with industrial-level performance and innovative safety and reliability. In particular, the MATCH ecosystem ensures maximum compatibility and flexibility in handling thanks to the universal, robot-specific standardized communication interface. This not only brings together speed with maximum precision, it also bridges the gaps between collaborative and industrial robots – even in applications that require speed and lifting capacity on an industrial level.

Application areas

THE ECOSYSTEM

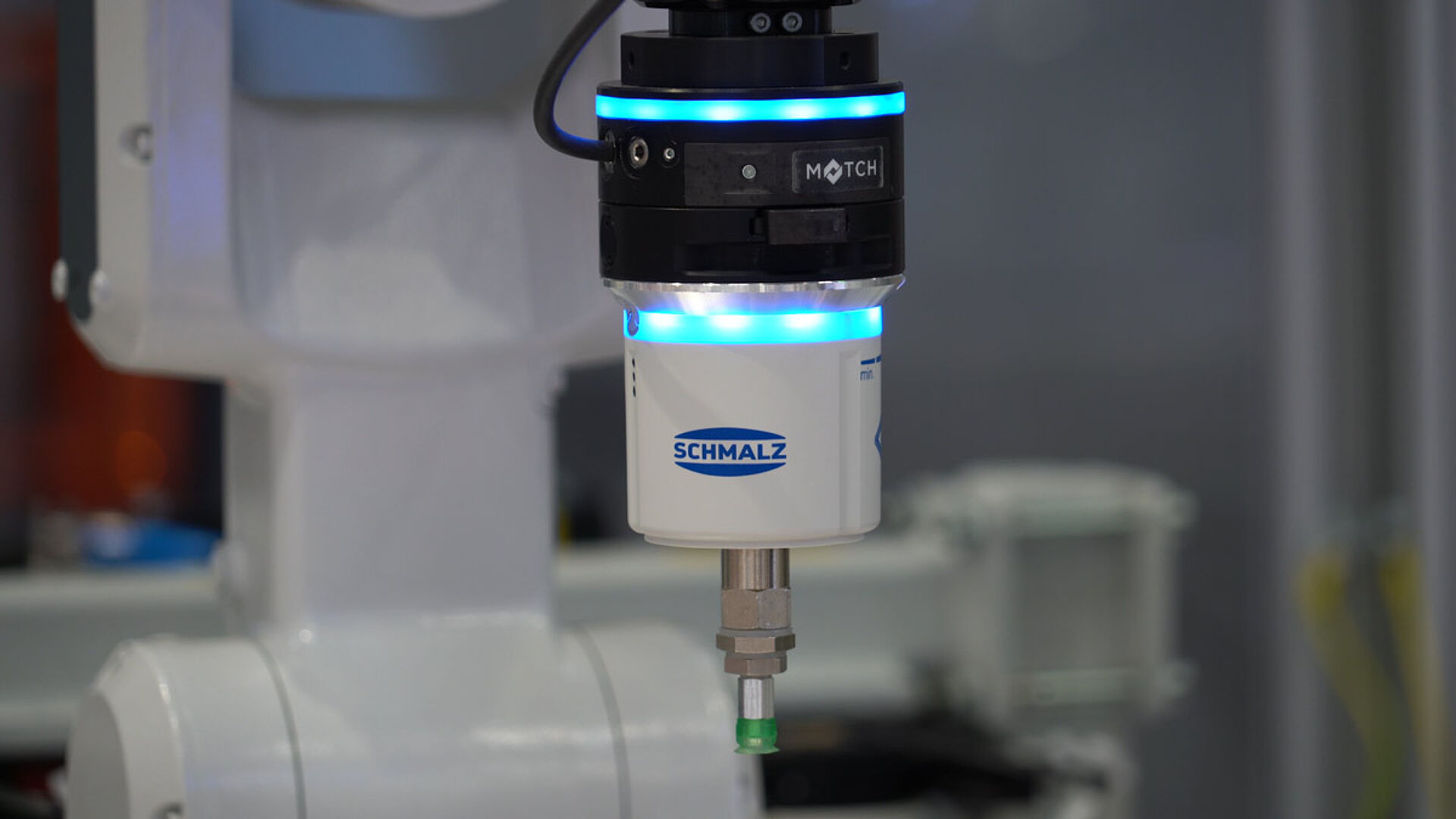

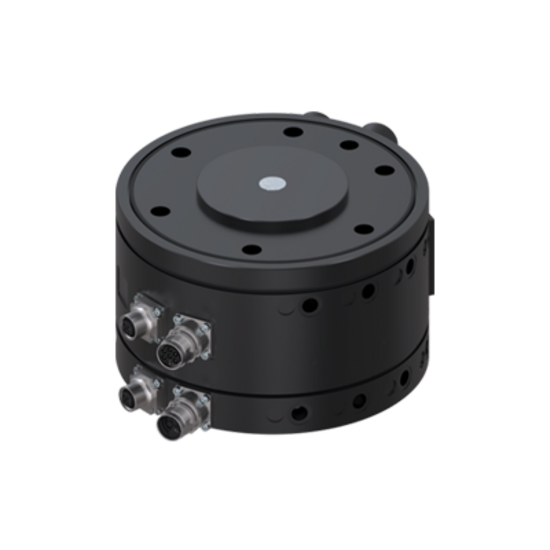

With easy installation and a standardized MATCH interface, the ecosystem of ABB robots can be combined with the product portfolio of the Zimmer Group quickly and without complications. Furthermore, vacuum grippers from J. Schmalz GmbH can also be integrated with MATCH. This not only simplifies optimal adjustment to constantly changing production requirements and processes, but also enables unproblematic use for future applications and projects.

The large selection of end effectors is especially paving the way for automation by opening up a wide variety of application areas. The ready-made package from Zimmer Group – consisting of hardware and software components – combines ABB robots and gripping and vacuum technologies into a uniform system. Simplified machine communication is ensured with the standardized, mechanical combination of ABB robots and MATCH robot modules. With the help of the MATCH ecosystem, all essential communication parameters are received by the robots, ensuring fast integration without complications. The combination of ecosystems from ABB and Zimmer Group opens up new spheres in terms of performance, versatility, affordability and operability.

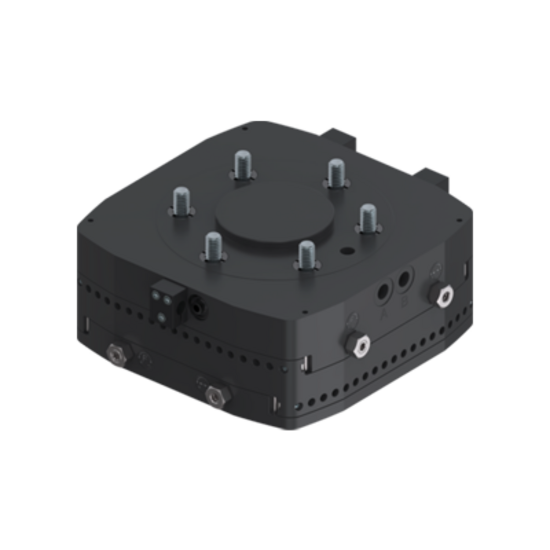

SMART COMMUNICATION MODULE FOR ABB ROBOTS

Ready-to-connect for speedy commissioning

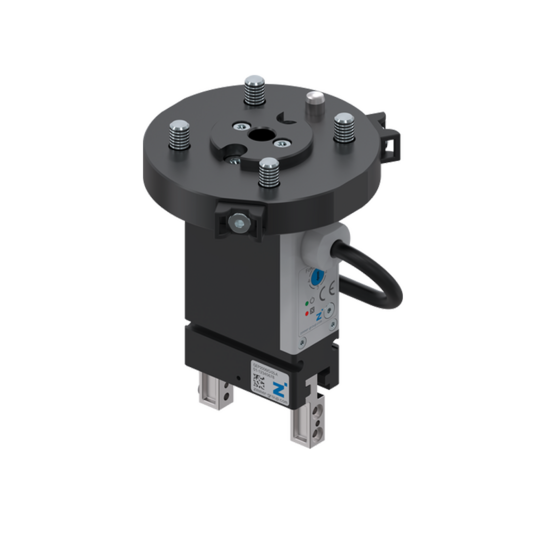

Thanks to the ready-to-connect communication modules from Zimmer Group, activating and integrating intelligent IO-Link and Digital IO grippers with cobots and industrial robots from ABB is as easy as can be. Here, the Smart Communication Module (SCM) from Zimmer Group translates the IO-Link communication system into digital inputs and outputs (Digital I/O) and vice versa, thus ensuring secure and fast communication. To set up this information exchange optimally and as simply as possible, prepared cable sets for ABB robots are available.

Simple activation of grippers

No matter which grippers from Zimmer Group you have, all IO-Link gripper components can be used with ABB robots thanks to the ready-to-connect MATCH robot module. As a gateway for the end effector, the SCM – a ready-to-connect communication module – communicates with the robot control system. This ensures complete and simultaneously easy activation of the end effector, without losses and with maximum safety and reliability. The uniform interface ensures maximum compatibility with ABB robots. The voltage is supplied directly by the robot, and information is transferred from the robot flange to the ABB robot control system reliably and without faults.

Intuitive software

The Comfort app makes it possible to control and operate the gripper conveniently and directly via the robot control panel – easy to set up and featuring all the necessary commands for smooth automatic operation. Pre-stored function blocks make commissioning and programming easier and ensure a productive, reliable robot application. The interaction of robots from ABB and end effectors from Zimmer Group ensures highly precise, optimal work in the world of collaborative robotics and industrial robots.

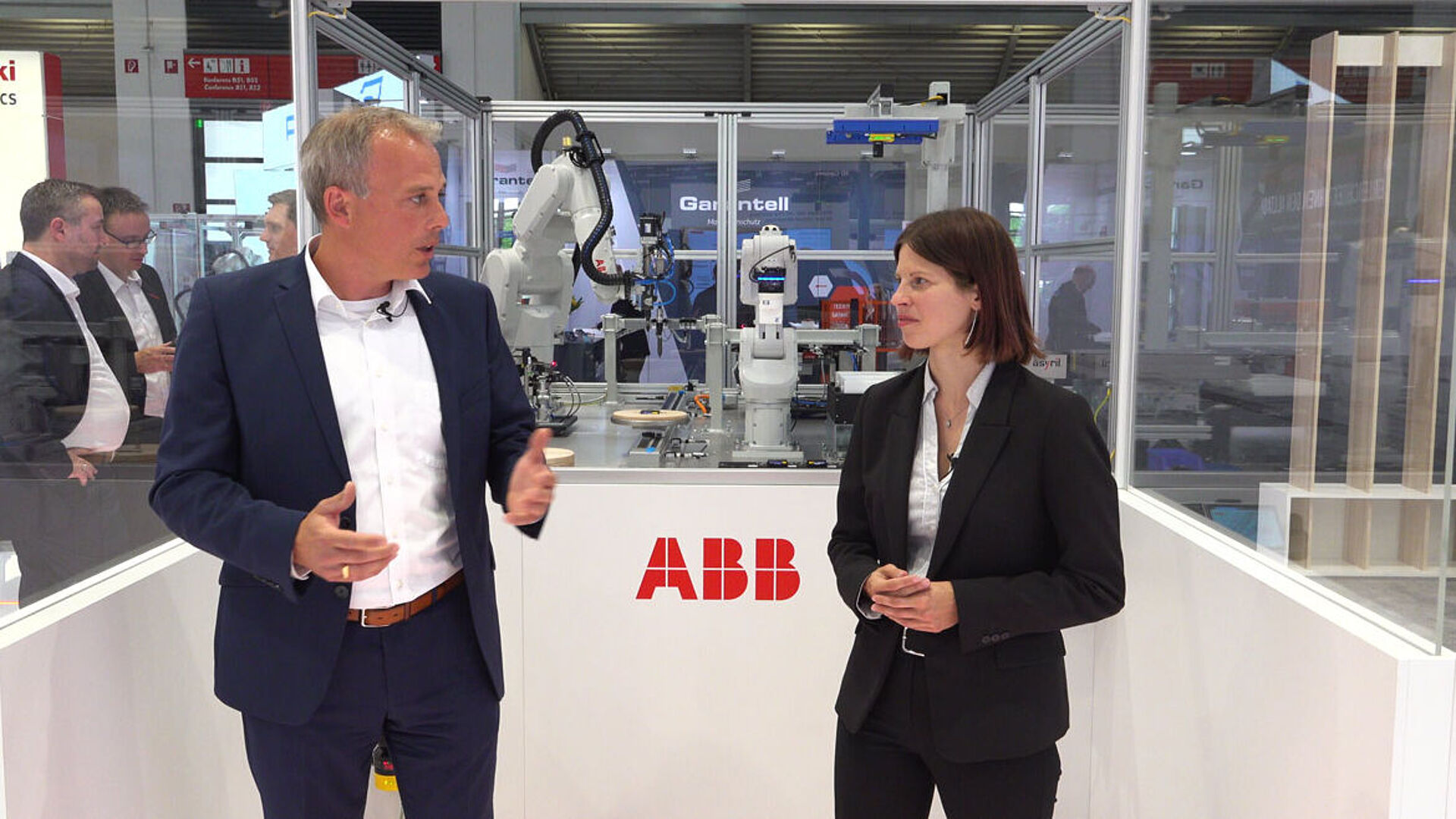

What do you offer your customers as a well-known manufacturer in the area of robotics?

Katja Butterweck: "ABB offers a broad portfolio in the area of automation, including industrial robots, cobots, mobile robotics and also industry-leading software. What does this look like at Zimmer Group?"

Kai Kohler (Zimmer Group): "Zimmer Group is the solution provider in the field of end-of-arm tooling, components, as well as entire system solutions, culminating in the robot flange – both in the field of traditional industrial robotics and in the new area of cobots. Here, we can develop solutions together. And we are using the new MATCH system here in the plant. Katja, why did ABB decide on this system?"

How does our product portfolio come into play? Can you explain the connection between robots and our handling solutions?

Katja Butterweck: "We have three families for cobots: the Switfi, GoFa, and YuMi. And particularly for cobots, we see that ease-of-use is extremely important. If I want to implement an application, it is usually not enough for me to say that I just need the robot. Instead, the tool also has to be a part of it. So we said, "OK, we will look for a partner." With Zimmer Group, we found a partner who offers a package that is a perfect fit. The great thing is that this work not only for the cobots but also for industrial robots. Here is where we specifically said that the great thing about the MATCH system is that two major partners have come together – Schmalz and the Zimmer Group – to provide their knowledge. We know that we have a high-quality system with automatic and manual changers, which works wonderfully for this application shown here."

Kai Kohler (Zimmer Group): “As an interface, MATCH is compatible between Schmalz and the Zimmer Group. There's mechanical gripping and a vacuum. It's suitable for cobots and small IRBs, and even includes software integration in the teach pendant. In other words, it's as easy and flexible as possible for the customer. This means that if the robot is completing application A today, but application B comes along tomorrow with a different workpiece, you're prepared with MATCH and can simply use another end effector."

Where is the future of robotics heading? Trends?

Katja Butterweck: "And that is also the major challenge that we see with customers. There are a number of solutions. But which is the right one? On the one hand, we have packages that include everything, with hardware and software. Yet what sets Zimmer Group and ABB apart is that we guide the customer, from the first idea of "I want automation here" up to a running application."

Kai Kohler (Zimmer Group): "Exactly, that is very important to us: helping the customer from the beginning and supporting them in finding the best solution."

ROBOTICS PRODUCT FINDER

Use this intelligent search to find the right accessories and grippers for your system! Well-informed selection suggestions give you an overview of a variety of products. It also clearly shows the most important data for the suggested products. Additional filters and specific application data help you limit your search results and conveniently get you to your goal.

Gripper Product Finder

This online tool helps you find the perfect gripper for your application with just a few application parameters. Sort your search results by stroke, gripping force or drive force and select from our extensive portfolio of handling technology.