System reference

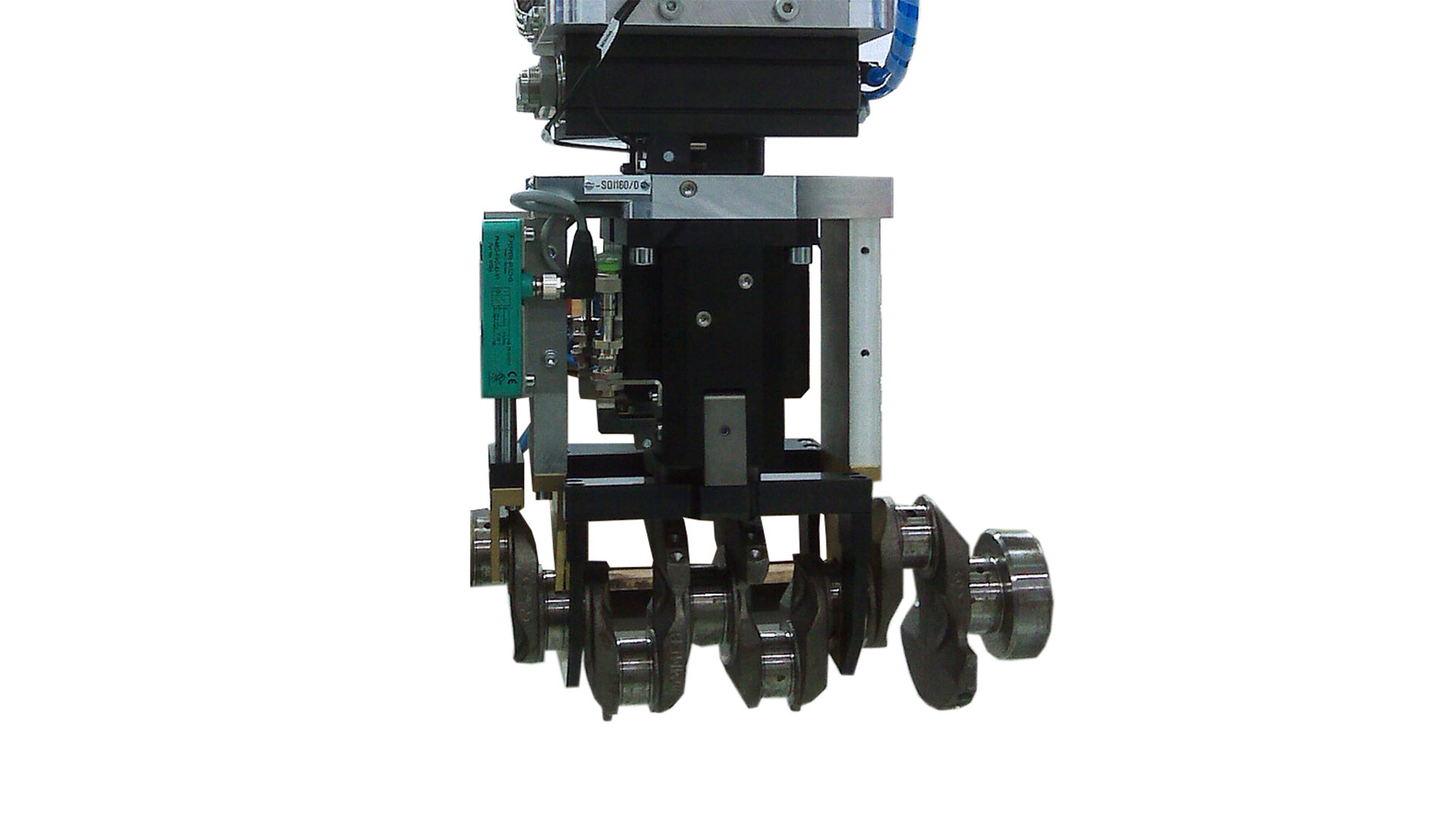

Gripper for crankshafts

System solutions | Mobility | Automobile | Drive train for combustion engines

Flat Swivel Units

Series SF-C

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

1. Swivel and rotary modules

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

Challenge

On a crankshaft production line, a gripper needed to provide feedback about the gripped part when loading and unloading a tooling machine for the purpose of checking for the correct part. The high level of part variance was another challenge.

Solution

A standard swivel unit and a standard angular gripper were used for gripping the parts. The type check took place using an analog stroke measurement system that transmitted the exact bearing diameter to the control system.

Highlights and technical data

IP40

IP40 Pneumatic

Pneumatic External gripping

External gripping Gripping force safety device for spring

Gripping force safety device for spring

Technical Data

| Drive type | PNEU |

| Max. gripping force | 18000 [N] |

| Gripping concept | FORM |

| Gripping safety device | FED |

| Max. stroke | 40 ["] |

| IP class | IP40 |

| System weight | 24 [kg] |

| Max. workpiece weight | 15 [kg] |

| Max. workpiece temperature | 80 [°C] |

Built-in standard components