System reference

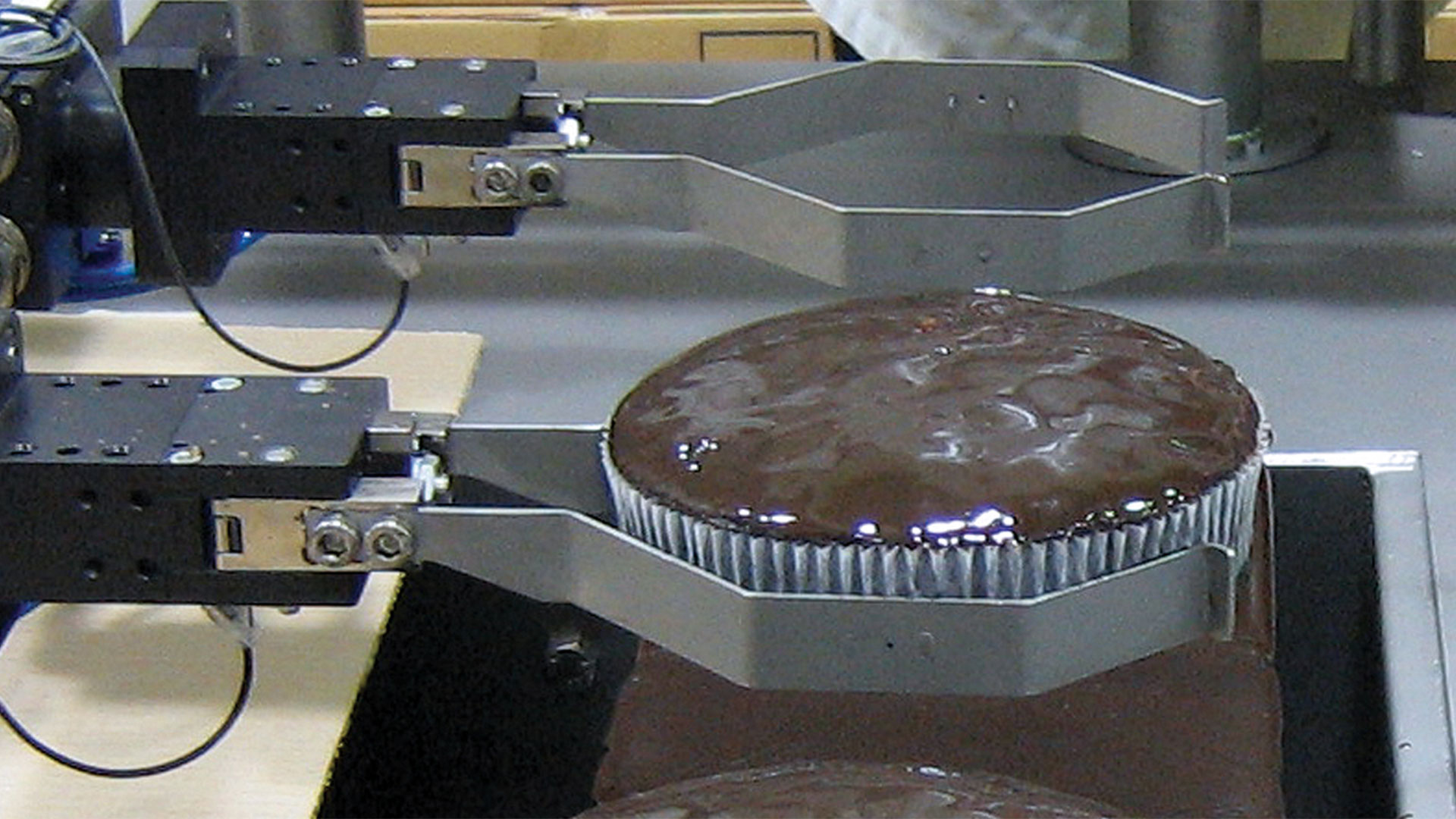

Gripper for chocolate muffins

Swivel and rotary modules | System solutions | Consumer goods | Food and beverages

Flat Swivel Units

Series SF-C

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

2-jaw radial gripper

Series GK

1. Swivel and rotary modules

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

Challenge

In the production of chocolate muffins, the muffins needed to be dipped in a chocolate bath. The special handling challenge here was creating a food-grade gripper system design.

Solution

The basis of the design is a GK series standard angular gripper. This gripper was fabricated with jaws made of food-grade VA material as well as being modified with food-grade lubrication. An SF-C series standard swivel unit is used for rotation.

Highlights and technical data

Stainless steel

Stainless steel IP40

IP40 Pneumatic

Pneumatic External gripping

External gripping Gripping force safety device for spring

Gripping force safety device for spring

Technical Data

| Drive type | PNEU |

| Max. gripping force | 610 [N] |

| Gripping concept | KRAFT |

| Gripping safety device | FED |

| Max. stroke | 180 ["] |

| IP class | IP40 |

| System weight | 2 [kg] |

| Max. workpiece weight | 0.1 [kg] |

| Max. workpiece temperature | 80 [°C] |

Built-in standard components