EOATs and gripper systems for logistics

The digital evolution is changing markets worldwide and posing new challenges for logistics. Different industries require specific solutions: from efficient intralogistics and flexible distribution centers to the vision of the “smart warehouse”. As a leading manufacturer of end-of-arm tools (EOAT), the Zimmer Group develops gripper solutions that are tailored to current and future requirements in logistics and intralogistics.

Zimmer Group: Customized robotic grippers for modern logistics processes

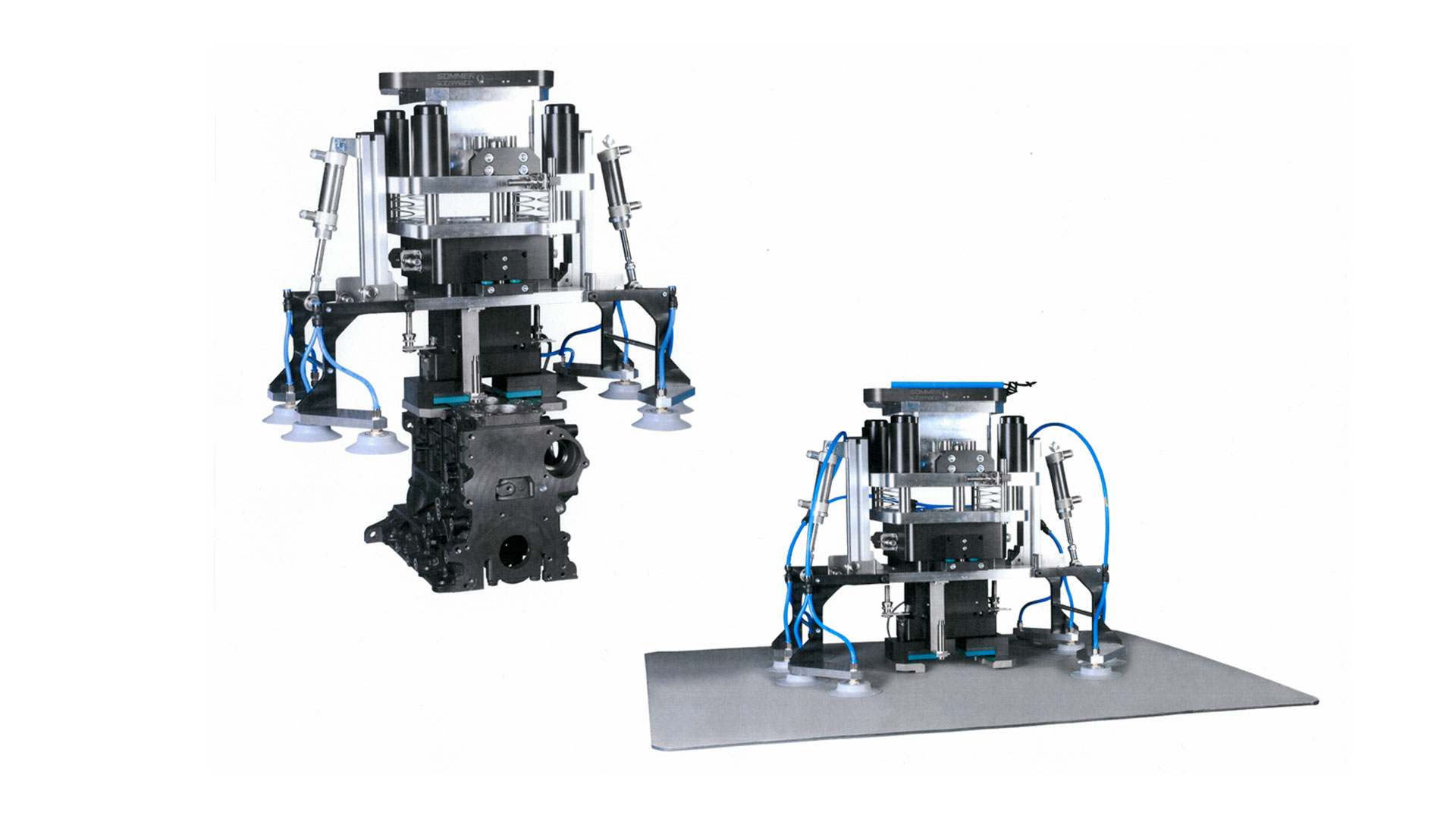

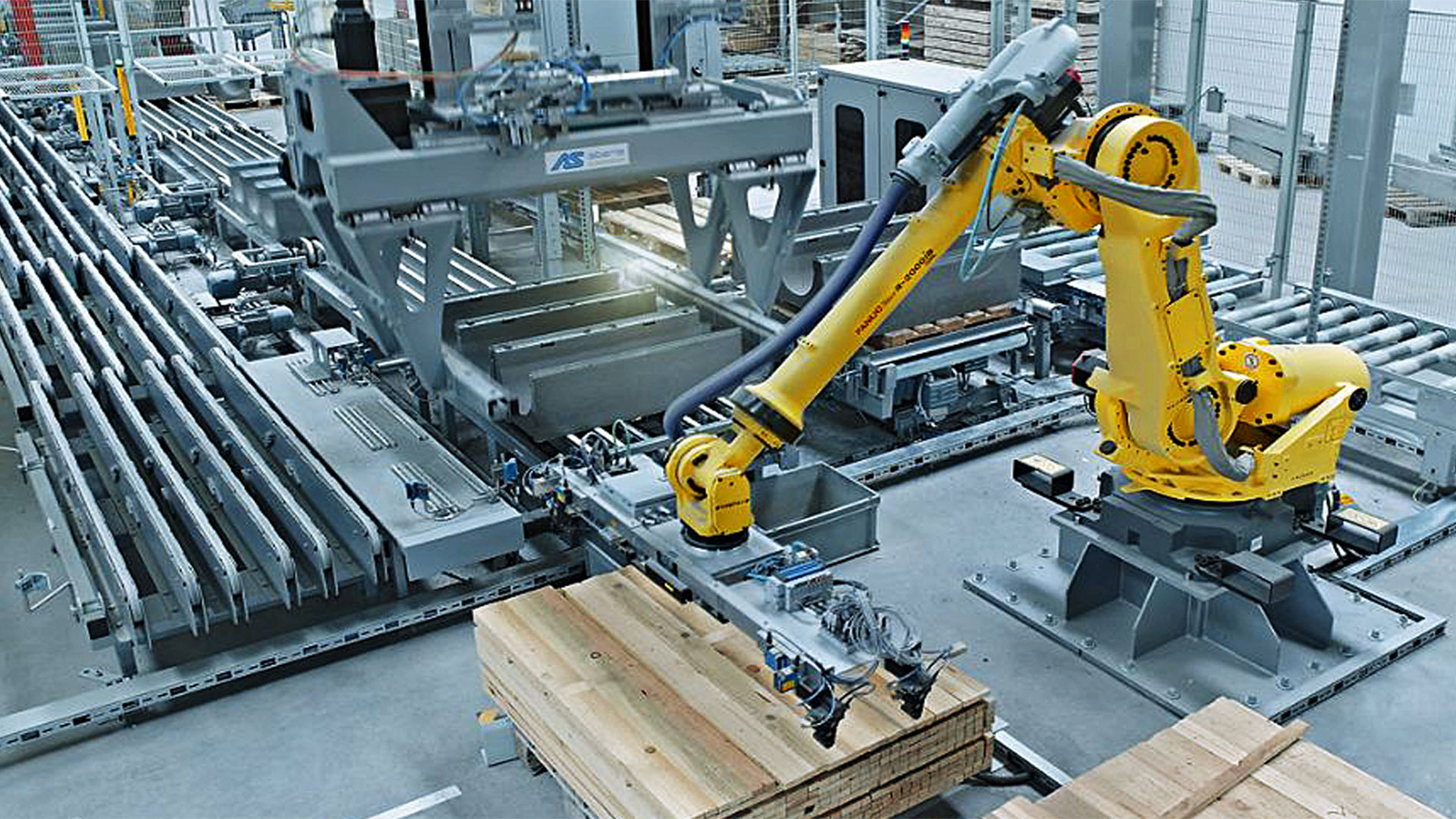

The Zimmer Group’s grippers offer high flexibility and precision and are designed to meet the requirements of demanding production environments. As the link between robots and materials, they play a central role in intralogistics. Component recognition plays a crucial role here: Equipped with intelligent vision systems, grippers can precisely identify components, recognize their position and optimally grip them for automated further transport. This technology is particularly valuable for adaptability in intralogistics, as it ensures a high level of process reliability and efficiency when product requirements change.

Do you have any questions or would you like individual advice? Write to us!

Products

Efficient picking with our automated item picking system

Our innovative system combines gripper and vacuum suction technology in a single solution. It enables fast and precise handling of cartons and ensures efficient loading and unloading of load carriers. With an impressive pick rate of up to 600 picks per hour, you can increase your productivity and optimize your logistics processes.

KLT and carton handling with EOATs

This video shows how special end-of-arm tooling (EOAT) solutions are used for handling small load carriers and cartons. Whether gripping, moving or stacking – robot-assisted automation with EOAT has become an integral part of (intra-)logistics processes and is becoming increasingly important. The automated processes ensure optimized logistics and reduce manual effort. Efficient small load carrier handling is particularly important in the automotive industry, electronics production and other sectors in which many small parts are processed and stored.