YASKAWA robotics

In the context of automation, the requirements and challenges caused by the use of robots are becoming more and more varied, especially due to the wide range of tasks – no matter whether they are repetitive or include different process flows. In the field of industrial robots, Yaskawa covers all applications in logistics, pharmaceuticals and the food industry. In addition, collaborative robotics from Yaskawa combine key aspects such as performance, versatility, affordability and operability with industrial strength. This not only enables automation processes and highly precise work in close proximity to people, it also ensures maximum safety and reliability.

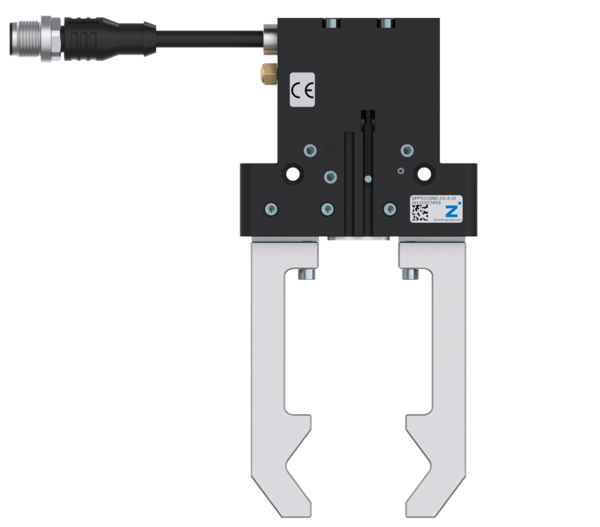

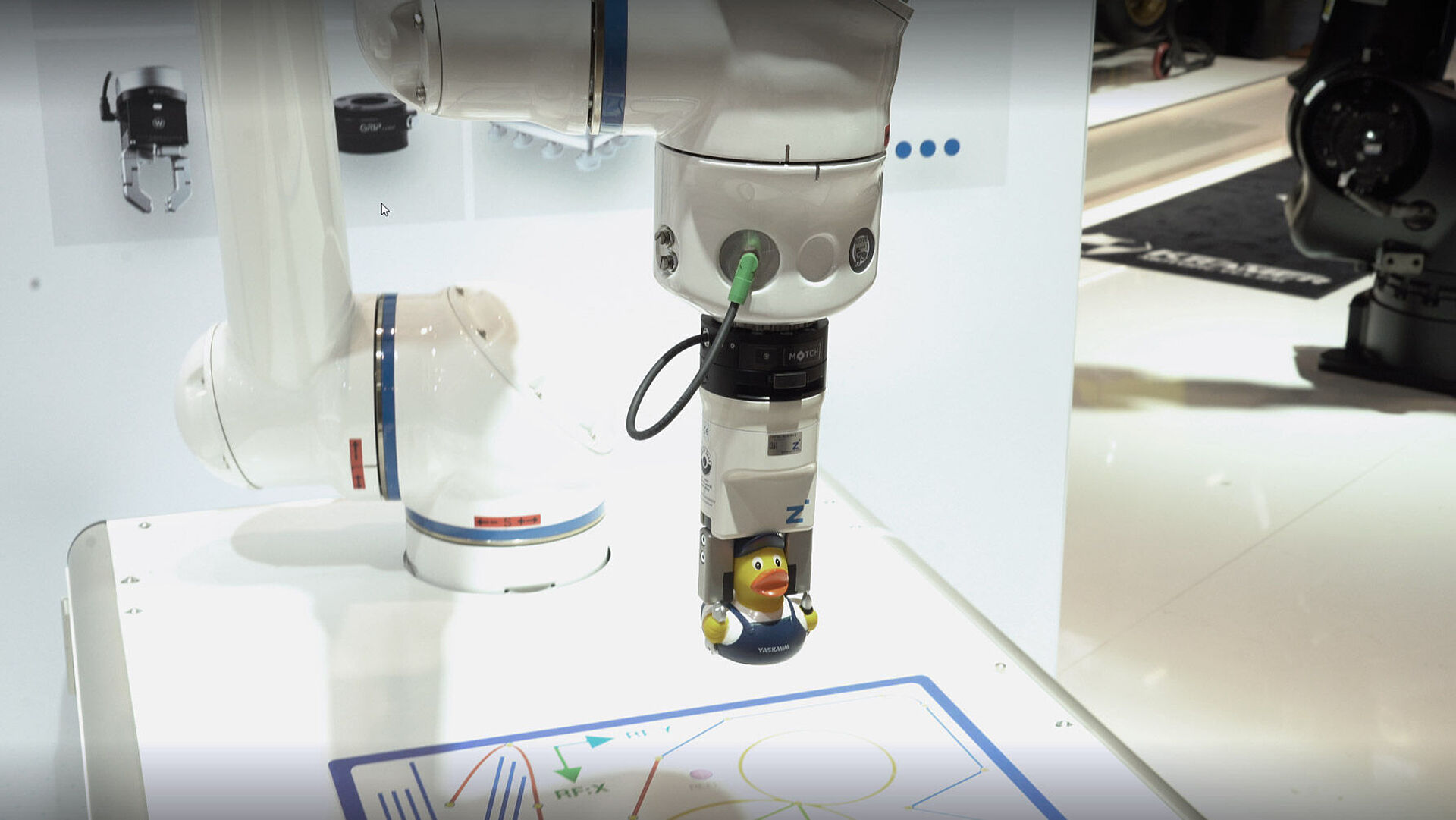

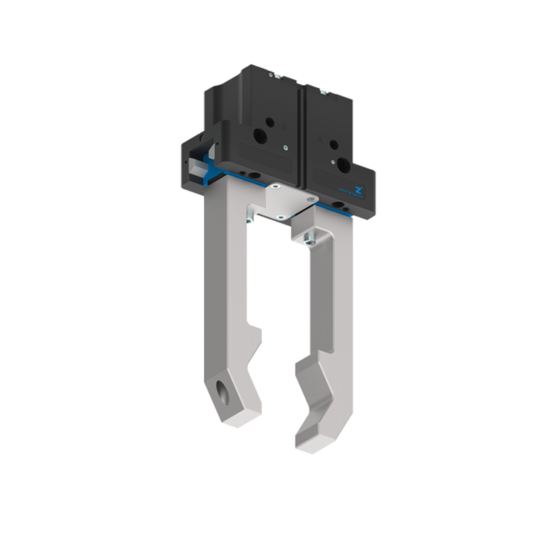

Thanks to the extensive selection of end effectors from the Zimmer Group, you can fully meet the challenges and requirements of a wide range of application areas. On the cutting edge, the MATCH ecosystem ensures maximum compatibility and flexibility in handling thanks to the universal, robot-specific standardized communication interface.

YOUR BENEFITS

- Increased overall productivity

- Higher quality due to high precision

- Adapted and optimized production processes

- Long-term reductions in manufacturing costs

- Implementation of complex production processes

Application areas

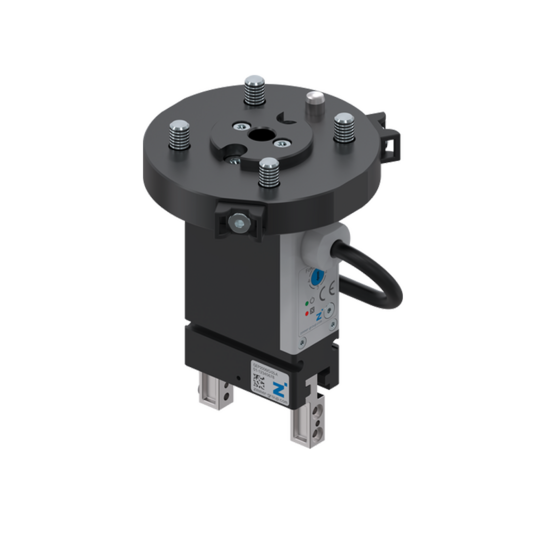

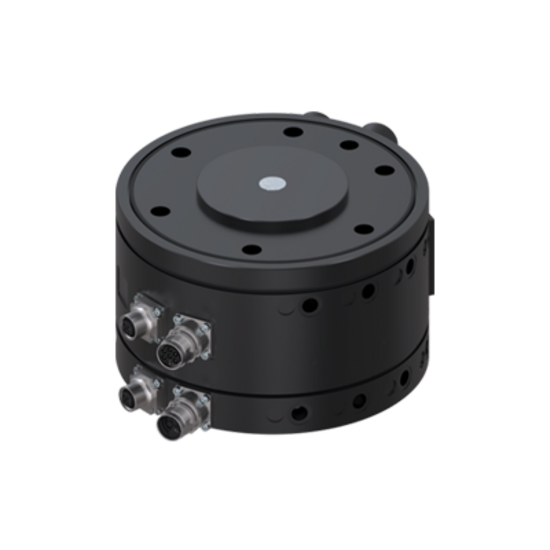

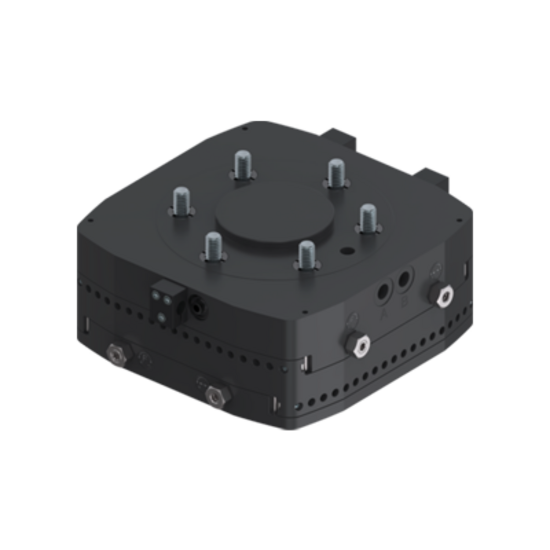

SMART COMMUNICATION MODULE FOR YASKAWA ROBOTS

Straightforward commissioning thanks to ready-to-connect modules

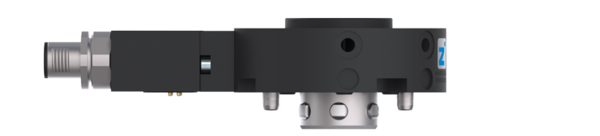

Thanks to the ready-to-connect communication modules from Zimmer Group, activating and integrating intelligent IO-Link and Digital IO grippers with cobots and industrial robots from YASKAWA is as easy as can be. Here, the Smart Communication Module (SCM) from Zimmer Group translates the IO-Link communication system into digital inputs and outputs (Digital I/O) and vice versa, thus ensuring data exchange to the robot control system for the most information possible. For optimal setup of this information transfer, the connection can be established using the appropriate connection cable for Yaskawa components.

Your choice of IO-Link gripper

No matter which grippers from Zimmer Group you have, all IO-Link gripper components can be used with the right adapter plate between the specific Yaskawa robot flange and ISO pitch circle. As a gateway for the end effector, the integrated SCM communication module communicates with the robot control system, thus ensuring complete and simultaneously easy activation of the end effector – reliably and without faults. The uniform interface enables maximum compatibility with Yaskawa robots. Power is supplied directly by the robot. This way, information is transferred from the robot flange to the YCR1000 robot control system.

Activation and configuration without programming skills

The combination of the Comfort app and YCR1000 control panel makes activation and commissioning of the gripper convenient and direct via the teach pendant, thus combining the advantages of an easy setup, including essential commands for efficient programming and smooth automatic operation. The stored software function blocks make commissioning and programming convenient, so it is easy to ensure that the robot application is productive and reliable. The interaction of Yaskawa robots with end effectors from Zimmer Group thus delivers collaborative robotic systems and industrial robots that are highly precise and perform at their best.

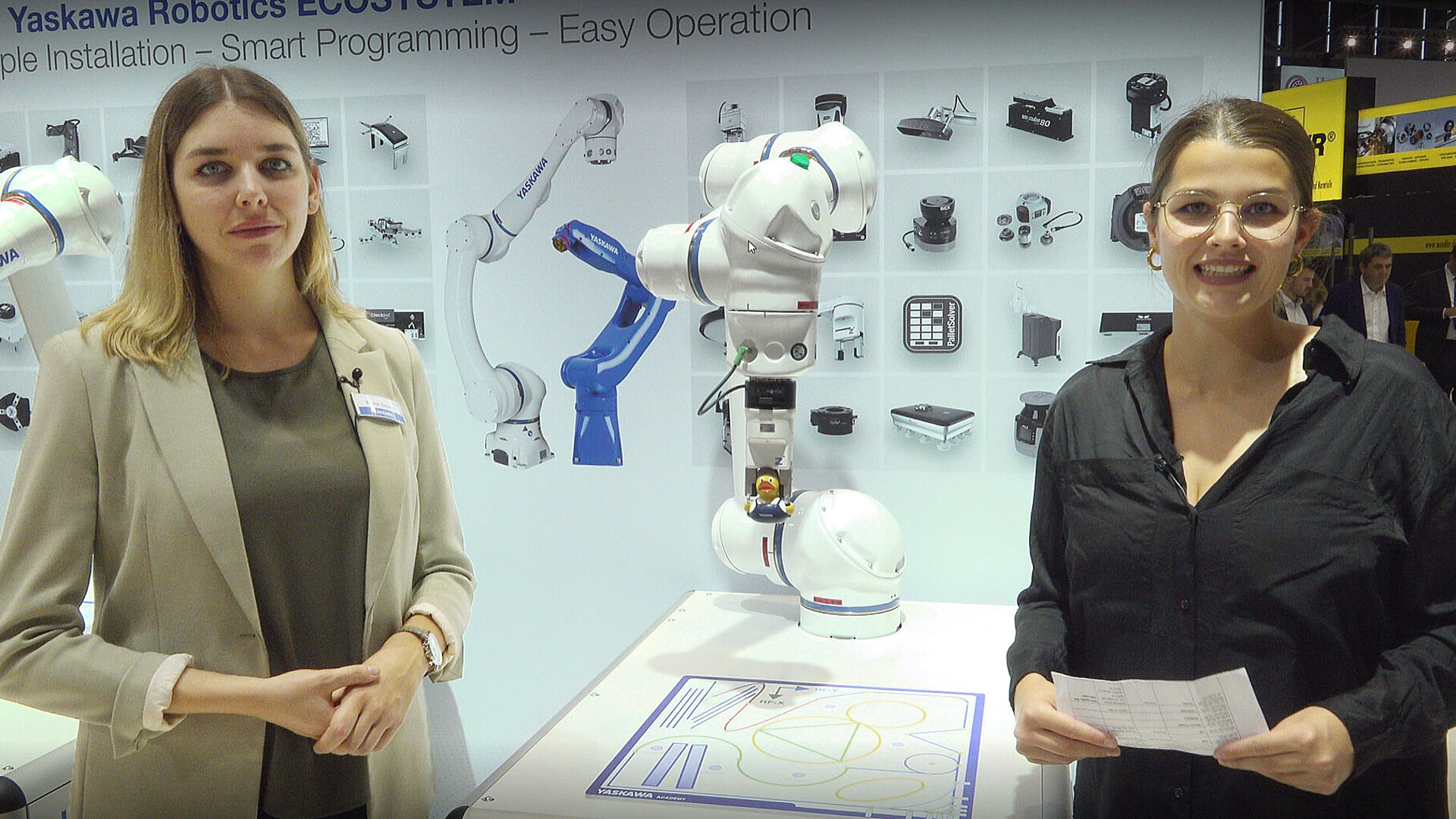

What does Yaskawa offer its customers as a robot manufacturer?

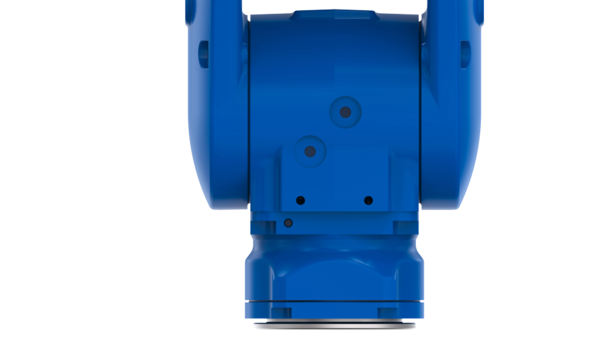

Tasmin Schales: "We have various options, especially within the ecosystem. For example, we offer cobots that people can work with directly, as well as industrial robots. The Yaskawa robots are blue the blue ones."

Kai Kohler (Zimmer Group): "And why exactly are you using the MATCH ecosystem here?"

Tasmin Schales: "We saw here that the MATCH ecosystem is a perfect match for our robots. This is because we have the option to connect grippers using the same interface and the same software interface for cobots as well as for industrial robots. So, no matter how we want to program it, there are always the same interfaces on our end."

Kai Kohler (Zimmer Group): "A quick look into the future of robotics: Where does Yaskawa think the future lies?"

Tasmin Schales: "So, when we focus specifically on the ecosystem, we see that we want to grow naturally and offer our customers the opportunity to find specific solutions to their applications within our range. This also goes beyond grippers. This means that with a MATCH ecosystem from Zimmer we can equip entire cells with other peripheral equipment, both from us in-house as well as third-party products."

Kai Kohler (Zimmer Group): "And where are the challenges for Yaskawa?"

Tasmin Schales: "We are seeing more and more that we have to dive deeper, and also that we have to continuously realign ourselves to meet customer-specific criteria, since we need to offer the customer more starting points for robotics, especially when it comes to cobots. This is a little different than the standard offered by industrial robots. So now we have to use different routes to take customers by the hand a bit and guide them to robotics."

Kai Kohler (Zimmer Group): "Great, thank you for this fascinating interview. We wish you much continued success!"

ROBOTICS PRODUCT FINDER

Search 2,000 robotics components to find the right solution for your application quickly and conveniently. The intelligent search uses the most important selection criteria to guide you to well-informed selection proposals. In addition to the suggested products, you also get a quick and clear overview of the most important data. Narrow down your search results with additional filters and specific application parameters.

Gripper Product Finder

Use this online tool to get an overview of our extensive product range and find the perfect grippers for your application. Sort your search results by stroke, gripping force or drive type and calculate your specific parameters.