End-of-arm ecosystem

Any Robot. Any Gripper. Any end effector.

The new multifunctional end-of-arm platform from the two technology leaders and handling specialists Zimmer Group and Schmalz. Equipped with an extensive portfolio of functions and universal communication interfaces, MATCH is compatible with every standard lightweight robot on the market – a system ideal for cobots and conventional 6-axis robots.

YOUR BENEFITS

- A single system for lightweight robots, cobots and conventional robots

- Compatibility & flexibility – combining the primary handling technologies (vacuum and mechanical gripping)

- Long service life, even in automated continuous operation

- Innovative digital ecosystem

- Large variety of end effectors

- Manual exchange with easy-click function

- Automated change in the device

- Recommended by ABB, one of the leading manufacturers of robots

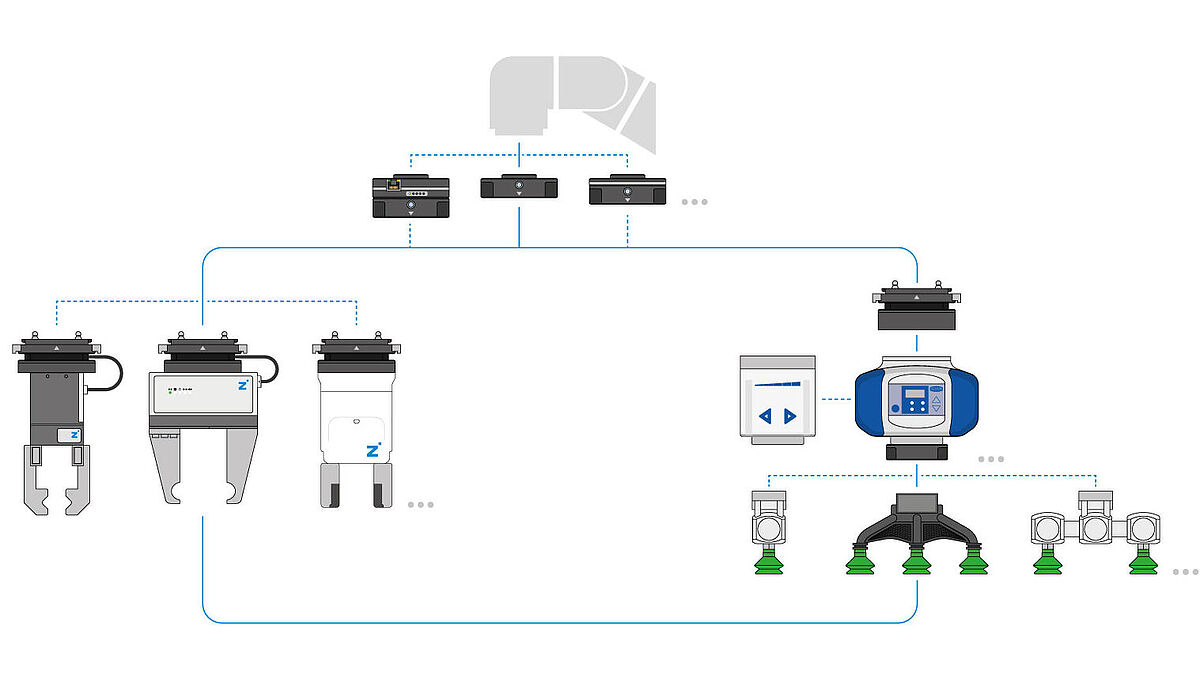

STANDARDIZATION OF THE ROBOT INTERFACE

The MATCH series offers unique standardization potential: The MATCH robot module can be mounted on the most common robot types and acts as a connector for the entire range of MATCH-compatible end effectors. The standardized robot connection flanges offer a high degree of flexibility in the choice of applications. The attached end effectors, whether grippers or suction cups, can be easily exchanged manually or automatically using a click system. Standardized and ready-to-connect solutions guarantee maximum system availability.

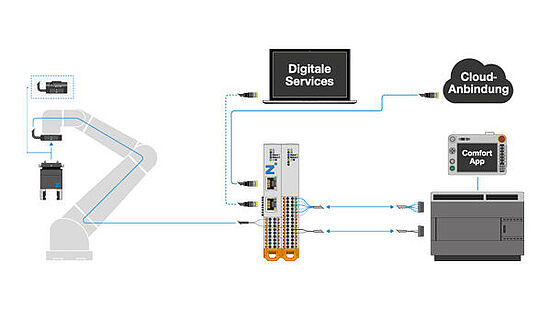

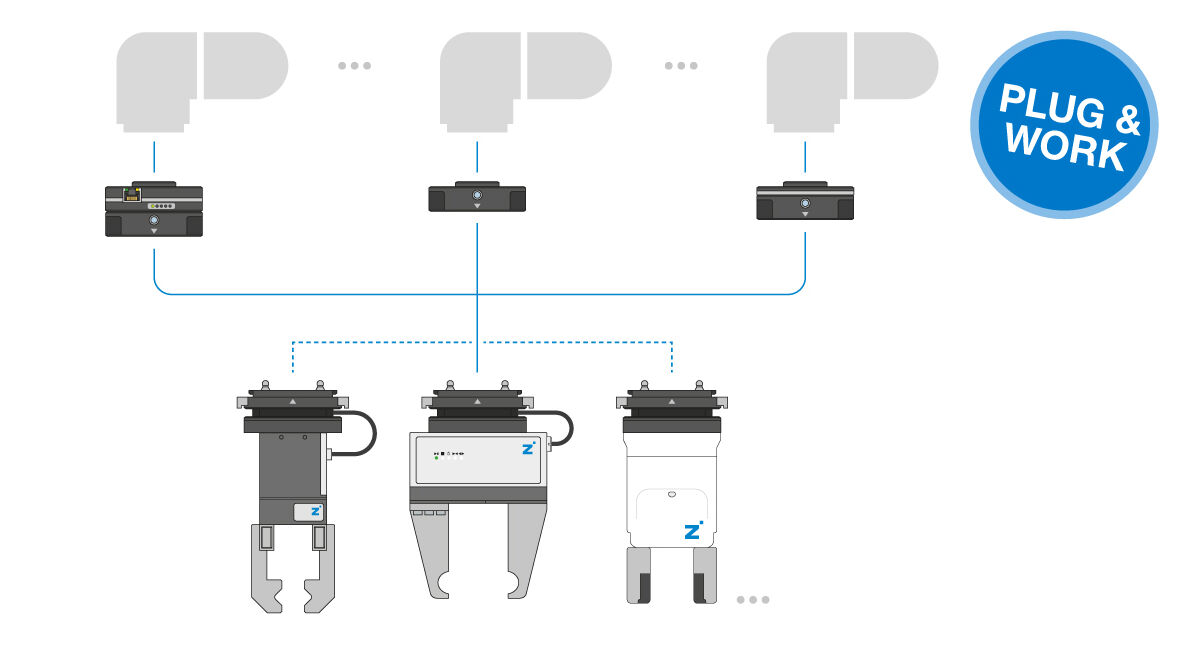

PLUG & WORK – SIMPLIFIED COMMUNICATION INTERFACE

In addition to a uniform mechanical connection between the robot arm and end effector, MATCH also simplifies machine communication. The MATCH robot modules are available in Digital I/O and IO-Link versions or come with their own Smart Communication Module. MATCH provides the necessary communication parameters to integrate robots from different manufacturers with the MATCH system via Plug&Work.

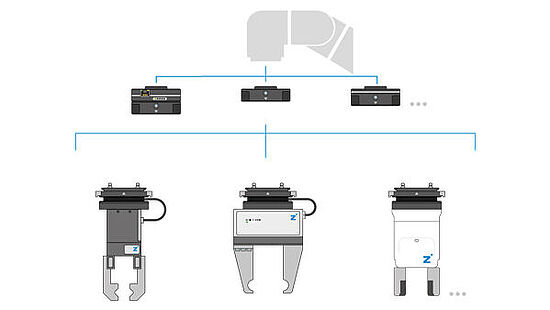

MATCH ECOSYSTEM – LARGE SELECTION OF END EFFECTORS

The MATCH portfolio includes a large selection of Zimmer Group grippers. This is not limited to use in lightweight robotics and human-robot cooperation, but is also suitable for use in industrial and heavy-duty robots. In addition to Zimmer Group grippers, end effectors with vacuum technology from Schmalz are also compatible with the MATCH ecosystem. The MATCH ecosystem consists not only of the physical components, but also includes various software solutions: An app tailored to the respective robot manufacturer enables direct control and monitoring of the functions.

COMPLEX ROBOT APPLICATIONS WITH AUTOMATED SWITCHING

The future of automated production envisages an increase in efficiency through the flexible use of a robot. This means that one and the same robot can perform several different tasks on one workpiece by automatically changing the end effector. In addition, standardization simplifies the process for operators and integrators.

The MATCH product range enables not only an automated change of the end effector but also the use of the same suction cup or gripper by different robot types and systems. The key components here are the MATCH robot modules, which are available for a wide range of robots from the most popular manufacturers.

MATCH

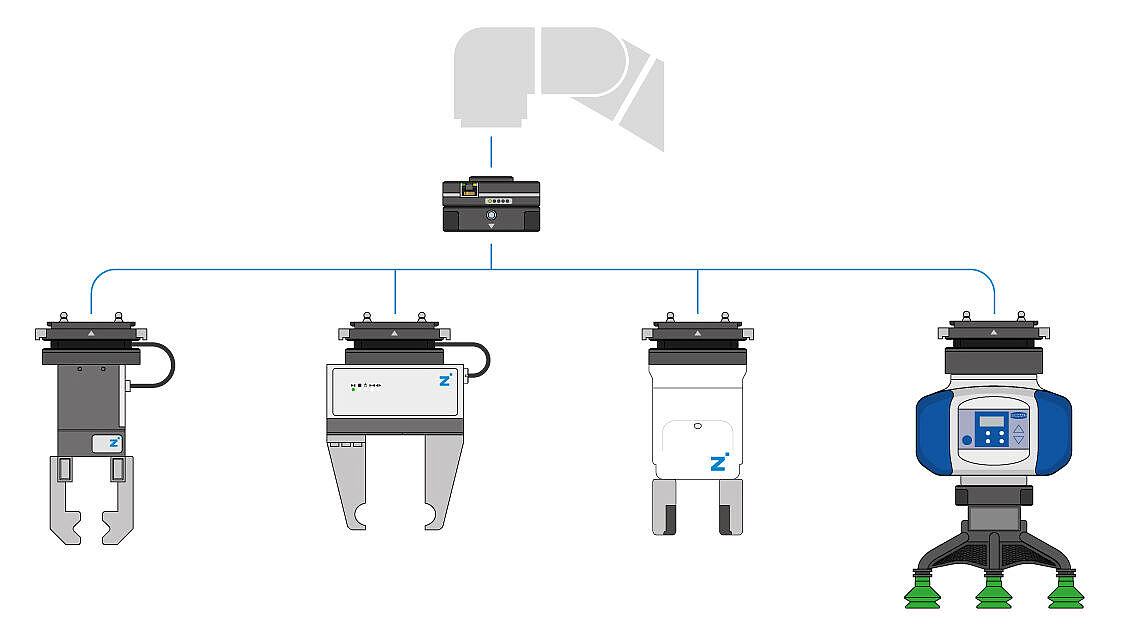

Components

0 Robot flange

1 Communication module

2 Robot module

3 MATCH gripper

4 Software

The MATCH series offers flexible and fast setup of the robot application thanks to robot-specific, standardized interfaces. The simple design also enables a high degree of flexibility, allowing a wide range of tasks to be carried out by one or more robots.

Conventional

Components

0 Robot flange

1 Communication module

2 Adaptation to robot flange

3 Multifunctional level

4 Tool changer

5 Adaptation to end effector

6 End effector

When configuring a robot cell with conventional components, the exact components required for the customer-specific application can be selected from a wide range of products.

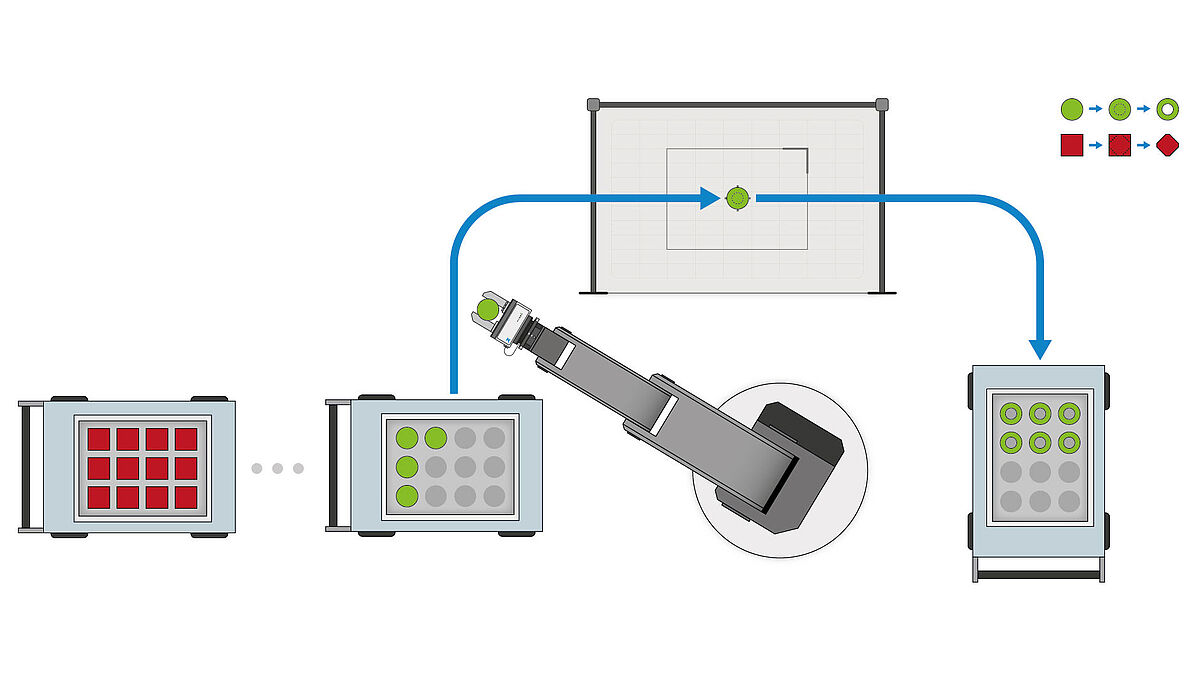

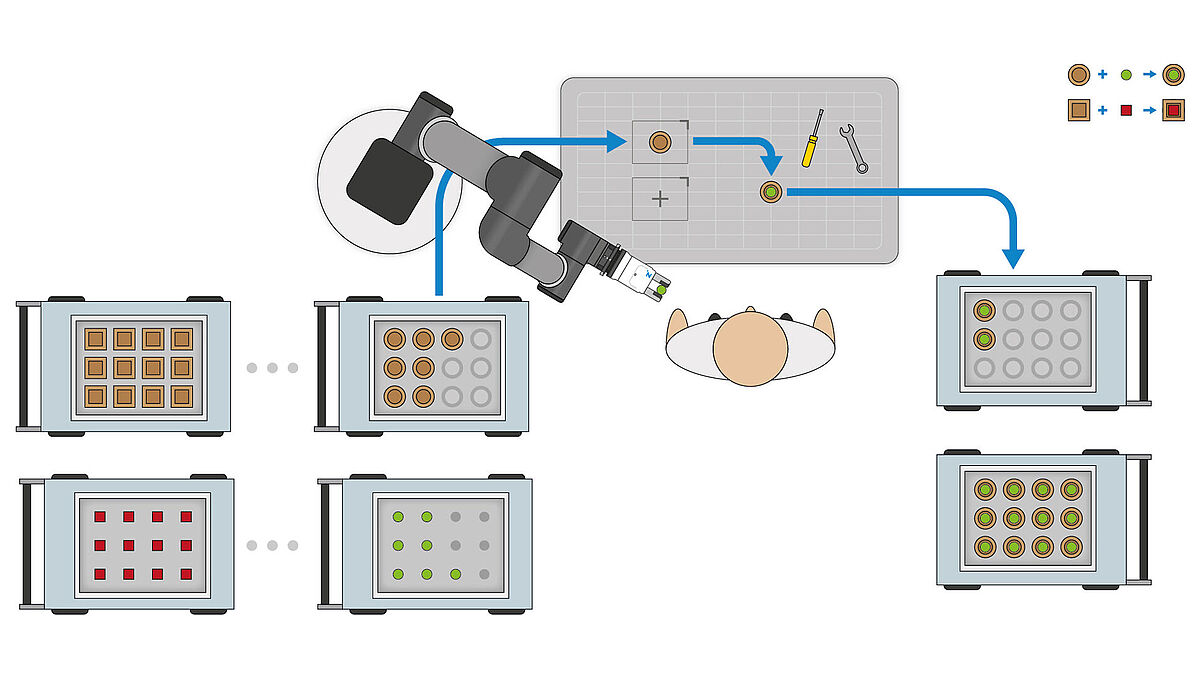

EXAMPLE OF AUTOMATED MACHINE EQUIPPING FOR LOW QUANTITIES

With a comprehensive ECOSYSTEM of grippers from normal- to large-stroke as well as suction and vacuum components that are adapted flexibly to the respective workpiece, machine loading can handle low quantities due to fast adaption times and simplified servicing.

MATCH on cobots and industrial robots from ABB

Robot manufacturers worldwide have seen the simple and flexible integration of end effectors for themselves – for example, ABB recommends the MATCH ecosystem including collaborative gripper for its robots. In this video, we show you how the robot module equips you for almost any application.

MATCH for cobots and industrial robots from ABB

FULL PROCESS CONTROL FOR EVERY APPLICATION

MATCH guarantees you full support and process control – from commissioning to ongoing operation and process monitoring. Digital services such as HMI functions for setup and operation, recording of process data/condition monitoring, evaluation and visualization and cloud connection offer added value in all phases of the product life cycle.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/4/9/csm_ZIM_BIL_PRO_MATCH-BAHNHOF-1__SALL__AQU__V1_bcc011b3af.jpg)