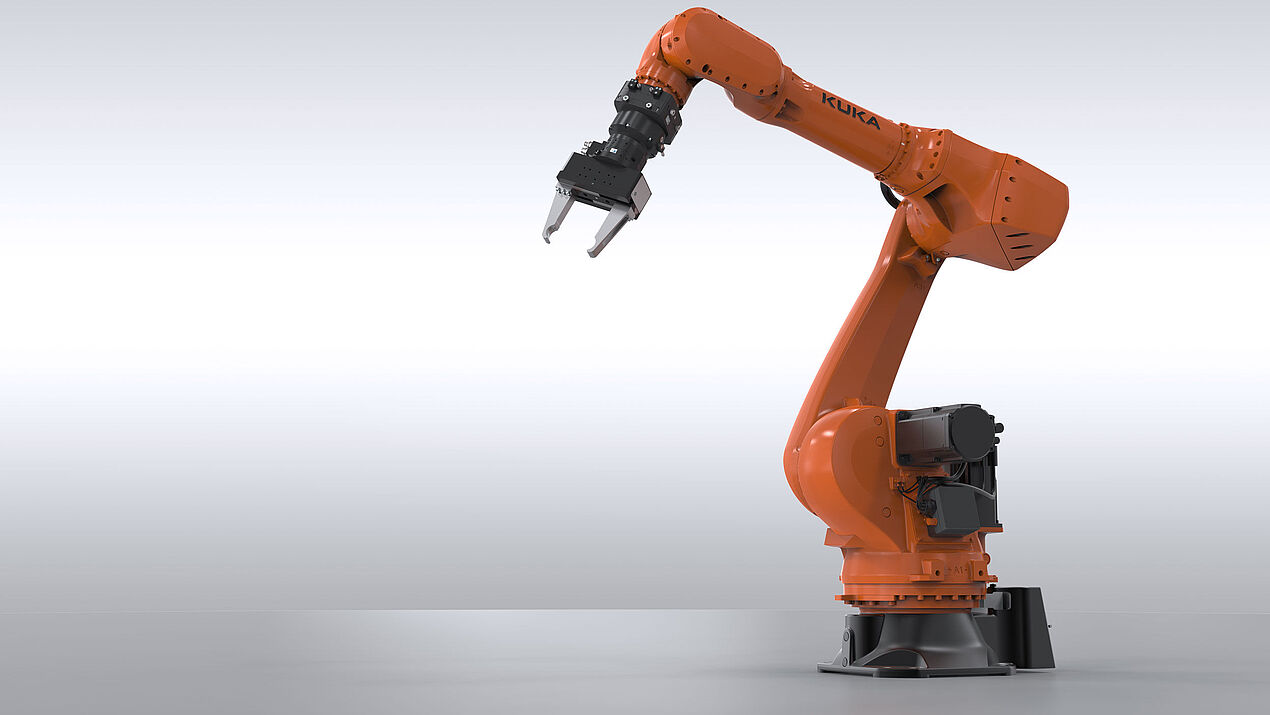

KUKA robotics

The challenges and requirements caused by the use of robots are becoming more and more varied, especially due to the wide range of tasks. KUKA offers the perfect balance between productivity and safety as part of robot-based automation, whether using high-performance industrial robots with different load capacities and ranges or collaboration robots for human-robot collaboration.

YOUR BENEFITS

- Productivity is boosted

- Quality assurance thanks to high precision

- Processes can be adapted and optimized flexibly

- Manufacturing costs are cut

- Complex production sequences can be automated

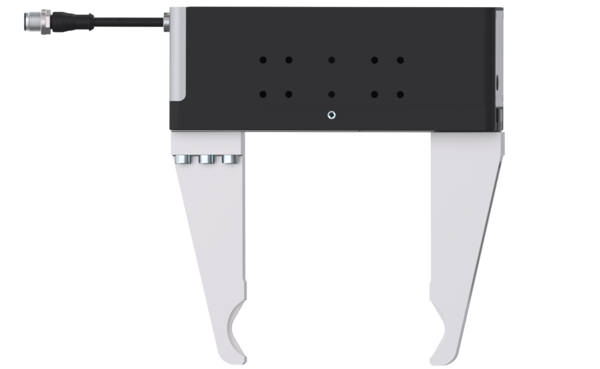

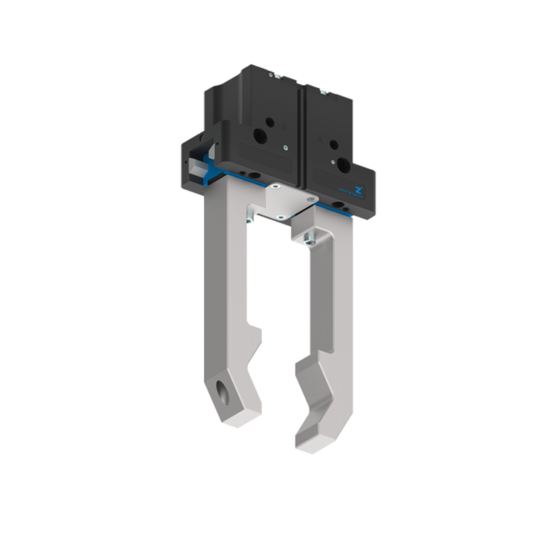

Flexibility and compatibility in END EFFECTOR selection

With the help of the large selection of handling accessories from the gripping and vacuum technology areas, the challenges and requirements for a wide range of application areas are covered and, together with KUKA robots, pave the way for automation – with maximum performance. In particular, the MATCH ecosystem ensures maximum compatibility and flexibility in handling thanks to the universal, robot-specific communication interface that is standardized to KUKA. This combines high speed with maximum precision. In addition to an extensive range of freely configurable robot accessories and handling technology from Zimmer Group, we offer compact, predefined solutions.

Application areas

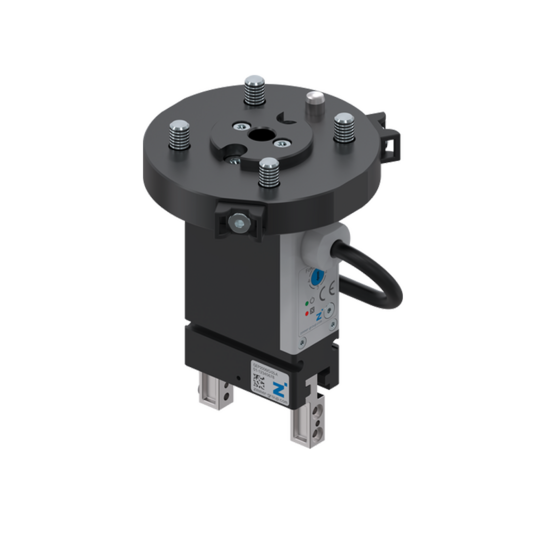

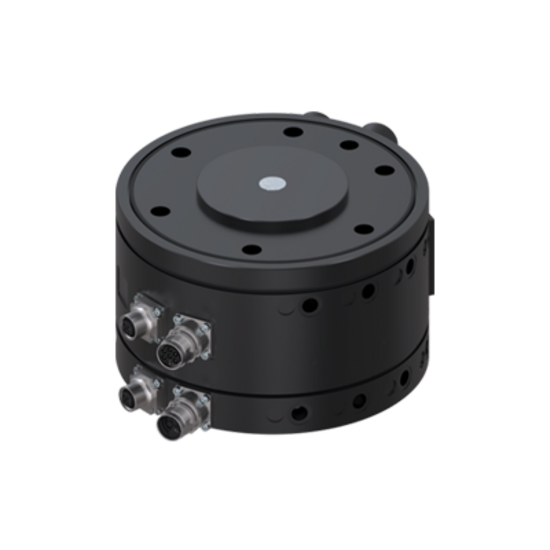

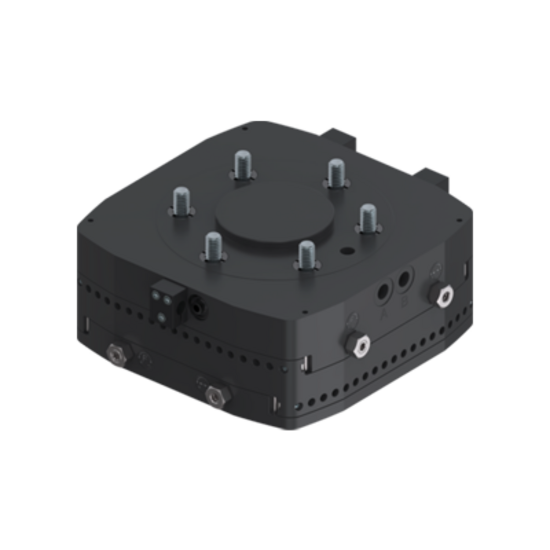

SMART COMMUNICATION MODULE FOR KUKA ROBOTS

Flexible and simple INTEGRATION WITH COORDINATED COMMUNICATION MODULES

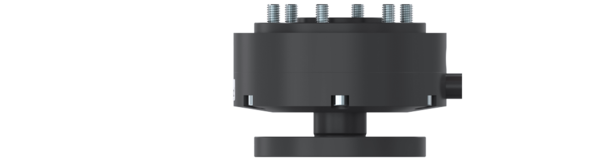

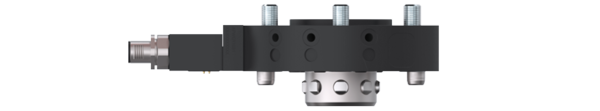

Thanks to the coordinated communication modules of the Zimmer Group, activating and integrating intelligent, mechatronic grippers with cobots and industrial robots from KUKA is as easy as can be. Here, the Smart Communication Module SCM from Zimmer Group translates the IO-Link communication interface into digital inputs and outputs (Digital I/O) and vice versa, thus ensuring data exchange to the robot control system for the most information possible.

No matter which grippers from Zimmer Group you have, all IO-Link gripper components can be used with the right adapter plate between the specific KUKA robot flange and ISO pitch circle. As a gateway for the end effector, the SCM – an integrated communication module – communicates with the robot control system. This ensures complete and simultaneously easy activation of the end effector, without losses and with maximum safety and reliability. The uniform interface ensures maximum compatibility with KUKA robots.

Convenient activation using the Comfort App

The combination of the Comfort App Lite and SmartPad from KUKA makes activation and commissioning of the gripper convenient and direct via the teach pendant, thus combining the advantages of an easy setup, including essential commands for efficient programming and smooth automatic operation. The commissioning and programming is supported by pre-stored function blocks, making a productive and reliable robot application possible. In collaboration, KUKA robots and Zimmer Group grippers provide the ideal conditions for optimal and precise robot-based automation.

What does KUKA offer as a robot manufacturer?

Johannes Landherr: "We supply load capacity classes from 3 to 1300 kilograms in conventional industrial robots, mobile robotics and are now fully active in the cobot area". Here, we have three models at Automatica (3 kg, 11 kg, and 15 kg load capacity)."

Zimmer Group: "Our MATCH ecosystem on the KUKA iisy – why?"

Johannes Landherr: "Exactly. When talking to our customers, we've found out that they are purchasing a robot and perhaps do not even know what they want to automate yet. They try out many different things and are definitely happy when they can switch between the grippers. Sometimes a clamping gripper, sometimes a suction gripper. The MATCH system is perfect for this."

Johannes Landherr: "Yes, that's exactly right."

Zimmer Group: "So, in that case, between the HRC gripper and the Schmalz suction cup? “

Zimmer Group: "And what are the future challenges for KUKA?"

Johannes Landherr: "The challenges are in making robots accessible for everyone, in moving the democratization of robots forward. A second area I see is cognitive robotics. Here, the robots have the versatility to adapt to changing environmental conditions, respond accordingly and generalize models so that external intervention is not required in all cases. These are two main points I definitely see in the future."

Zimmer Group: "Very good, thanks for the interview here at the KUKA booth."

ROBOTICS PRODUCT FINDER

Use the intelligent search and find the right accessories and end effectors for your system. Well-informed recommendations for selection and additional filters give you an overview of our wide product portfolio, while the practical display of the most important data helps you narrow down your search and find the perfect components for your requirements.

Gripper Product Finder

Are you looking for the perfect gripper? With our product finder, you will quickly find what you are looking for. Simply enter your application parameters and sort the selection by stroke, gripping force or drive force to get a better overview. Try it now!