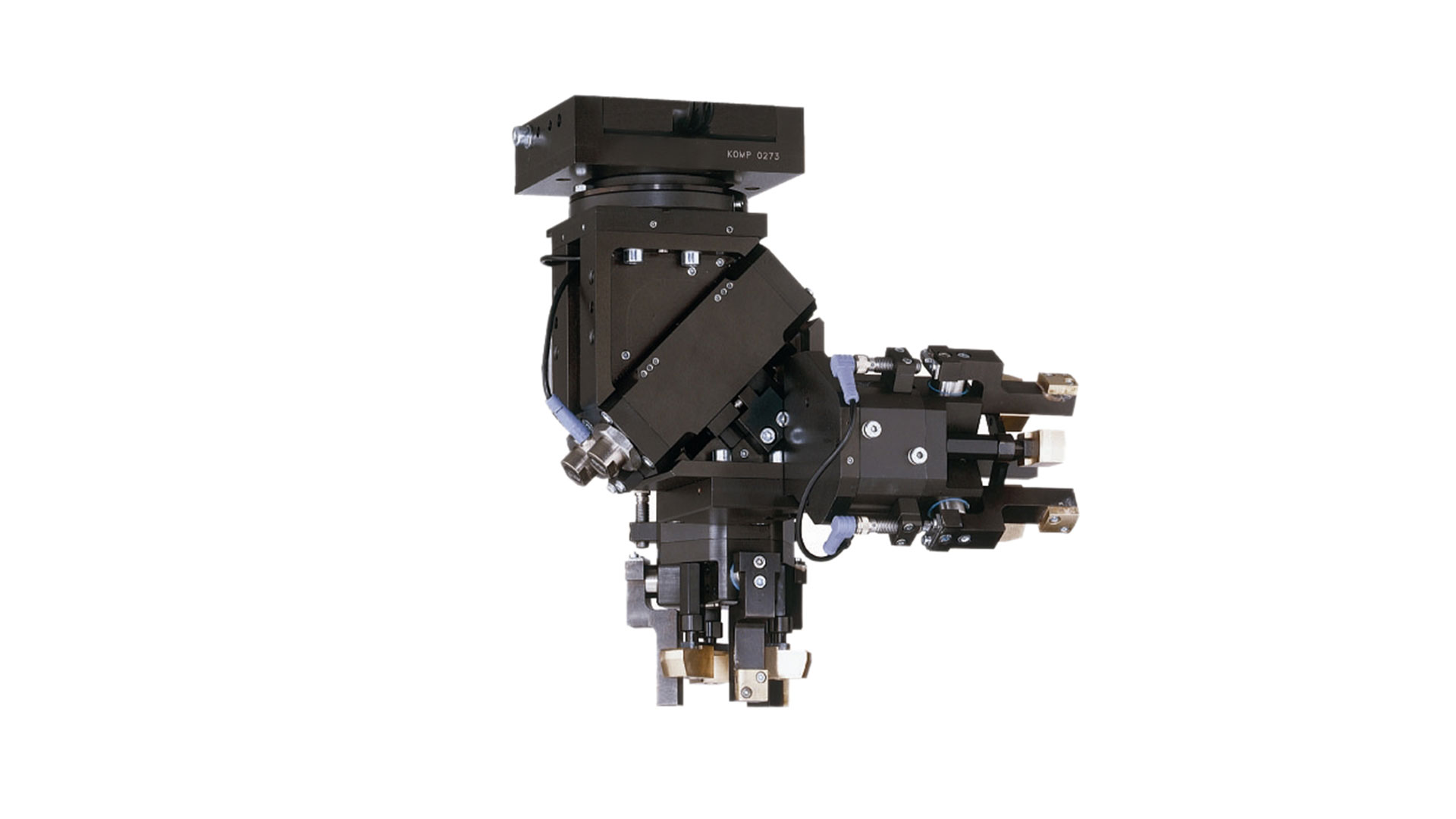

Gripper for turned parts

System solutions | Mechanical and plant engineering

Angle Pivot Units

Series SW

- Up to 100% more performance than the benchmark

- Includes two angle flanges

- More than 100% higher radial bearing load than the benchmark

3-Jaw Concentric Grippers

Series GD1700

- Up to 100% more performance than the benchmark

- Includes two angle flanges

- More than 100% higher radial bearing load than the benchmark

Space was needed for a double gripper in the tight machining space of a lathe. Due to the cycle time, a combined finished and unfinished part gripper that can pick up two workpieces at once was needed.

A double gripper based on standard Zimmer modules was used. In doing so, the gripper brings the blank part along with it in piggyback when removing the finished part. After the finished part is removed, only a brief swivel takes place. Afterwards, machining can resume immediately. The workpiece change takes only a few seconds. The spring-loaded pressure piece ensures correct placement against the plane face of the clamping tool. The integrated pneumatic feed-through ensures low interference contours. The parts that make contact with the workpiece are made of brass to protect the surface.

IP40

IP40 Pneumatic

Pneumatic Gripper jaws are synchronized

Gripper jaws are synchronized Gripping force safety device for spring

Gripping force safety device for spring

| Drive type | PNEU |

| Max. gripping force | 1000 [N] |

| Gripping concept | KRAFT |

| Gripping safety device | FED |

| Max. stroke | 12 [mm] |

| IP class | IP40 |

| System weight | 8 [kg] |

| Max. workpiece weight | 8 [kg] |

| Max. workpiece temperature | 80 [°C] |