System reference

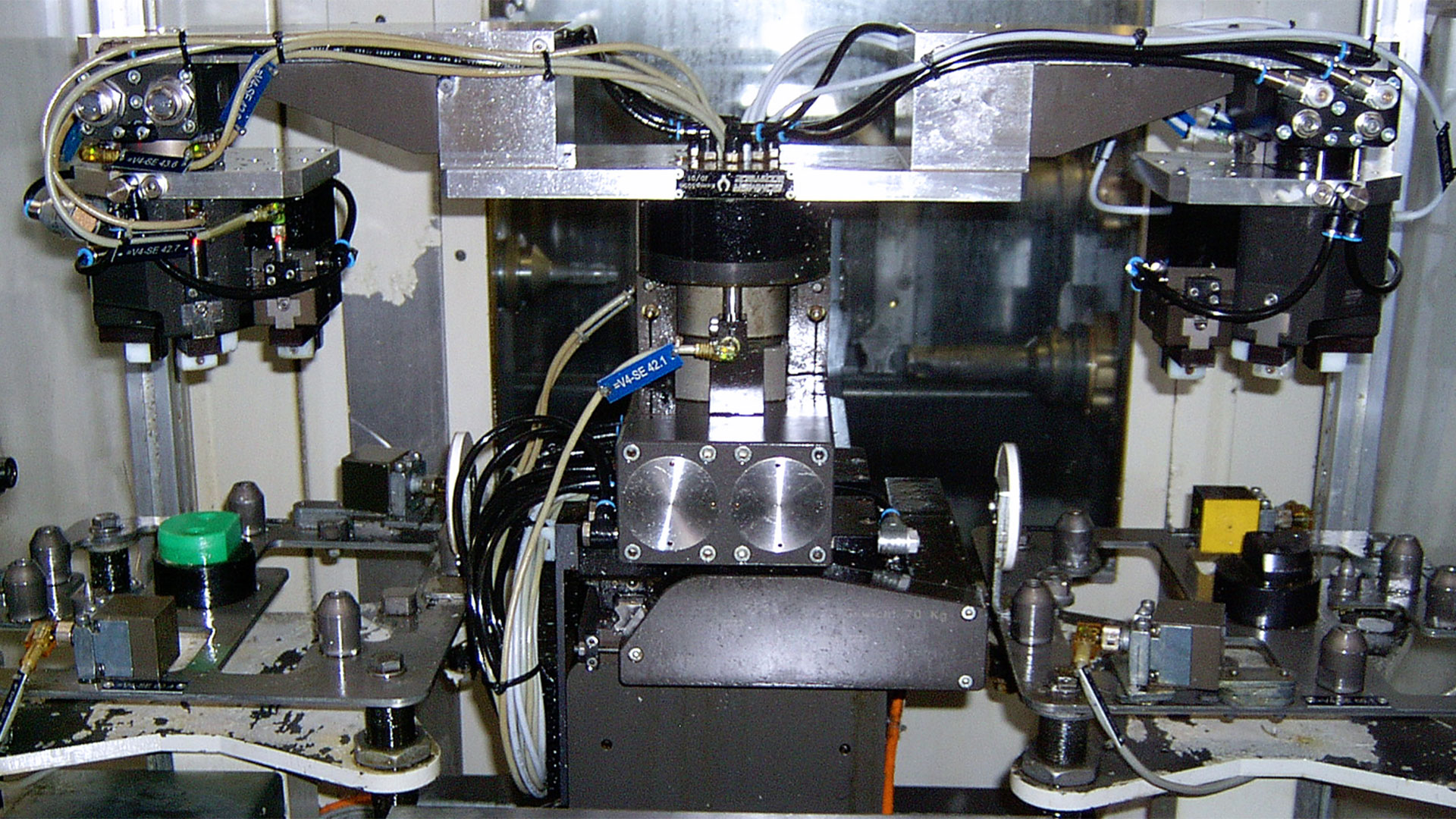

Gripper for loading machines

Swivel and rotary modules | System solutions | Mechanical and plant engineering | Metal | Machining

Flat Swivel Units

Series SF-C

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

3-Jaw Concentric Grippers

Series GD300

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

2-Jaw Parallel Grippers

Series GP400

- High gripping force as a result of optimal direction change of driving force into gripping force

1. Swivel and rotary modules

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

2. 3-jaw concentric grippers

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

3. 2-jaw parallel grippers

- High gripping force as a result of optimal direction change of driving force into gripping force

Challenge

This application example involves the internal loading and unloading of tooling machines (milling machine). The tight installation space and the fact that workpieces were to be provided outside of the machining space were special challenges.

Solution

The tasks was accomplished by a servo-electric loading Z-stroke and a pneumatically driven swivel unit with a center position. Furthermore, an integrated tubeless pneumatic feed-through ensured low interference contours.

Highlights and technical data

IP40

IP40 Pneumatic

Pneumatic External gripping

External gripping Gripping force safety device for spring

Gripping force safety device for spring

Technical Data

| Drive type | PNEU |

| Max. gripping force | 6400 [N] |

| Gripping concept | KRAFT |

| Gripping safety device | FED |

| Max. stroke | 20 [mm] |

| IP class | IP40 |

| System weight | 70 [kg] |

| Max. workpiece weight | 8 [kg] |

| Max. workpiece temperature | 80 [°C] |