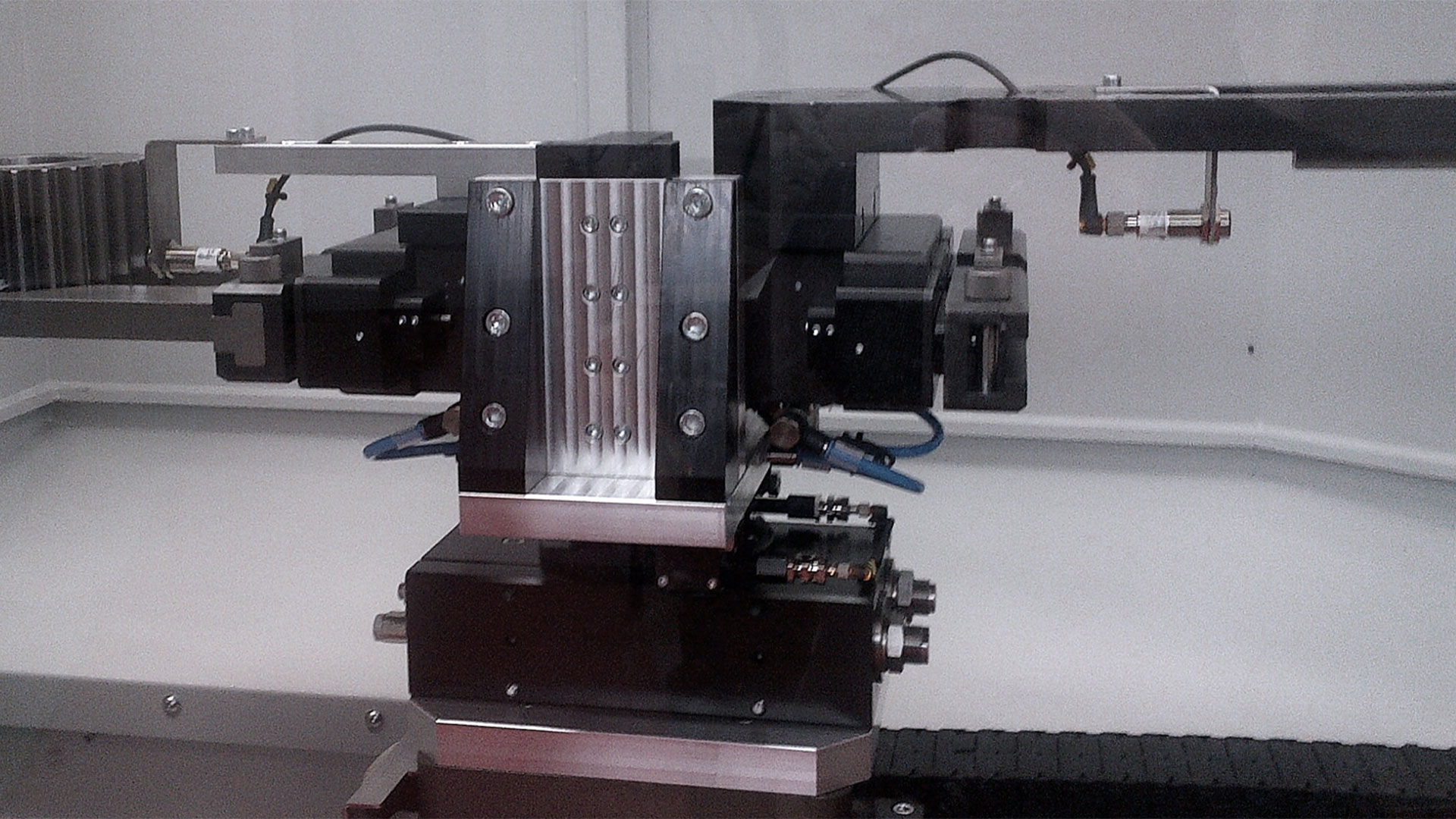

Gear loading station

Swivel and rotary modules | System solutions | Mechanical and plant engineering | Metal | Machining

Flat Swivel Units

Series SF-C

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

2-Jaw Parallel Grippers

Series GP400

- High gripping force as a result of optimal direction change of driving force into gripping force

- Smooth power absoption due to hydraulic shock absorber with spiral groove technology

- Torque up to 130 Nm

- Compact flat swivel units with 3 positions available

- High gripping force as a result of optimal direction change of driving force into gripping force

In a loading and unloading unit of a tractor manufacturer, semi-finished products (gear wheels) needed to be inserted into a hydraulic expansion chuck of a grinding machine. Other challenges included the machine's internal loading and unloading over a distance of two meters, short cycle times and a large range of components.

A loading concept was developed as a solution. It consisted of a two-meter servo axis for loading/unloading, a rugged but sensitive XYZ axis compensation module for placing the gear wheels on a clamping mandrel and a 180° swivel unit for changing between semi-finished and finished parts. The large range of components was made possible by a gripper jaw quick-change system.

IP40

IP40 Pneumatic

Pneumatic Drive AC servo motor

Drive AC servo motor Gripping force safety device for spring

Gripping force safety device for spring

| Drive type | PNEUELE |

| Max. gripping force | 3100 [N] |

| Gripping concept | FORM |

| Gripping safety device | FED |

| Max. stroke | 40 [mm] |

| IP class | IP40 |

| System weight | 250 [kg] |

| Max. workpiece weight | 15 [kg] |

| Max. workpiece temperature | 80 [°C] |