EOAT and gripper systems for foundry processes

With over 30 years of experience in the development of end-of-arm tooling (EOAT) for foundry and forging automation, we offer solutions that master even the most complex challenges. Our customized EOAT systems are designed to maximize efficiency and flexibility in your production. Regardless of the size of your foundry or forge, our innovative gripping solutions not only reduce labor costs, but also increase your company’s productivity and competitiveness. Rely on our expertise to take your automation processes to the next level.

Our know-how includes:

- Knowledge of the specific requirements in foundries

- Solving complex manual and hazardous tasks with gripper systems

- Preliminary studies to check feasibility

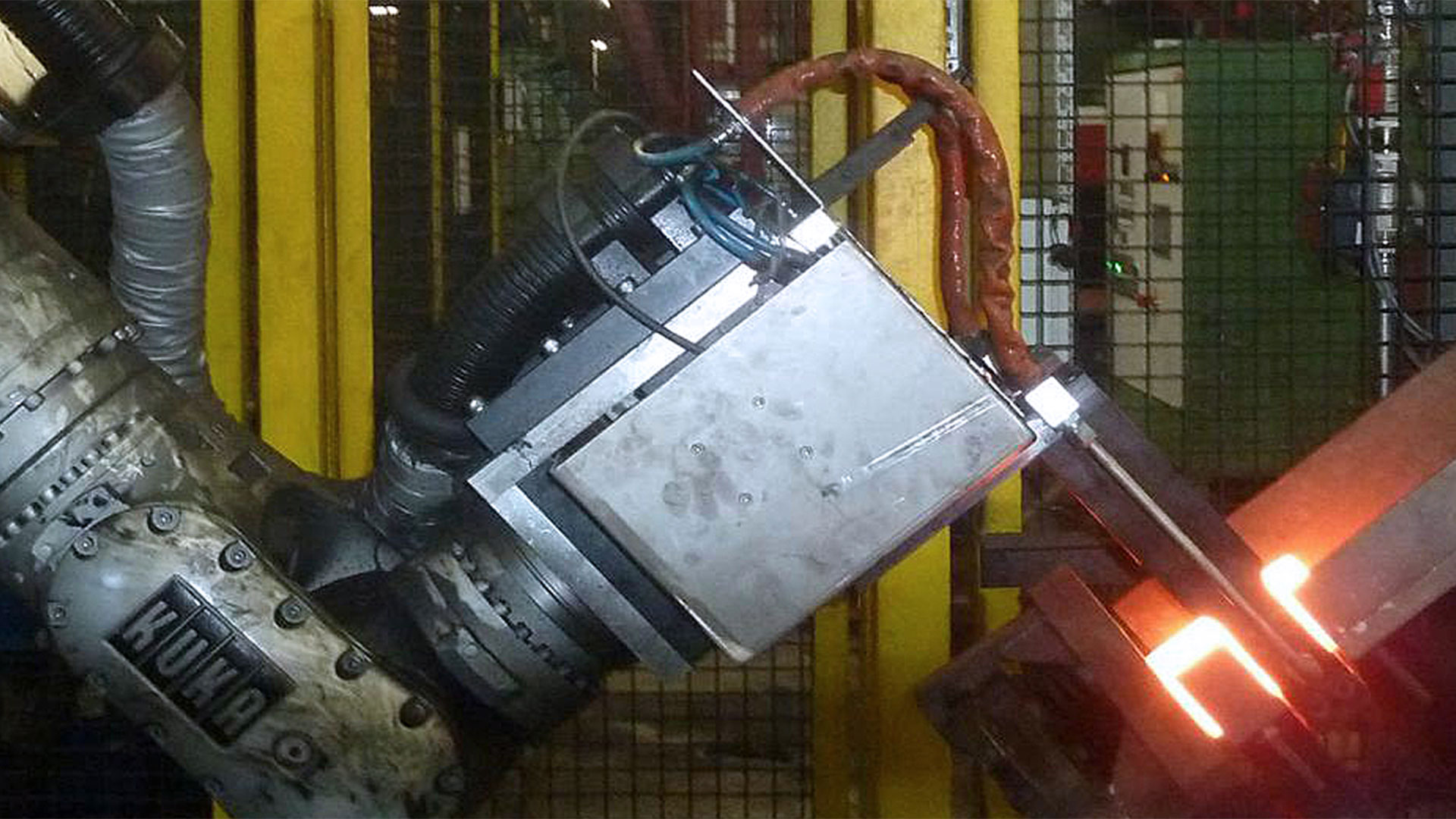

High temperatures – our solution

Rely on our expertise in automation and benefit from solutions that are optimally tailored to the special requirements of foundries – for maximum efficiency and process reliability.

- IP protection class: Specially sealed products guarantee complete protection against the most adverse environmental conditions.

- Performance level and safety: Maximum safety for the user and the machine thanks to proven safety principles.

- Extensive product range and many years of expertise: Our developers’ knowledge of the industry and years of experience ensure process reliability and high availability even in adverse environmental conditions.

Our EOAT product range covers the automation of the following processes:

- Die casting: Casting process for series production

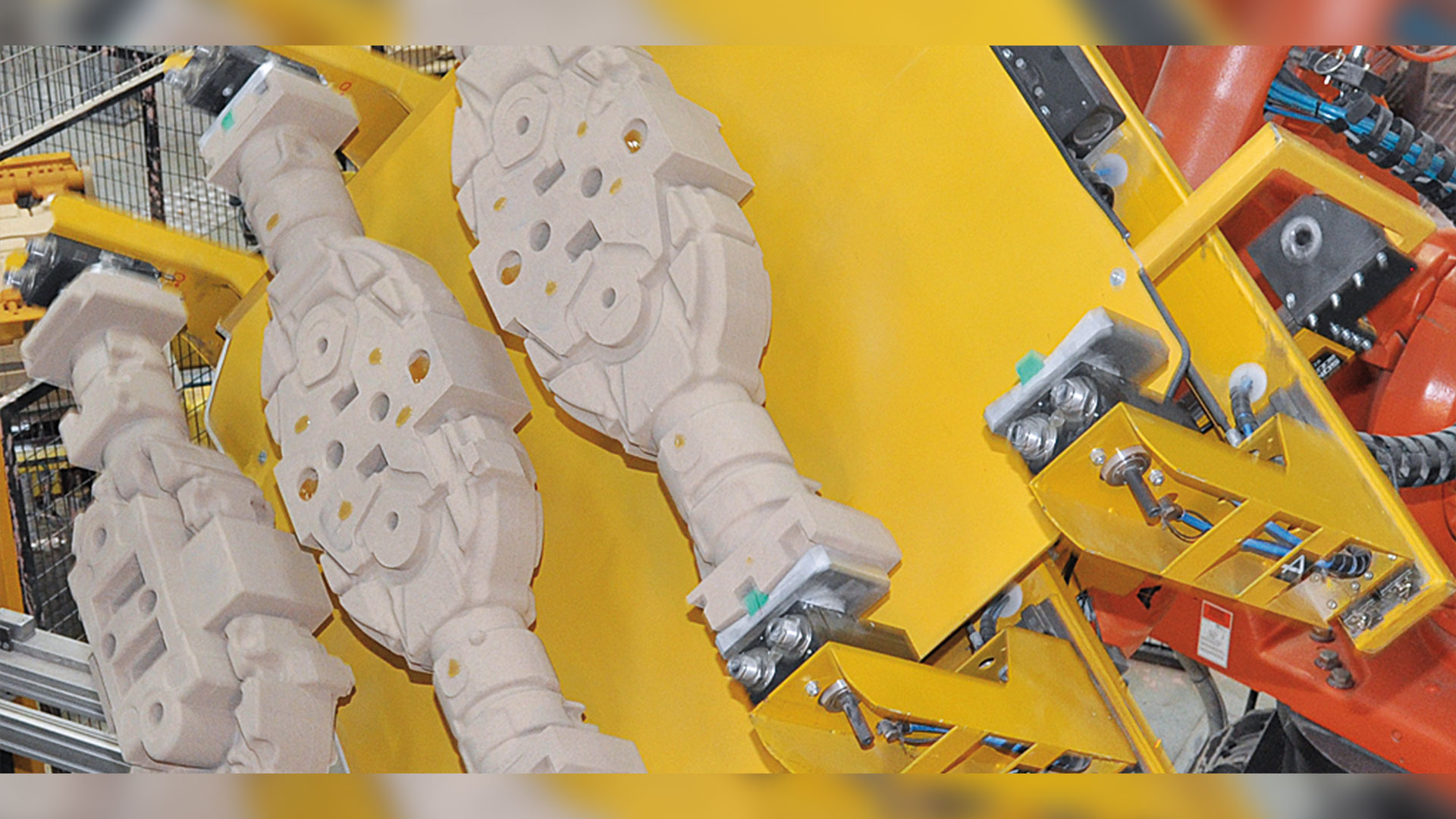

- Sand casting: Casting process using sand

- Investment casting: Casting process for the smallest cast parts

- Forging: Forming metal parts with presses and hammers

- Fettling: Reprocessing cast parts